- 13 -

KALVIS-4 (N) EN 2019.01.14

5.3. Connection to the heating system

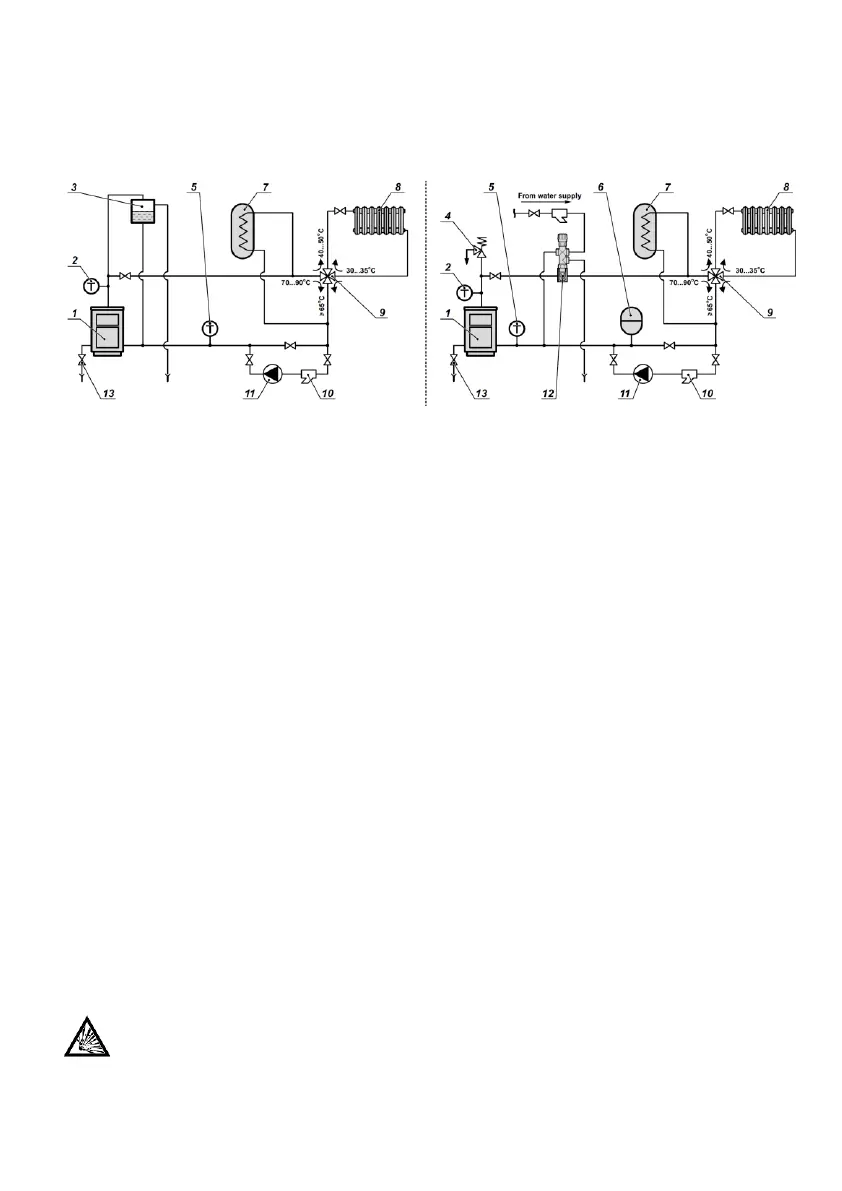

Requirements for connection (see fig. 6a, 6b):

Recommended connection design options:

Fig. 6a: open type heating system; fig. 6b: closed type heating system.

1. Boiler. 2. Thermomanometer *. 3. Open expansion vessel. 4. Protective valve.

5. Thermometer. 6. Expansion vessel. 7. Boiler. 8. Coils 9. Quadruple mixing valve. 10. Water

filter. 11. Pump. 12. Emergency cooling valve. 13. Filling-discharge pipe.

* Boiler is completed with thermomanometer, with accurateness and response time in line with

its measuring functions.

Requirements for connection:

• The boiler must be connected to the heating system according to a project

prepared by the heat engineering technicians or the work can be carried out

independently by a highly skilled plumber, experienced in the work and

well-familiar with this description.

• Connect the boiler to heating and return pipes with a diameter of at least

1½ in.

• When connecting the boiler to an enclosed heating system with a

membrane expansion vessel, its permissible pressure can be up to 10 bar,

the air pressure must be equal to the pressure in the system, e.g. 0.6 bar.

An open-ended expansion tank can be fitted in place of the membrane

expansion vessel when developing an open-type heating system.

• A safety valve (G½B) must be fitted into the system as close to the boiler

as possible, protecting the boiler housing from pressures greater than

1.5 bar (0.15 MPa). There must be no closing valves between the boiler

and the safety valve.

• If the system has valves disconnecting the boiler from heating

system installed, they must be fully open. On order to avoid a mishap,

after opening the valves, remove their handles to safe place.

Loading...

Loading...