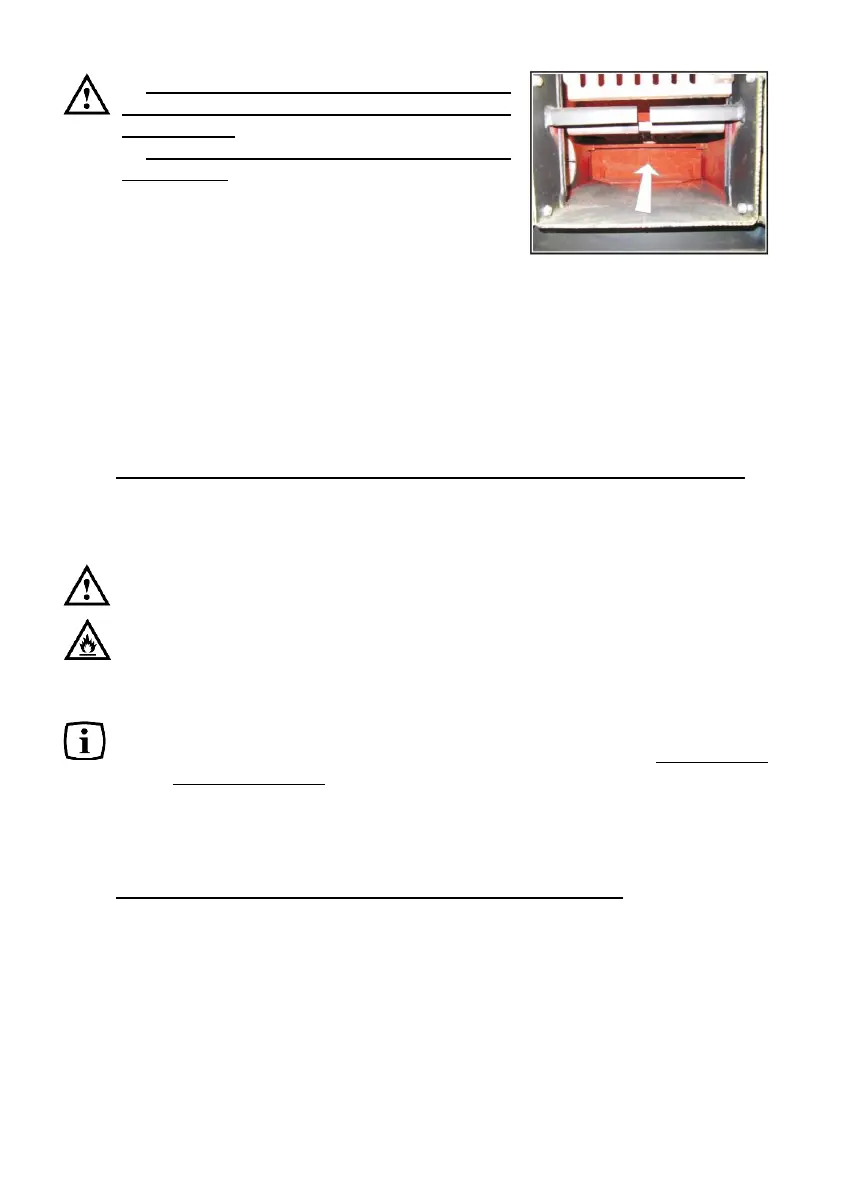

After installation and each cleaning of

the boiler make sure that the ash cleaning

lid is closed.

Combustion and draft efficiency de-

pends on it.

Fig. 11.

We advise, before the start of heating season and at least every 3 months

during the heating season, clean the boiler connection flue pipe and chimney.

Check fuel pipe connection status, look for leaks, eliminate them if found.

6.8. Frequently asked questions

I. What can happen in the case of electric power failure during stoking?

Without forced water circulation, there is the danger of water boiling;

boiler overheating; if safety valve is in bad order boiler or pipeline may

explode; boiling water may cause injuries.

a) Reduce burning intensity: close air supply valve; as far as possible

close the smoke draft valve but don’t let smoke to enter the room.

b) In the case of emergency, extinguish the boiler by removing fuel from

the combustion chamber (for there was less smoke in the room, put

burning fuel into a container with water, open doors and windows).

Don’t pour water into the combustion chamber, this may cause

irreparable damage to the boiler.

c) When emergency is over, when pressure in the system drops down,

refill the boiler and heating system with technical water, only after the

boiler cools down.

d) In winter, when there is no electric power for longer period and there

is danger of freezing, discharge water from the system.

II. Why, when stoking, strange (boiling) sounds are heard?

The boiler is operating at a higher than nominal capacity, the circulation

pump operation is disturbed, the pressure in the heating system is too

low.

a) Check that the air draft controller is correctly adjusted or not set at too

high temperatures.

b) Check that the chimney draft is not too large, close smoke draft valve.

c) Water circulation may have stopped: check the circulation pump for

operation; is the water level (pressure) in the system sufficient;

whether the system is properly deaerated; are there closed system

valves or there are clogged water filters.

Loading...

Loading...