- 19 -

KALVIS-4 (N) EN 2019.01.14

During stoking of the boiler, make sure that both the combustion chamber

and fuel loading doors were tightly closed. During intense stoking, don’t open

them.

In the case of incorrect operation of the boiler, unsuitable fuel or low

chimney draft, valves located in the chimney can get stuck, so, during every

stoking, move the valves: open and close several times all the valves of the

boiler.

6.6. Boiler extinguishing

In the case of normal operation, the boiler extinguishes itself, when the

fuel load burns out. If forced extinguishing is needed, first of all remove fuel

from the combustion chamber.

Put burning fuel into a container with water for less smoke generated in

the room.

In the case of forced extinguishing, open doors and windows to ensure

adequate ventilation.

6.7. Boiler cleaning

Ash, accumulated under the firegrate, can prevent air from entering the

combustion chamber. Therefore, at least before every second firing, remove

ash from the ash box and extract the remaining ash from the ashtray.

Clean the boiler, remove ash drawer and extract the remaining ash

only after the boiler has completely extinguished and cooled.

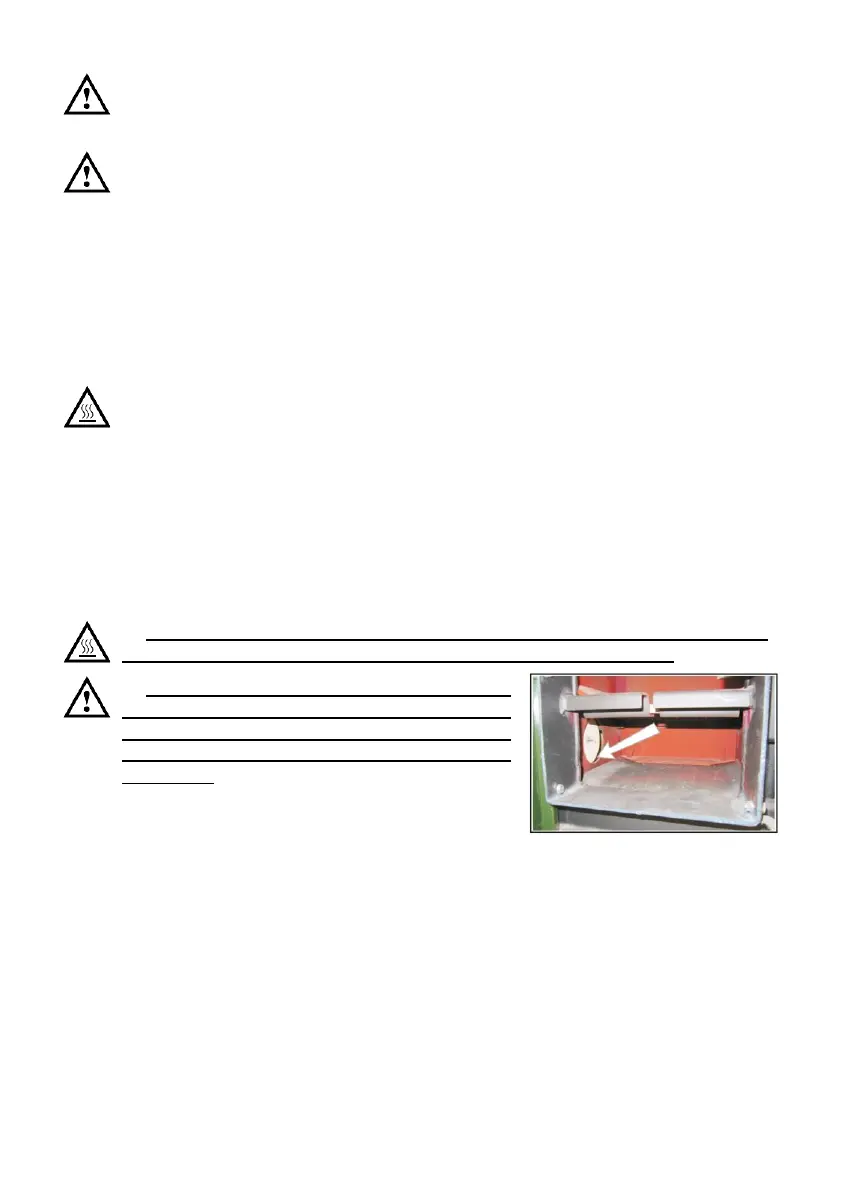

Protect the air draft valve on the side of

the ashtray from dropping ash which can

hinder the valve operation resulting in

poor combustion and difficult boiler

operation.

Fig. 10.

In order to ensure efficient boiler operation, periodically clean soot away

from boiler internal surfaces. Intervals between the cleaning depend on fuel

quality (especially moisture), stoking intensity, chimney draft and other

circumstances. We recommend cleaning boiler heat exchanger and

combustion chamber when the soot layer is up to 3 mm, but at least monthly.

Remove accumulated ash and soot. When cleaning, remove the rings and

thoroughly clean internal planes of the boiler.

Remove ash and soot by opening the combustion chamber door,

removing ash drawer and cleaning lid behind the drawer.

Loading...

Loading...