4

B. J3 – Armature Current – Select the J3 position (1.7, 2.5, 3.3, 5, 7.5) closest to the rated

motor current. (Note the maximum output current is set to 150% of the J3 position, which

may be readjusted using the FWD CL and REV CL trimpots.)

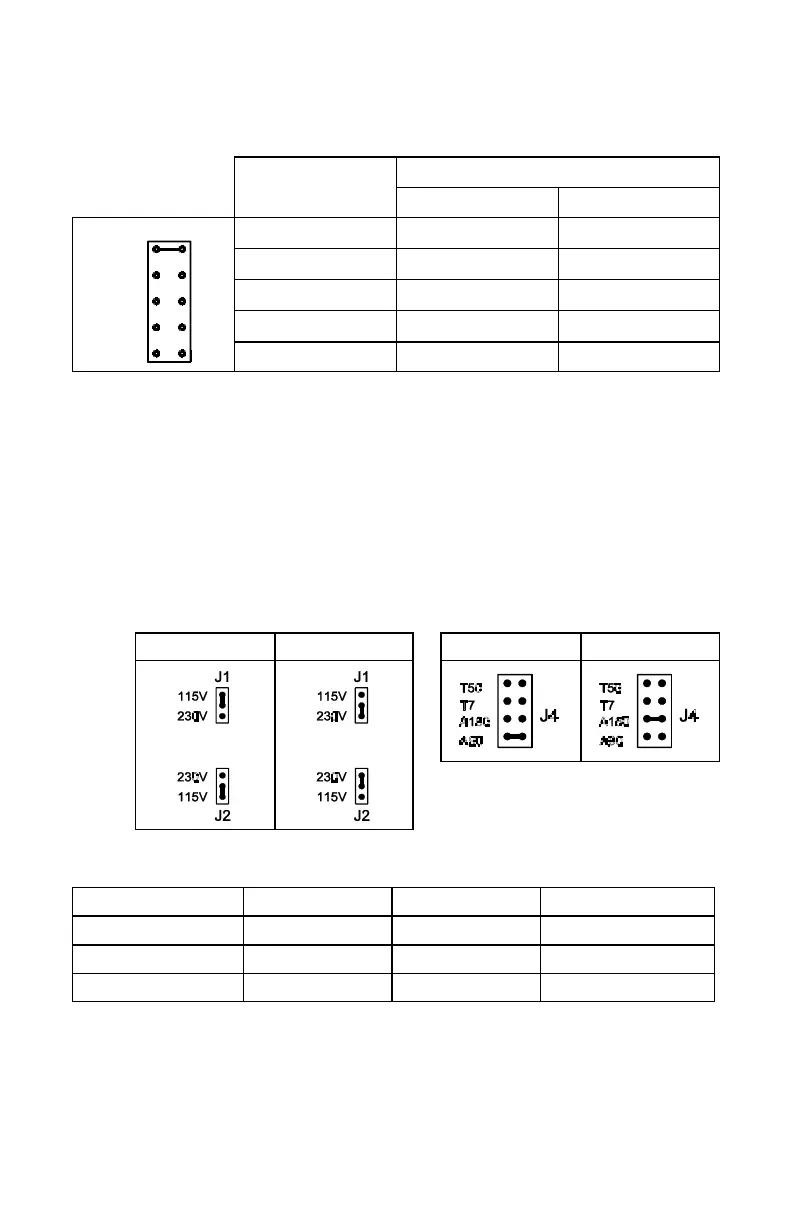

TABLE 4 – JUMPER J3 POSITION vs MOTOR HORSEPOWER

Jumper J3 Position

Motor Current

(DC Amps)

Motor Horsepower

90VDC 180VDC

7.5A 3/4 1

5.0A

2.5A

1.7A

3.3A

7.5A

J3

5.0A 1/2 1

3.3A 1/3 3/4

2.5A 1/4 1/2

1.7A 1/6 1/3

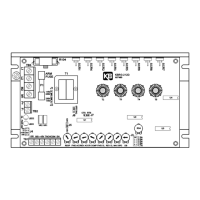

C. J4 – Motor Armature Voltage – Select the desired armature voltage by placing J4 in the

proper position, “A90" or “A180.” Note: For 115 volt AC Line input, the armature

voltage must be set to “90.” For 230 input, the armature voltage is normally set for

“180.” However, it is also possible to set the armature voltage to “90" for step-down

operation. (See fig. 2 and table 5.) Note: Jumper J4 is also used if tach-generator

feedback is to be used. (See fig. 2)

If a 7 volt per 1000 RPM tach-generator is used, place jumper J4 into the “T7" position.

For a 50 volt per 1000 RPM tach-generator, place the jumper into the “T50" position.

Note: When using tach-generator feedback, the IR Comp trimpot should be turned to a

minimum setting (full CCW).

FIG. 1 – AC LINE VOLTAGE

JUMPER SETTING

FIG. 2 – MOTOR ARMATURE

VOLTAGE JUMPER SETTING

115VAC 230VAC 90VDC 180VDC

TABLE 5 – RELATIONSHIP of AC LINE INPUT AND MOTOR

VOLTAGE with J1, J2 and J4 JUMPER POSITION

AC INPUT VOLTAGE J1, J2 POSITION J4 POSITION MOTOR VOLTAGE

115 115 90 90

230 230 180 180

230 230 90* 90*

*A 90VDC motor can be used with a 230VAC line. However, speed range may be reduced and

motor derating may be required.

Loading...

Loading...