15

Note: If Jumper J3 is set to the “T7” or “T50” position, a tach-generator must be wired to

Terminal Block TB3. If a tach- generator is not used, Jumper J3 must be in either the

“A180” or “A90” position. If jumper J3 is in the “T7” or “T50” position, and a tach-gener-

ator is not used, the motor will accelerate to full speed and the Main Speed Potentiometer

will not control speed.

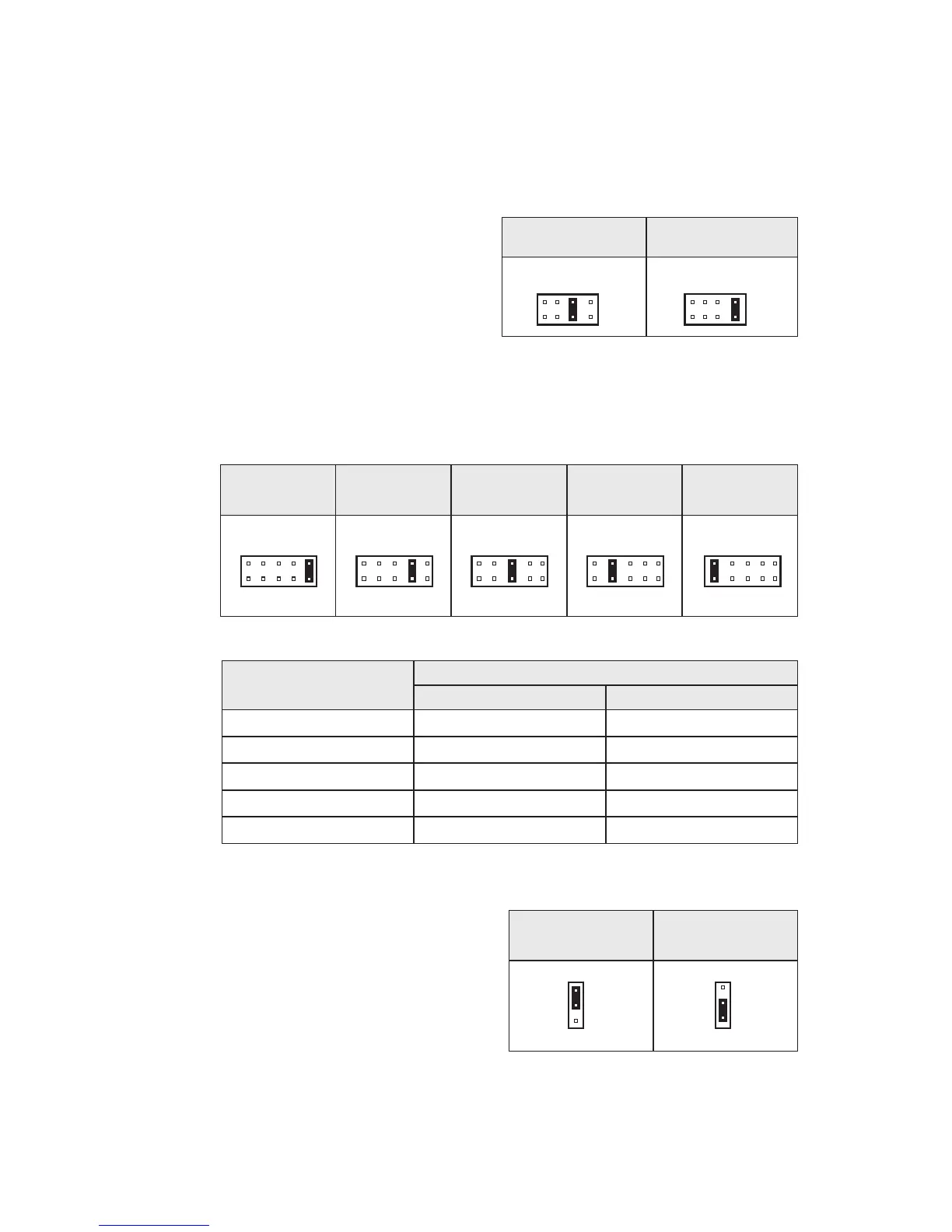

C. DC Tach-Generator Voltage Selection

(J3) – Jumper J3 is factory set to the

“A180” position for 180 Volt motors.

When connecting a tach-generator to

Terminal Block TB3, set Jumper J3 to the

corresponding voltage of the tach-gener-

ator being used. See Figure 19.

Note: If using a tach-generator other

than 7V or 50V per 1000 RPM, see

Section IIIK, on page 13.

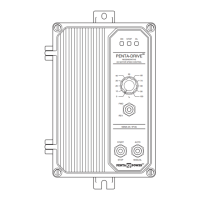

D. Motor Current Selection (J4) – Jumper J4 is factory set to the “10A” position for 10 Amp

motors. For lower current motors, set Jumper J2 to the corresponding current of the

motor being used. See Figure 20 and Table 6.

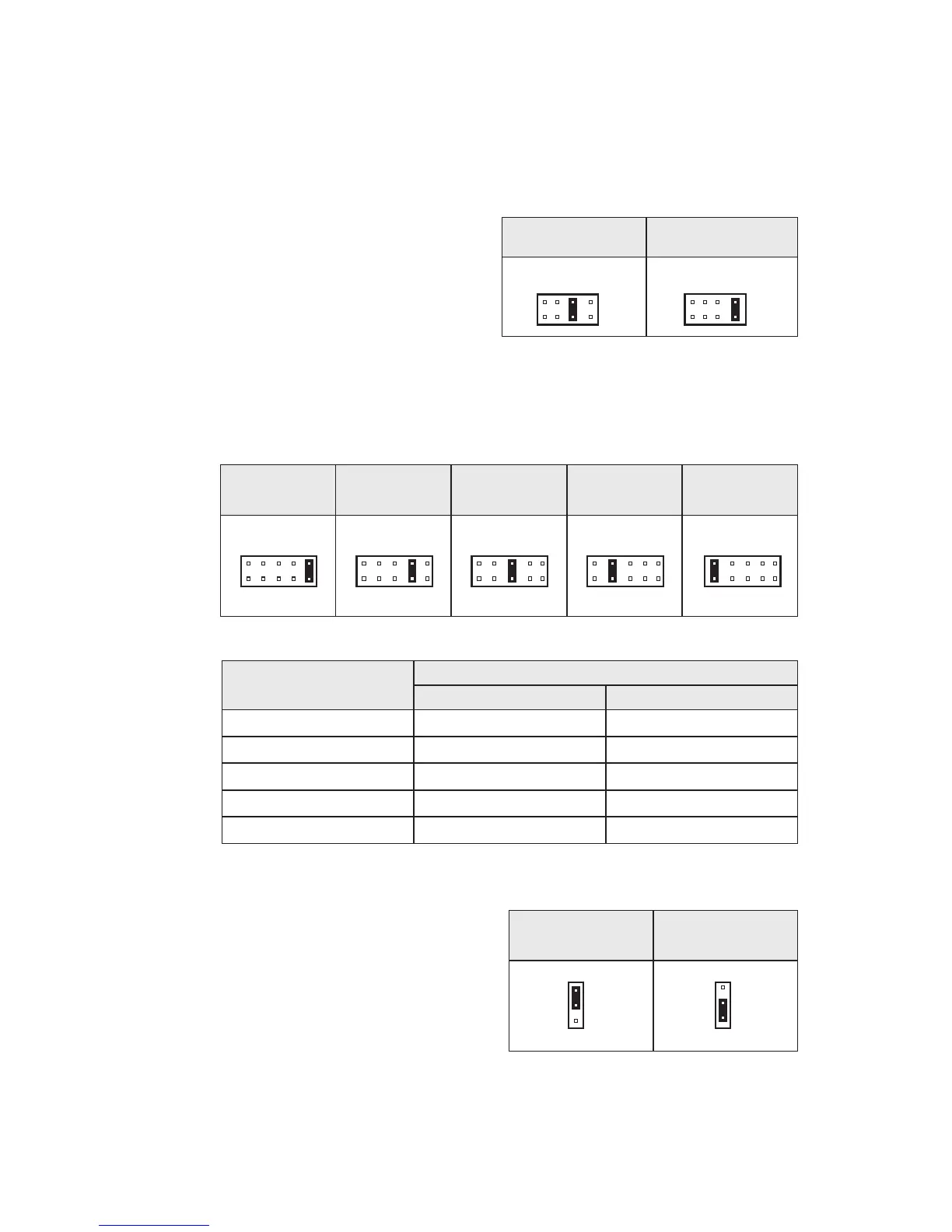

E. Analog Input Signal Voltage Selection

(J5) – Jumper J5 is factory set to the “15V”

position for use with a potentiometer to

control motor speed. To control motor

speed using a 0 - ±10 Volt DC isolated

analog signal voltage set Jumper J5 to the

“10V” position. To control motor speed

using a 0 - ±15 Volt DC

isolated analog

signal voltage, set Jumper J5 to the “15V”

position. See Figure 21.

Note: Connect the isolated signal voltage

to SIG (signal) and COM (-) terminals. If an isolated analog signal voltage is not avail-

able, install the optional Signal Isolator SIRC (P/N 8842).

J3 Set for 7V per 1000

RPM Tach-Generator

J5 Set for

0 – ±10 Volt Input Signal

J5 Set for

0 – ±15 Volt Input Signal

(Factory Setting)

J3 Set for 50V per 1000

RPM Tach-Generator

Loading...

Loading...