Note: If the IR compensation is too high, unstable (oscillatory) operation will result. If the

control is used with a DC tach-generator, the IR trimpot should be set fully counterclock-

wise.

To Calibrate the IR Trimpot:

1. Run the motor at approximately 30 - 50% of rated speed at no load and measure the

actual speed.

2. Load the motor to the rated current. Adjust the IR trimpot so that the loaded speed is

the same as the unloaded speed measured in step 1.

F. Response (RESP): Sets the relative response of the control.

The RESP trimpot is factory set to 50% rotation. For faster

response, rotate the RESP trimpot clockwise. For slower

response, rotate the RESP trimpot counterclockwise. See

Figure 40. Note: If response is made too rapid, unstable, oscil-

latory operation may result.

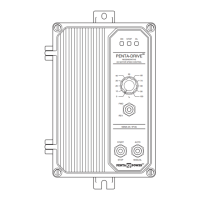

G. Deadband (DB): Sets the amount of Main Speed

Potentiometer rotation required to initiate control voltage out-

put. The DEADBAND trimpot is factory set to 0.5% of base

speed. For more deadband, rotate he DB trimpot clockwise.

For less deadband, rotate the DB trimpot counterclockwise.

See Figure 41 and Figure 42.

The DB trimpot also determines the amount of delay that will

occur before regeneration begins. (Regeneration occurs

when the applied load torque is in the same direction as the

motor rotation.)

To Calibrate the DB Trimpot:

1. Set the Main Speed Potentiometer to the zero speed

position.

2. Set the DB trimpot fully

counterclockwise.

3. Adjust the DB trimpot

until motor hum is elimi-

nated.

Note: If the DB trimpot is set

too low (counterclockwise

position), the motor may

oscillate between forward

and reverse directions.

Adjust the DB trimpot clock-

wise until the instability dis-

appears. (Oscillation may

also occur due to the setting

of the RESP trimpot. See

Section VIIIF.)

H. Timed Current Limit (TCL) – Sets the time for the control

to shut down after being in current limit (provides electron-

ic motor burnout protection). The TCL trimpot is factory set

for 5 seconds. To increase the TCL setting, rotate the TCL

trimpot clockwise. To decrease the TCL setting, rotate the

TCL trimpot counterclockwise. If the control remains in CL

for a predetermined amount of time (set by the TCL trimpot

and if Jumper J8 is in the “TCL” position), the control will

shut down.

21

Loading...

Loading...