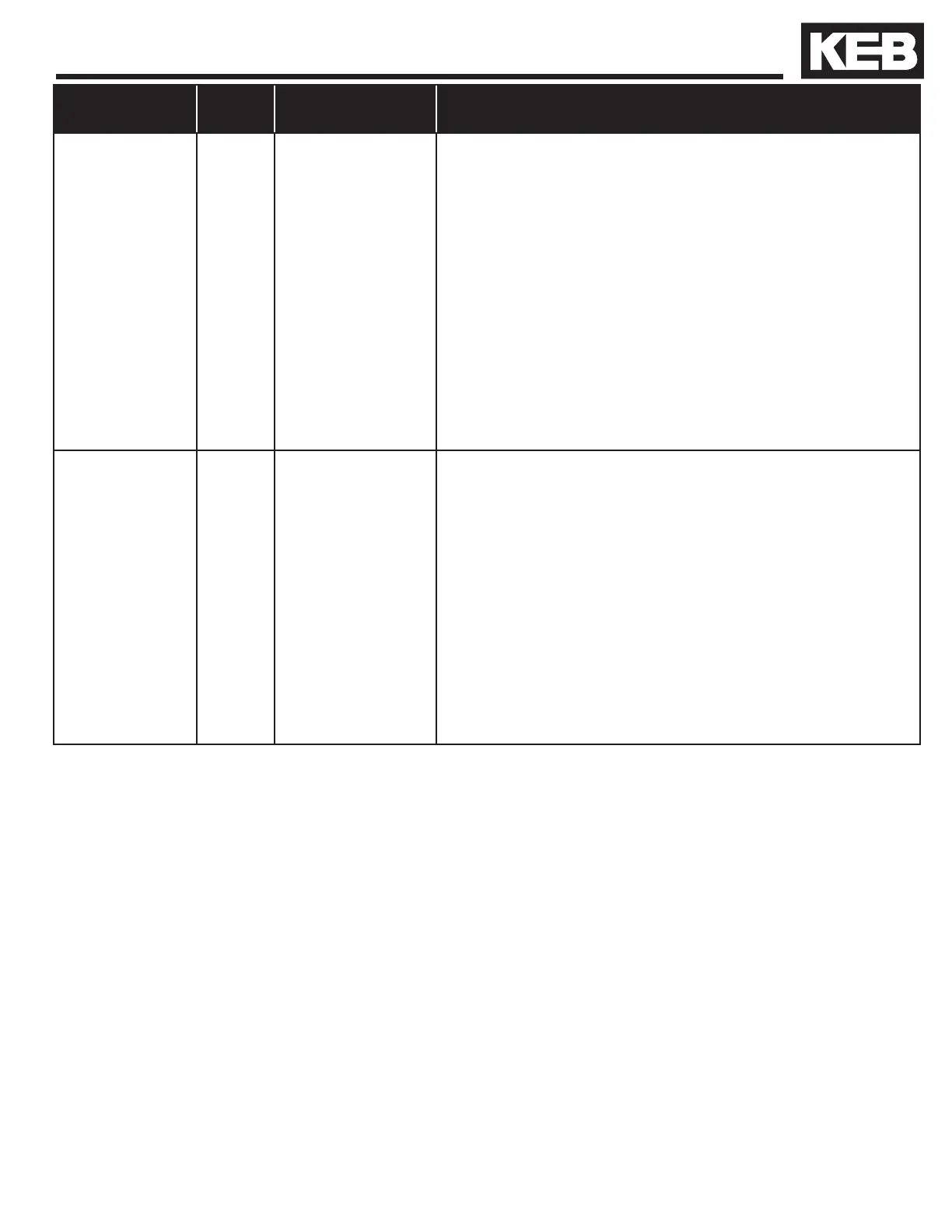

13

Error/Message Alt. /

(NUM)

Description Cause/Solution/Troubleshoot

Error Motor

Protection

EOH2

(30)

Electronic

Motor Overload

protection was

activated

Current can be monitored in CP30. Possible causes:

Incorrect motor data

Incorrect encoder data (closed loop only)

Torque boost too high or too low

High mechanical load/issues (friction)

Check:

CP12 Electronic Motor Overload Protection Current

(should match motor nameplate)

Motor Data

CP20 Encoder pulse number

CP21 Swap Encoder Channels

Mechanical load/issues (friction)

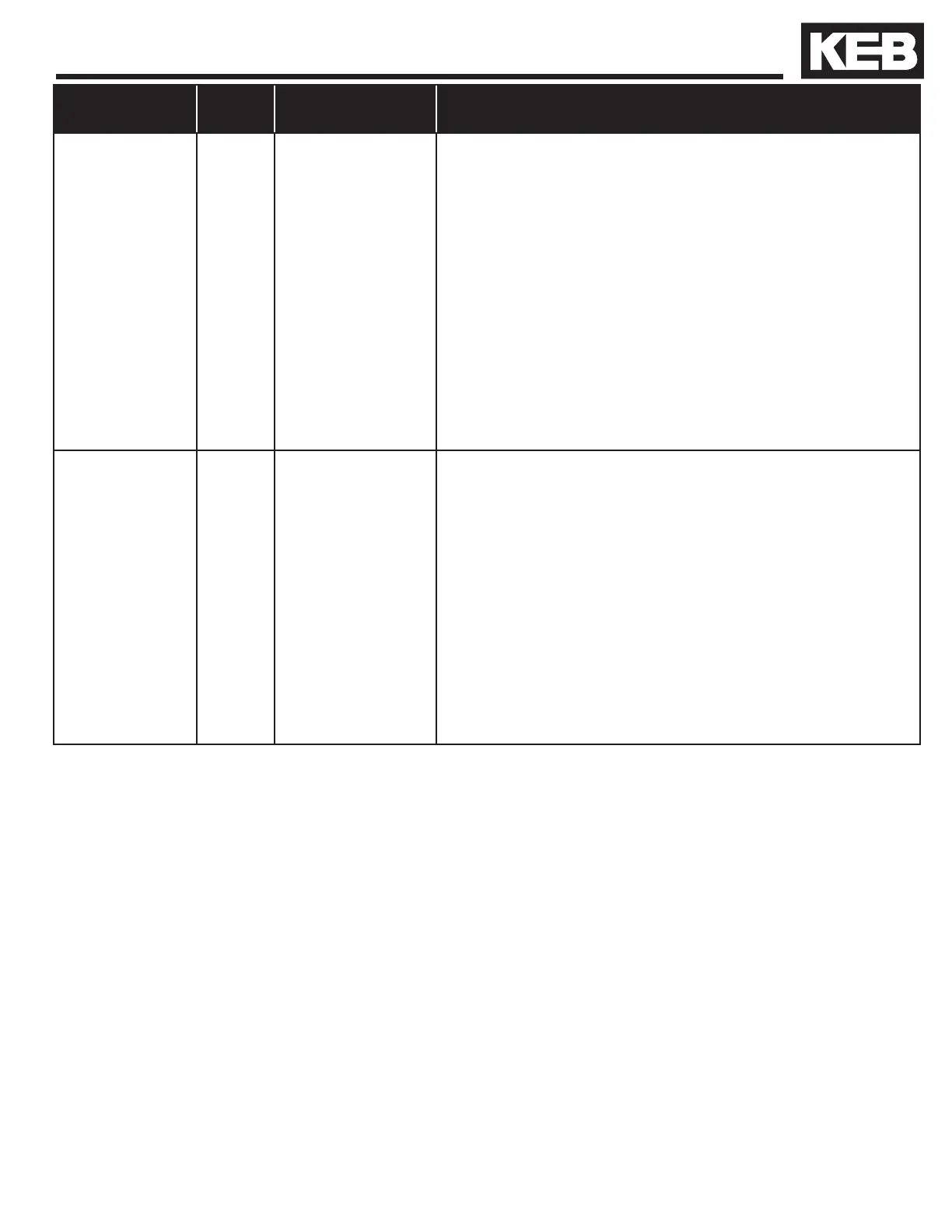

Error Overload EOL

(16)

Time dependant

overload. Error

cannot be reset

until display

shows E.nOL

Current can be monitored in CP30. Possible causes:

Excessive current

Incorrect motor data

Incorrect encoder data (closed loop only)

High mechanical load/issues (friction

Torque boost too high or too low (low speed)

Check:

Motor data

CP20 Encoder pulse number

CP21 Swap Encoder Channels

Mechanical load/issues (friction)

Loading...

Loading...