Hot Water Cleaner Batch 1015-1030

Kent high pressure\Hot Water 1015-1030\Brugs-Hedvand-EN-e.237.doc

The machine itself can withstand immersion in water, e.g. in a standard car wash, whereas electrical

components may only be cleaned using high pressure air and wiping with clean rags. Only clean whilst

the unit is cold.

Paint damage can be repaired by grinding and then applying layers of base coat and top coat

(1-component top coat).

Once the hot water cleaner has reached the end of its service life, it must be disposed of in accordance

with local authority scrappage regulations applicable at the time.

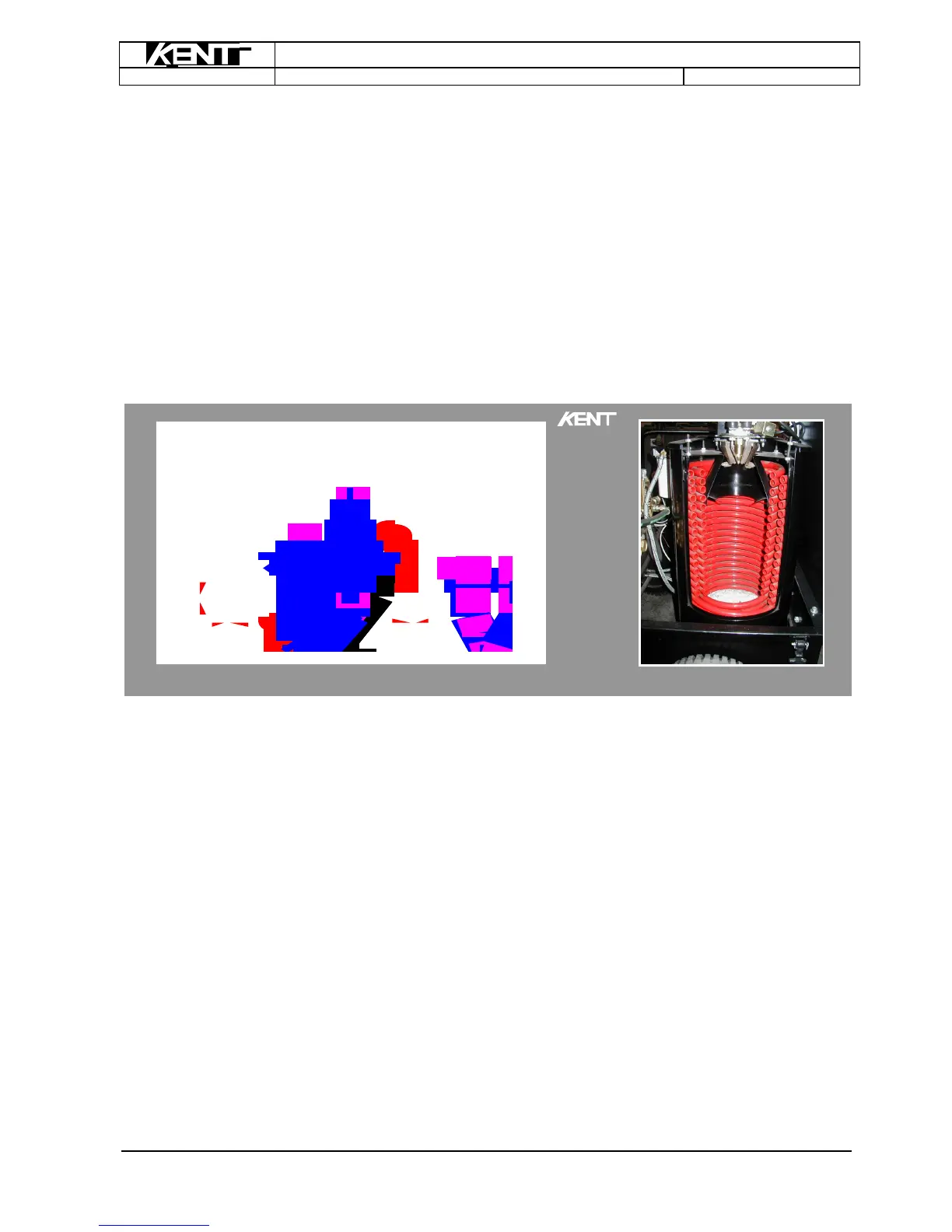

Combustion chamber:

The combustion chamber is to be inspected as necessary, or at least every 2 years, along with the

nozzle and check electrode.

The easiest way to clean the chamber is to insert a long brush and then vacuum out the loosened

debris. Finish cleaning by conducting OR test, which is to be carried out by an authorised technician.

Comply with national requirements, which may vary from country to country.

General:

Repeated fuse trips may be attributed to errors in the control system or electronic devices, and

incorrect current may cause electric shock. (230 Volts or 400 Volts)

Repairs may only be carried out by an authorised installer who is able to locate the fault and carry out

appropriate repairs before the hot water cleaner is put back into use.

Diesel nozzle:

The nozzle must be replaced as necessary, or at least every 2 years, following an inspection conduct-

ed by an authorised person. This is best done during an OR test and by an authorised technician.

Comply with national requirements.

Electrodes:

Clean electrodes are essential in order to achieve good operating economy and stable operation.

Therefore, we recommend that the electrodes are removed as necessary. or at least every 2 years,

during an inspection carried out by an authorised person. The entire starting assembly is located under

the top plate and, after a thorough cleaning (using a wire brush), check the following distances (see

drawing) before refitting. If the electrodes are burnt out, replace the entire starting assembly and, if

necessary, fit a new nozzle. This is best done during an OR test and by an authorised technician.

Loading...

Loading...