Hot Water Cleaner Batch 1015-1030

Kent high pressure\Hot Water 1015-1030\Brugs-Hedvand-EN-e.237.doc

4 Installation and fitting

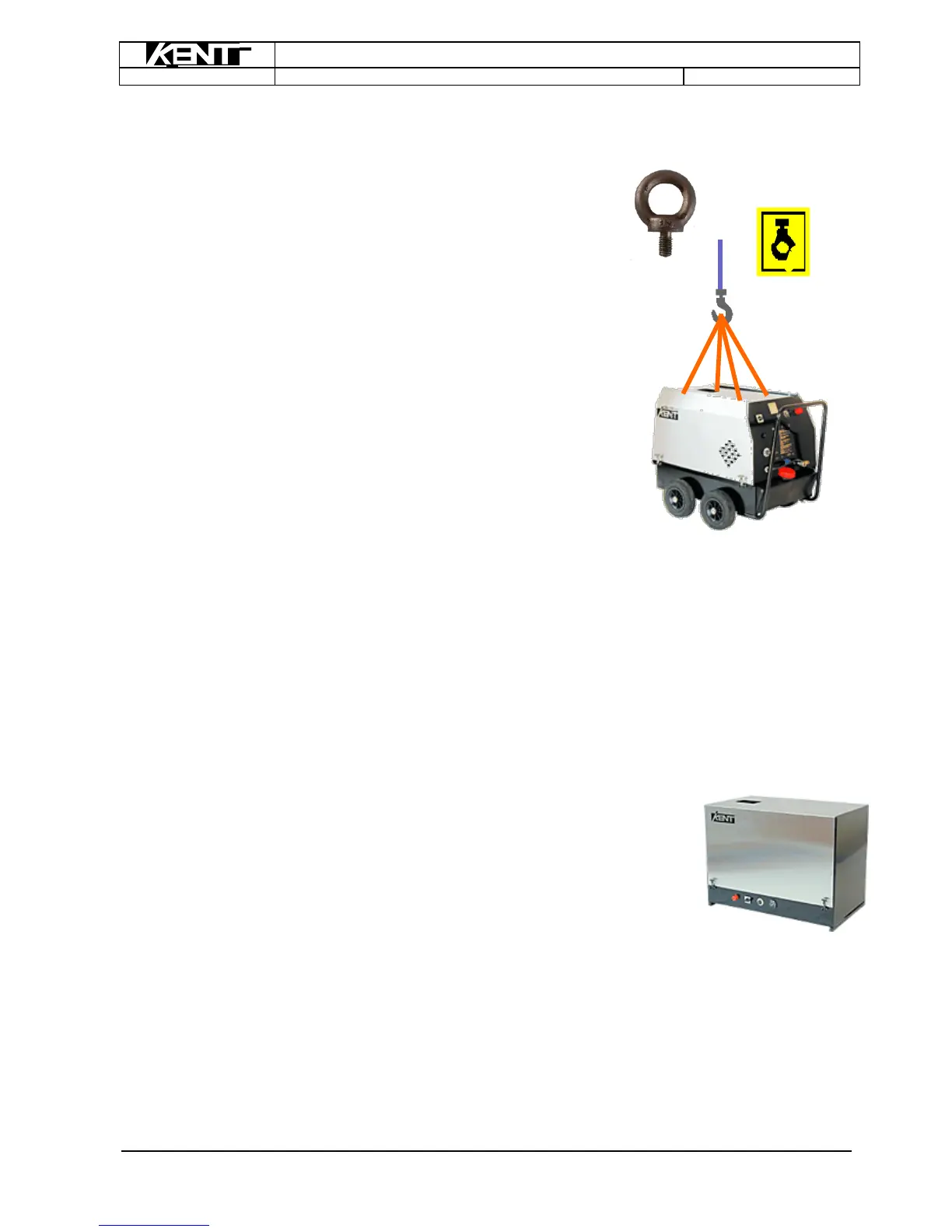

4.1 Moving

Crane lifts must be executed by securing the unit in 4 x M10 lifting

lugs with the original bolts in the top plate. Securing the unit in other

parts may result in accidents and is done at your own risk.

Lifting must be done with the power disconnected and the unit cold.

All accrued pressure in hoses and the boiler must be equalised.

Truck lift must only be executed across the machine and when the

unit is secured to a transport pallet.

Weight: approx. 135 - 190 kg without water. See data plate.

The unit may only be handled by individuals certified to conduct

manual handling of heavy loads. Never lift the unit above persons.

Avoid lifting the unit more than 0.5 metres. Make sure that the

transport route is free of people and other obstacles.

The machine must always be lowered with great caution. Bumps and impacts may affect the boiler’s

combustion chamber and glow plug, necessitating new settings to be applied in order to ensure reliable

and economical combustion.

The hot water cleaner has only been approved for use in industrial environments as its built-in compo-

nents do not satisfy the EMC requirements for use in residential areas.

4.2 Installation of stationary hot water cleaner

The only structural difference between the mobile and stationary model is the

cabinet. The unit is to be installed directly in the frame using bolts and screws. If

siting the unit in a free-standing position, 4 adjustable rubber feet must be used.

Stationary hot water cleaners shall be installed in areas where exhaust gas

emissions produce minimum inconvenience to the immediate environment.

In confined areas, exhaust gases must be routed to the open air through

appropriate piping. The installation must be carried out in accordance with

applicable regulations and building codes. In some countries, the installation

must also be approved by a local chimney sweep.

It is extremely important that the exhaust gases, or the pipe carrying such

gases, do/does not pass in close proximity to combustible materials or building

ventilation systems that may suck in dangerous carbon monoxide.

The electrical system of building installations shall be installed by a qualified

electrician.

Contact KENT if circumstances arise that may require expert help during

installation.

Loading...

Loading...