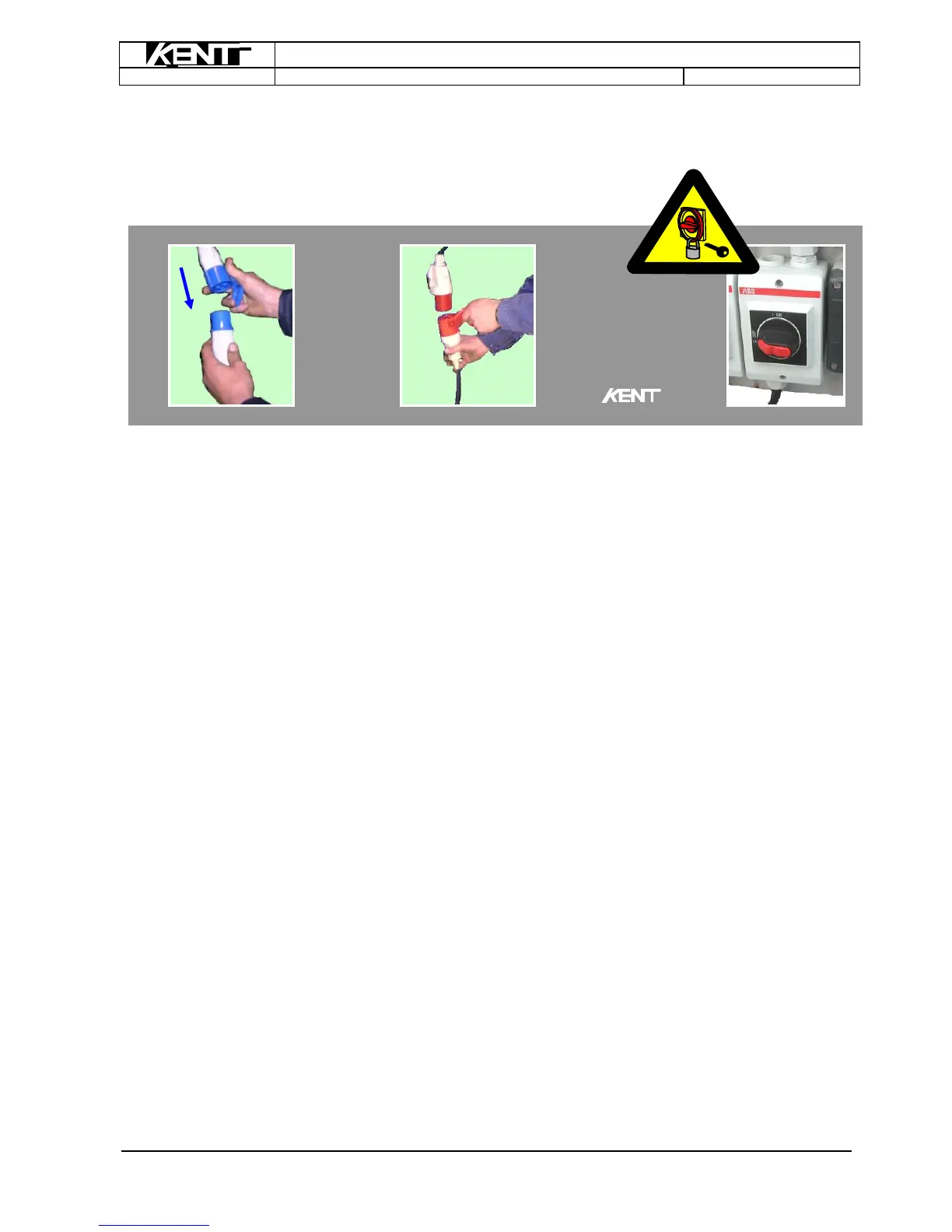

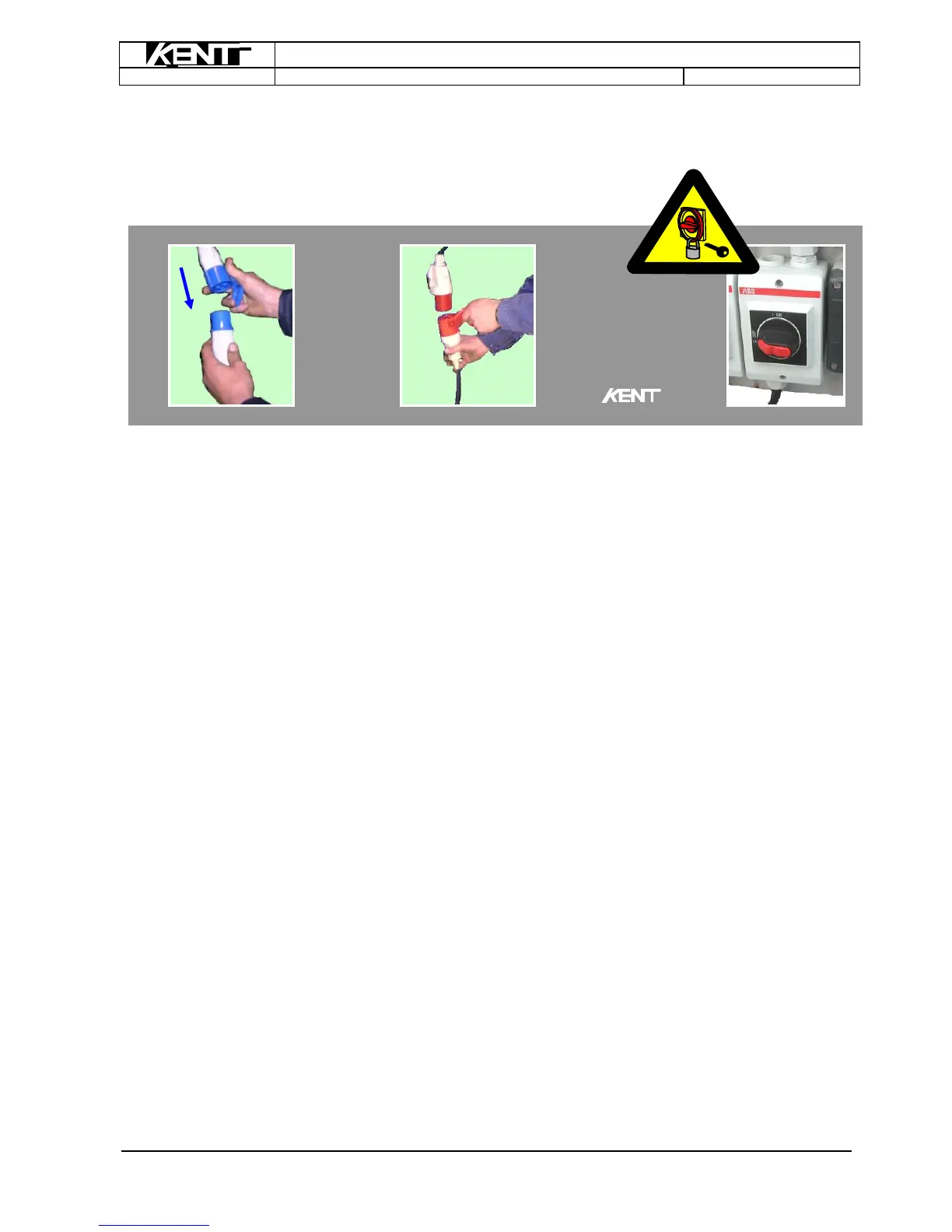

Any repairs or adjustments may only be carried out when the main switch is locked and when the hot

water cleaner is secured against accidental start-up. A removable power plug also provides an extra

layer of safety for the person conducting repairs.

Make sure that all pressure is equalised before disconnecting high pressure pipes and hoses.

During each start-up:

Conduct a visual check of the hoses for wear and tear.

Conduct a visual check for diesel leaks.

Conduct a visual check for a blocked exhaust.

Conduct a visual check for water leaks.

Monitor for thermostat stop.

Check for any noise from blow motor/motor bearings.

Once a year:

Perform a visual inspection of the chassis and lifting bracket. Look for cracks and loose bolts.

Test the thermostat by measuring the temperature. Heating must stop at 80° C.

Test flow meter.

Inspect exhaust pipes for signs of soot build up.

Thread collection by supply and discharge port.

Seals at all electrical installations.

Review of chassis for signs of rust and impact damage.

Evaluation of exhaust smoke - possible measurement of carbon ratio and CO2 level.

Apply a thin layer of lubrication to the wheel hubs if necessary.

Frost protection:

Drain the hot water cleaner by disconnecting the supply and discharge pipes, allowing the water to run

down the spiral pipe into the boiler. Tip the machine slightly in order to ensure that all the water runs

out.

Alternatively, coolant may be sucked into the pipe system through the cold water connection until the

fluid comes out of the nozzle on the spray gun.

Descaling:

Descaling is to be carried out as necessary and it is important in order to prevent clogging of the spiral

pipe in the boiler. Fill with water and acetic acid in a ratio of 1 part acetic acid to 10 parts water, and

allow to stand for a few hours. Flush out the loosened scale and dirt. In extremely hard water areas,

additional treatment may be necessary in order to avoid future clogging of spray gun nozzle.

Loading...

Loading...