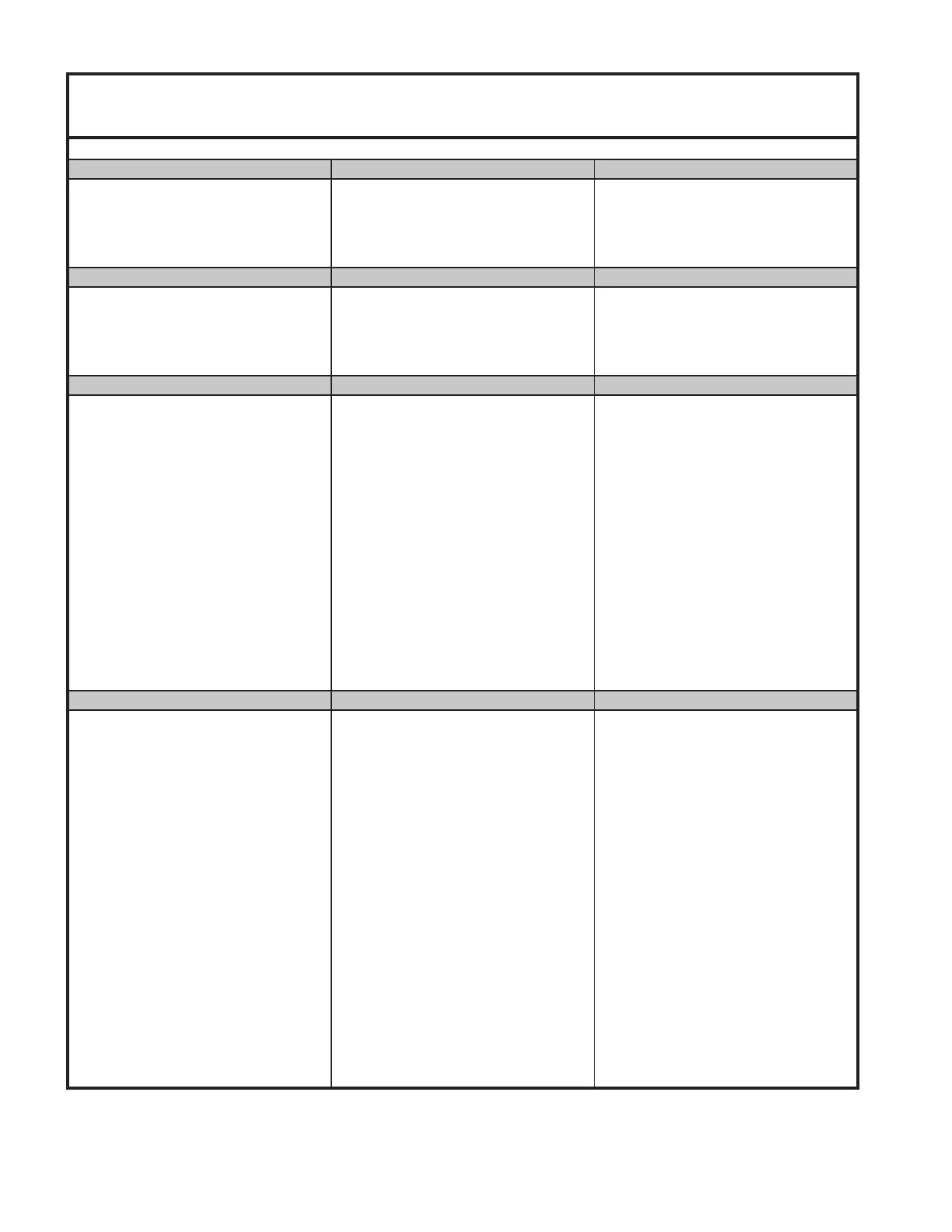

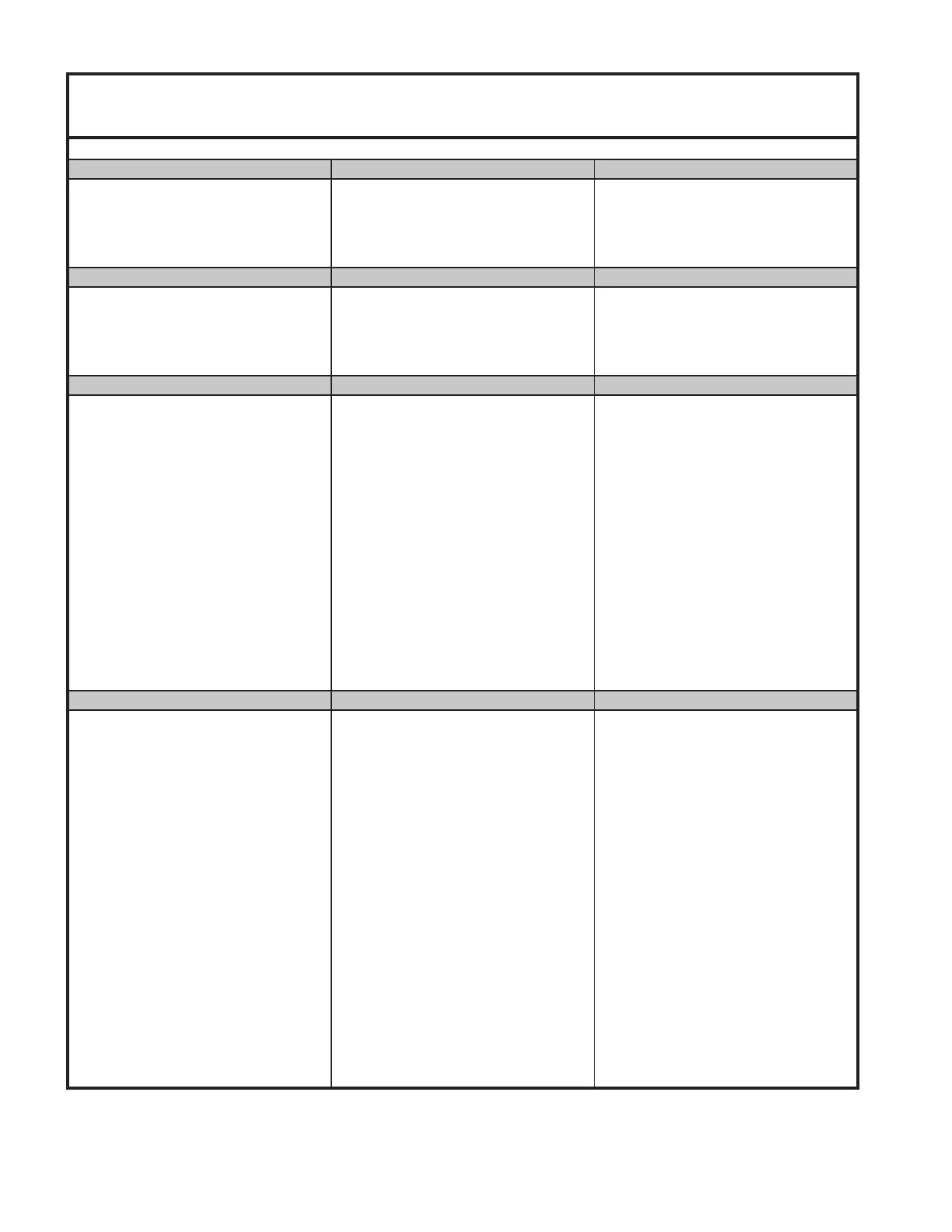

NOITULOSESUAC ELBISSOPMOTPMYS

Excessive Vacuum Motor noise. 1. Worn Vacuum Motor bearings

and / or fan blades.

1. Replace Vacuum Motor. (18007)

(See Repair Manual: Removing

Vacuum and Brush Assembly, and

Replacing Vacuum Motor.)

Burnt motor smell from clean air

exhaust.

1. Worn Vacuum Motor brushes.

NOTE: Excessive sparking may also

occur.

1. Replace Vacuum Motor (18007).

(See Repair Manual: Removing

Vacuum and Brush Assembly, and

Replacing Vacuum Motor.)

All switches are ON, ONLY Vacuum

Motor does not run.

1. Defective Vacuum Motor. 1. TEST: Test Vacuum Motor

(18007) using Vacuum / Brush Motor

Test Cable (7202) . If motor runs,

there is a problem with the electrical

system. NOTE: If motor does not

work, replace Vacuum Motor

(18007). (See Repair Manual:

Removing Vacuum and Brush

Assembly, and Replacing Vacuum

Motor.)

2. Defective Switch . 2. Replace Switch (10108) .

3. Terminals not connected or

defective.

3. Re-connect or replace Terminals .

Dirty liquid is being discharged

through the Vacuum Motor Exhaust

Tube (C4:10101 / C4-A: 10608).

1. The cleaning solution was not

poured from the Bucket into the

Solution Tank .

1. Pour the cleaning solution from the

Bucket into the Solution Tank .

NOTE: The solution is being sucked

into the Vacuum Motor

and then

blowing out the Exhaust Tube.

2. Foam is building up in the Bucket . 2. Empty Bucket without refilling the

Solution Tank . If available, add Anti

Foam to the emptied Bucket .

CLEAN UP Step 1: Sit the Bucket

aside. Move the machine to concrete

surface, such as the garage. Leave

the Lid up. Run the Vacuum Motor

only for 1 minute to blow out any

remaining liquid.

3. Too much liquid was added to the

Solution Tank .

3. Empty Bucket

without refilling the

Solution Tank . Do not exceed top Fill

Line of Bucket . Add less water to the

Solution Tank during next cleaning

cycle.

Step 2: Clean the discharged dirty

liquid from carpet immediately ! Spot

Remover or 7 in 1 may be needed.

ALSO: Using the Hand Tool may lift

spot better.

VACUUM SYSTEM CONTINUED

8

Loading...

Loading...