driven out of the solution and will

collect in high spots in the

system. These air bubbles can

interfere with pumping and

heat transfer and must be

eliminated.

Installation of air bleed valves at

the high spot(s) in the system

will allow for air elimination when

filling the system and will allow

re-venting in a day or so after all

air has been driven out of

solution.

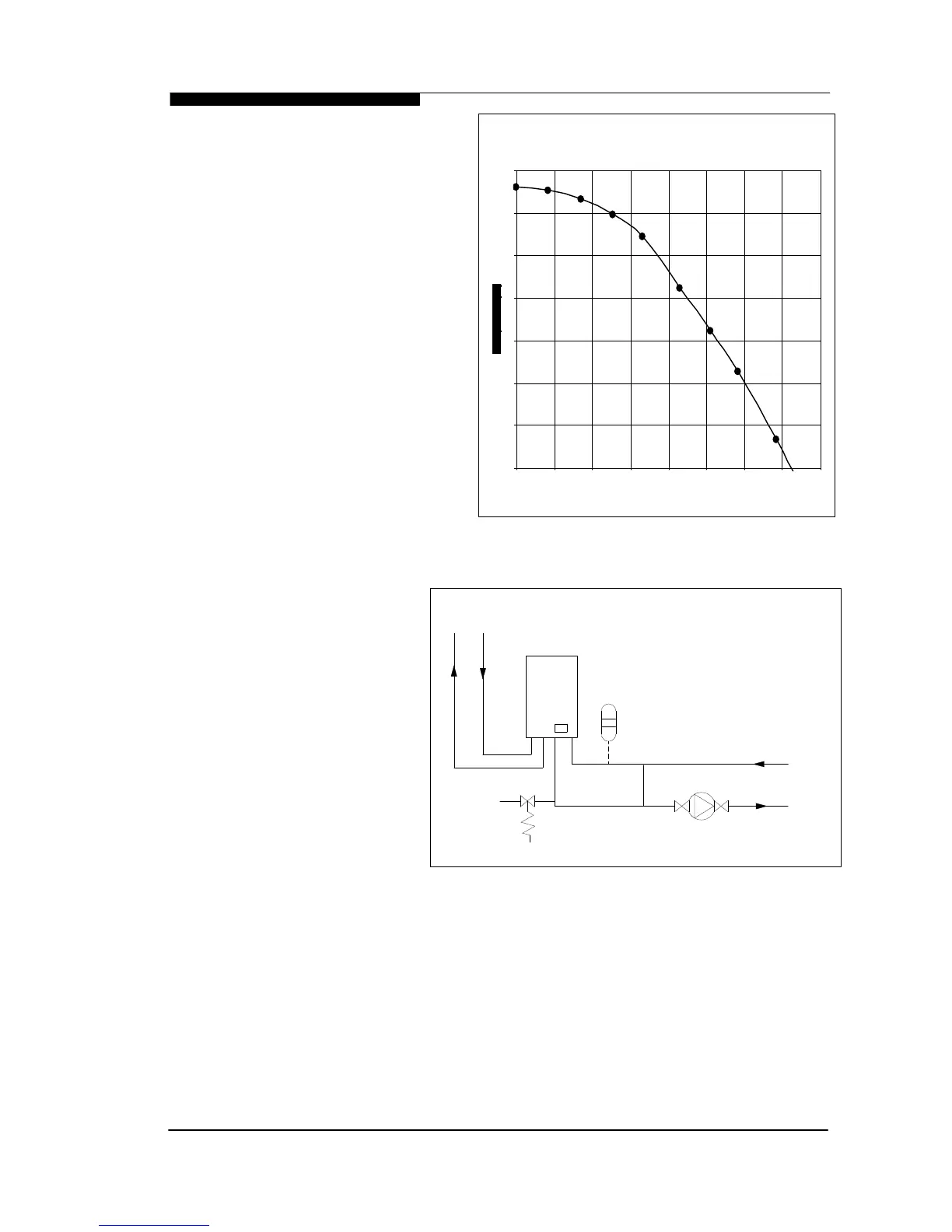

3.7.3 System Pump

Selection (if required)

The C36 Combi features an

integral circulating pump which

has sufficient excess head to

drive most domestic systems.

The available head is shown in

the graph below. If the system

index circuit resistance is in

excess of the available head

from the integral pump an

additional system pump will be

required.

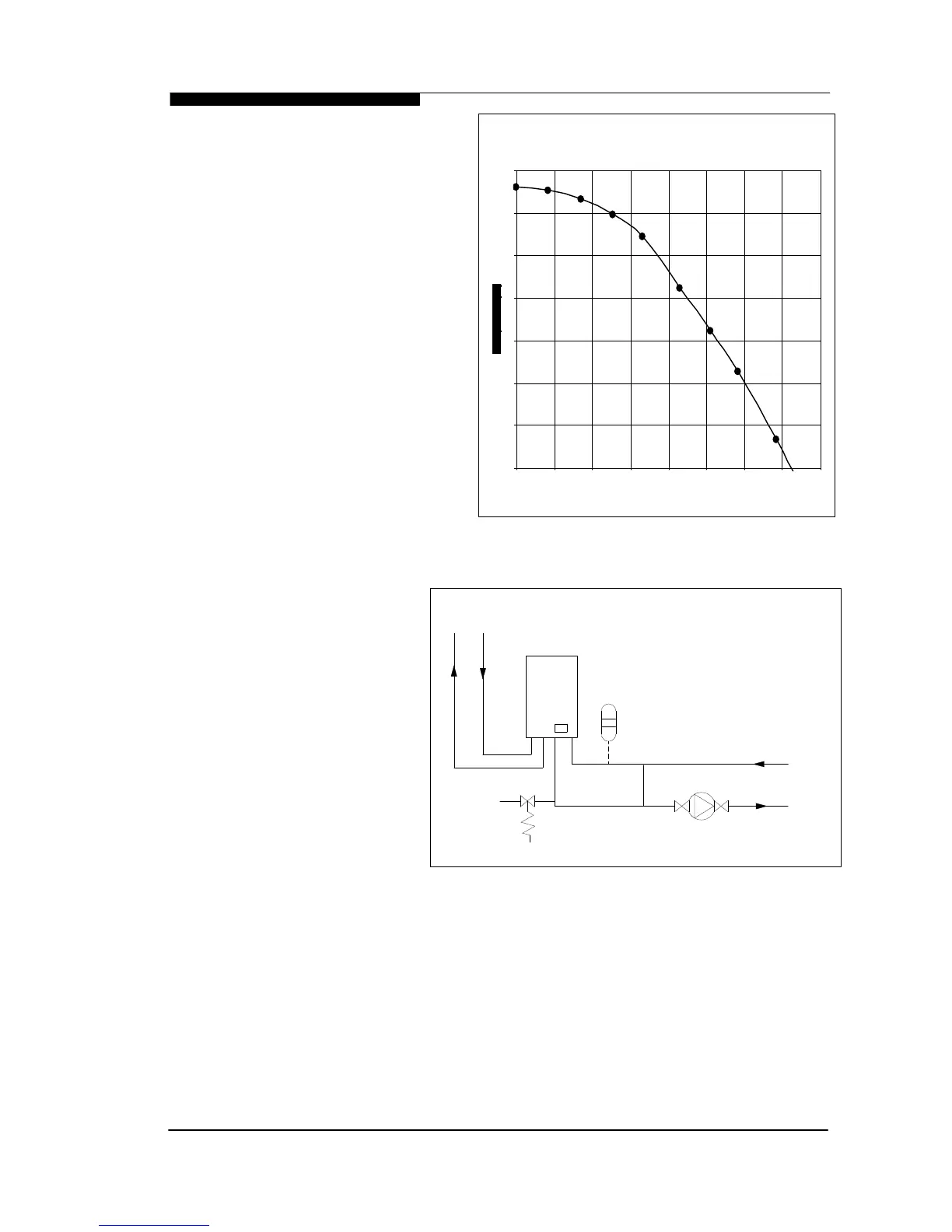

The schematic below

illustrates a

recommended approach

to using an additional

system pump. The

additional system pump

should be sized to

overcome the index

circuit resistance only as

the boilers integral pump

will overcome boiler

resistance.

If an additional pump is

required the selected

pump must comply with

BS 1394. Provision must

be made in the system

design for control of the additional pump.

3.7.4 Filling The System

The boiler is supplied with an approved filling loop device. This filling device is designed to

enable initial fill and topping up of system pressure. The system should be set to a

pressure of between 1.0 and 1.5 bar. To display the system water pressure press the

“Installer” button, on the boiler fascia, repeatedly until the number 5 appears on the

display. After a few seconds the display will change to show the water pressure, in bars.

Using the filling loop set the pressure to 1.0 to 1.5 bar,

WD388/0/2004 Chapter 3 - Boiler Location The Keston C36 & C36P Combi Boilers

Installation & Servicing Instructions Page : 14

Additional System

Pump

(if required)

COLD WATER SUPPLY

DOMESTIC HOT WATER

DOMESTIC WATER

(if required)

COMBI

HEATING CIRCUIT

KESTON

Expansion

Vessel

Drain

Cock

RETURN

FLOW

Permanently

Open 28mm

By-pass

C36 Combi Available pump head

0

1

2

3

4

5

6

7

0 5 1 0 1 5 20 25 30 35 40

Flow Rat e ( lpm)

Loading...

Loading...