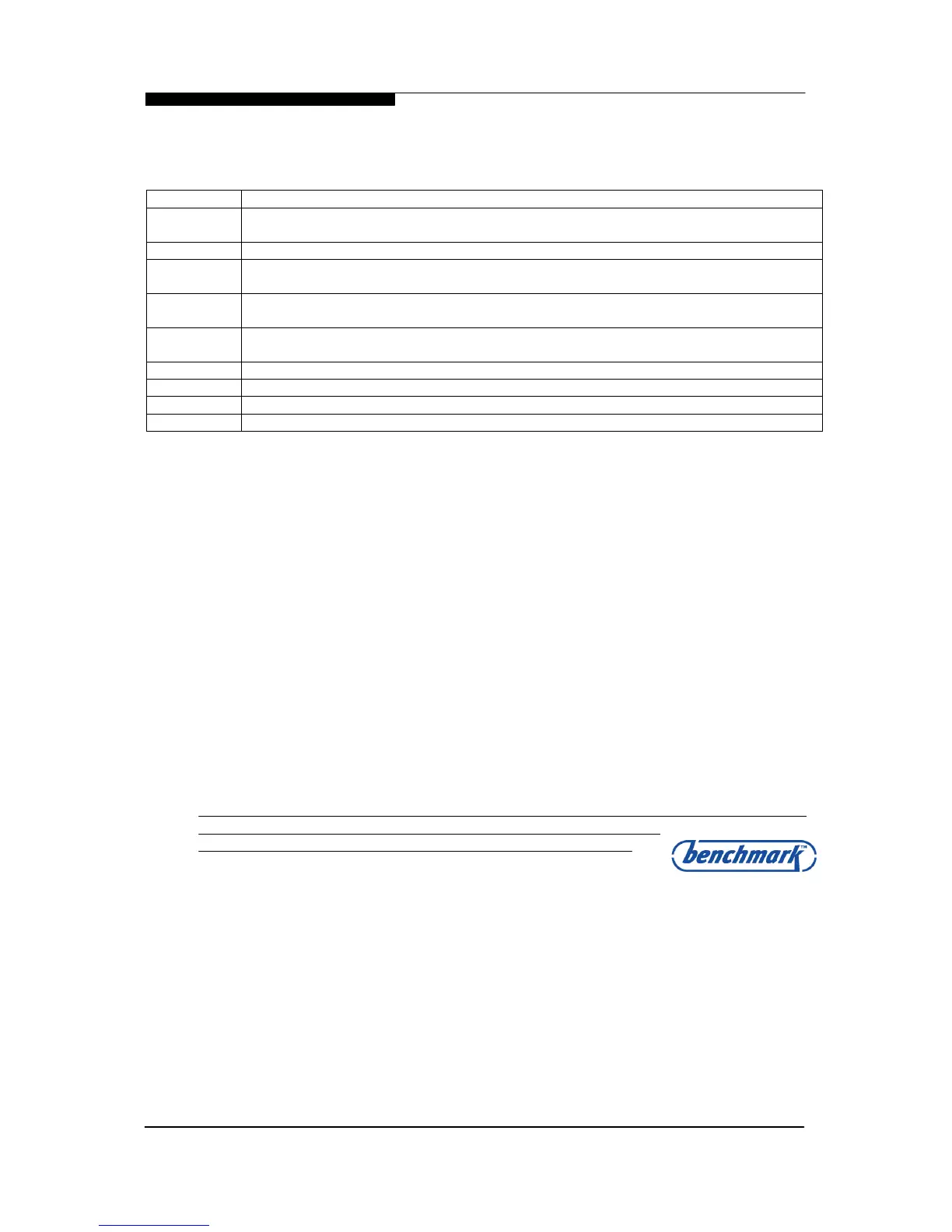

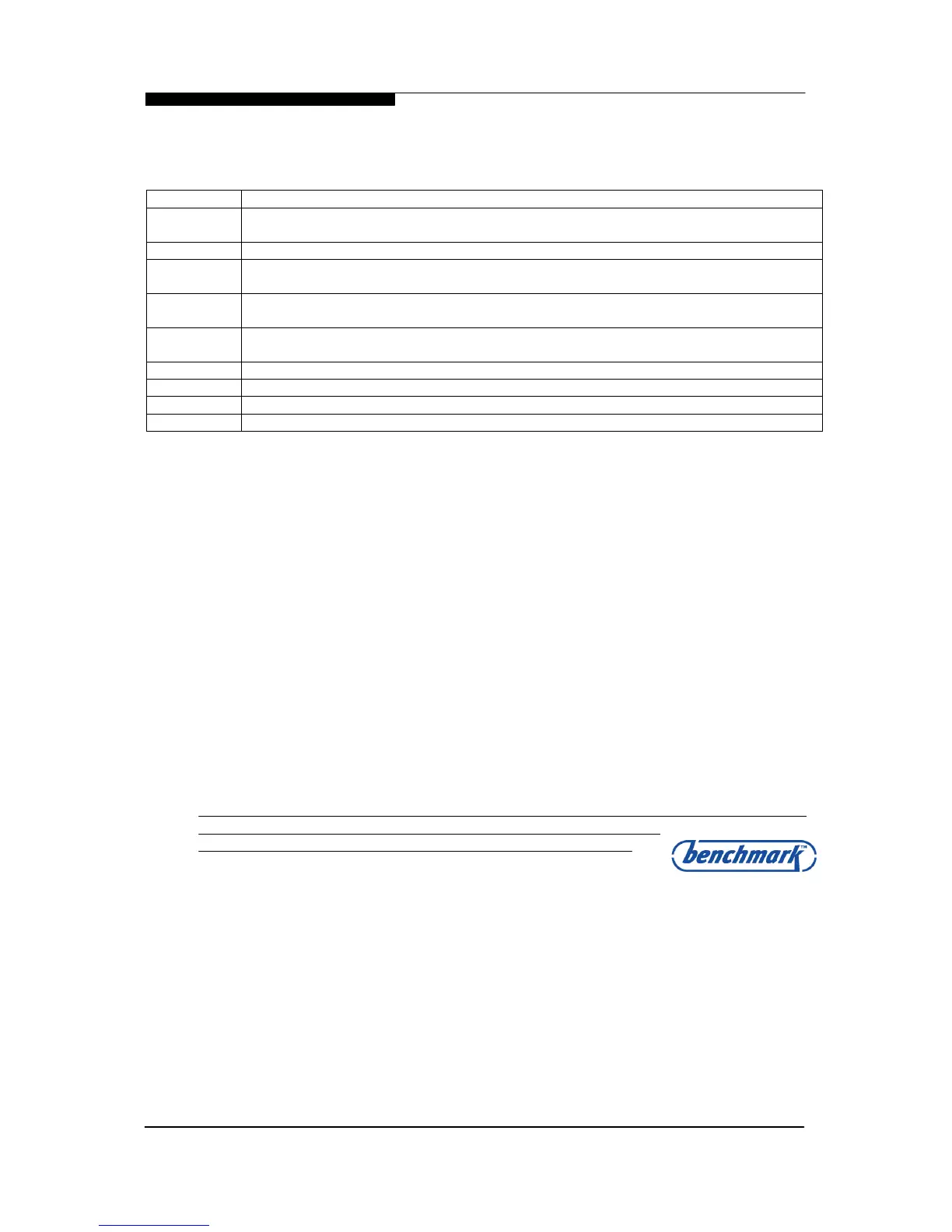

Fault Modes

In the event that the boiler detects a situation which it considers to be a fault the display will

change to show a flashing fault code starting with an “E” and then a two digit number. The

table below explains these codes and the action you should take.

Water pressure too high - You have put too much water pressure in your systemE40

Water pressure error - You must top up the water pressure for your systemE37

Mains supply frequency incorrect - There may be a problem with your power supply.E35

Mains supply voltage < 180V - There may be a problem with your power supplyE34

Flame drop out - Check for obstruction of the flue and/or air terminals,

blockage/freezing of the drain pipe or a low gas supply (LPG).

E26

Water pressure losses - You have topped up the water pressure more than 4 times in

24 hours. You may have a leak on the system..

E24

Boiler overheat - Check that any valves to the heating circuit have not been shut down,

that there is no air in the system and that the water pressure is correct..

E03

False flame - There is possibly a problem with the power supply.E02

Ignition failure - the boiler has attempted to light five times and not succeeded - check

the gas supply is on.

E01

Description of faultDisplay

The above is an abbreviate list of possible error codes. If the code is not in the list above

consult a GAS SAFE REGISTER registered engineer. A full list of codes can be found in

Chapter 6 of this manual. If a code appears and you feel the original cause has been rectified,

press the “Reset” button to resume boiler operation. If the code persists consult a GAS SAFE

REGISTER registered engineer.

When topping up the water pressure you can observe the actual pressure by pressing the

“Installer” button repeatedly until the number “5” appears. After a few seconds the display with

then change to show the system water pressure in bar. Set the water pressure to between 1.0

and 2.0 bar.

Precautions

Care must be taken at all times to ensure that no blockage or obstruction is present in the

condensate drainage line. In addition, the air intake and flue exhaust terminals must be free

from obstruction at all times.

Frost Protection

The C36 Combi has an integral frost protection function. However, care should also be taken

that any exposed pipework is adequately insulated to prevent freezing.

1.4 SAFETY INFORMATION

IF YOU SUSPECT A GAS LEAK TURN OFF THE APPLIANCE IMMEDIATELY, TURN OFF

THE GAS TAP TO THE APPLIANCE (LOCATED UNDERNEATH)

AND CONTACT YOUR LOCAL GAS REGION WITHOUT DELAY.

Benchmark Initiative

As part of the industry wide “Benchmark” initiative C36 Combi boiler manual includes Gas

Boiler Commissioning Checklist (Chapter 10). This form should be completed by your

installer at the end of the installation and commissioning process. The details of the Checklist

will be required in the event of any warranty work being required. There is also Service

Interval Record (Chapter 10) to be completed after each annual service visit.

These forms (Chapter 10) should be kept in a safe place for the life of the boiler.

The boiler should be installed and serviced only by GAS SAFE REGISTER registered

operatives. All GAS SAFE REGISTER registered Installers carry a GAS SAFE REGISTER ID

card and have a registration number. Both should be recorded in your boiler manual

(Chapter 10: GAS BOILER COMMISSIONING CHECKLIST). You can check your installer by

calling GAS SAFE REGISTER direct on 0800 408 5500.

WD388/0/2004 Chapter 1 : User Instructions The Keston C36 Combi & C36P Combi Boilers

Loading...

Loading...