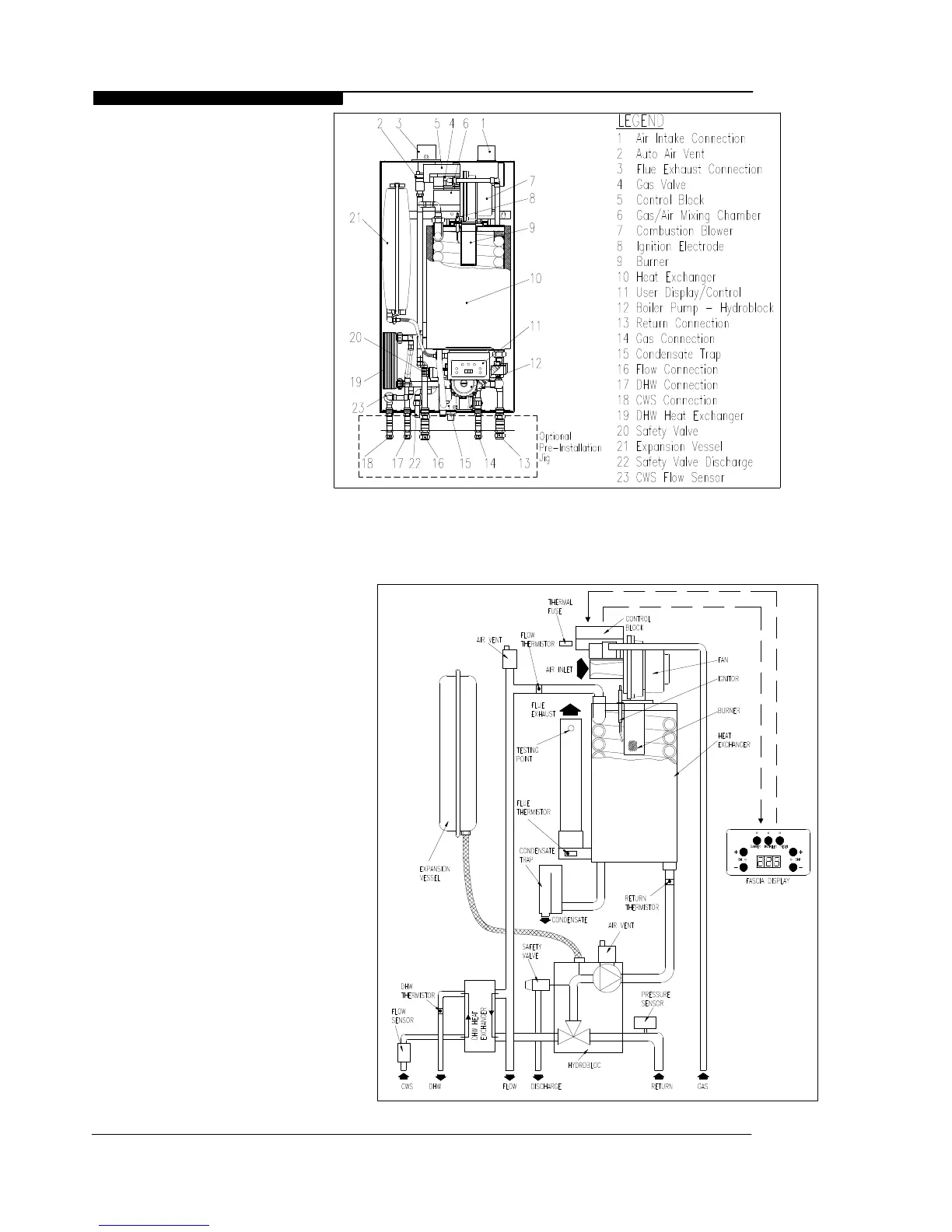

system and burns with

a blue flame just off

the surface of the

burner. As the hot

products of

combustion pass

downwards, they are

cooled by exchanging

heat with the

circulating water which

enters the heat

exchanger at the

bottom of the heat

exchanger. The

optimum heat input is

detected by monitoring

flow and return

temperatures and is

adjusted by controlling

the speed of the fan.

The optimum pump

speed is also detected

and automatically

selected by the boiler.

When the return water temperature is below 55

o

C, part of the water vapour in the

combustion products will condense inside the heat exchanger, thus increasing the boiler

efficiency further by releasing

the latent heat of

condensation. This

condensate falls to the

bottom of the heat exchanger

where it is separated from

the flue gases and exits from

the boiler through the

condensate drain. Any

condensate formed in the

flue runs back down the

flueway and is drained at the

base of the flue connection

to the heat exchanger or

drain points within the flue.

The condensate is very

slightly acidic (about the

same acidity as vinegar) and

should be piped in a plastic

pipe. It is not harmful to the

waste disposal system and

may be disposed of as

normal waste water.

The flue gases are piped in a

50 mm muPVC (BS5255

and/or BSEN1566-1 and

BSEN1329) plastic or,

alternatively, 75mm Keston

composite plastic pipe to

outside. The temperature of

the flue gases are usually

WD388/0/2004 Chapter 2 : General Instruction The Keston C36 Combi & C36P Combi

Boilers

Installation & Servicing Instructions Page : 4

Loading...

Loading...