2

1. Introduction (2)

1-4 Specications

Type

Distance setting

Appearance

M18 Threaded Mount

Model

LR-ZH490CB

*1

Detectable distance

25 to 490 mm (465 to 0)

*2

Standard detection deviation

25 to 170 mm : 9 mm

170 to 290mm : 25mm

290 to 390mm : 40mm

390 to 490mm : 50mm

Display resolution

1 to 5 (1 to 5 mm)

Spot diameter

Approx. φ3 mm

Response time

1.5 ms/10 ms/50 ms selectable

Light source

Type

Red laser (660 nm)

Laser class

Class 2 laser product (IEC60825-1)

Class

Laser product (FDA(CDRH) Part1040.10)

Function

Indicator

3-digit 7-segment display (white),

output indicator (yellow),

DATUM indicator (orange), 1 spot indicator (green)

Timer

OFF/ON delay/OFF delay/One-shot

Specications

Power voltage

10 to 30 VDC, including 10% ripple (P-P), Class 2 or LPS

Power

consumption

450 mW or less

(18 mA or less at 24 V, 34 mA or less at 12 V)

Control output

NPN open collector/PNP open collector selectable,

Applied voltage 30 VDC or less,

Control current 100 mA or less,

Residual voltage 1.2 V or less at 10 mA or less,

2 V or less at 10 to 100 mA

Protection

circuit

Protection against reverse power connection,

output overcurrent, output surge,

reverse output connection

Output

operation

Light-ON/Dark-ON selectable

External input

Short-circuit current NPN: 1 mA or less/

PNP: 2 mA or less

For input time, refer to the time chart.

(Instruction manual page 5)

Environmental

resistance

Enclosure

rating

IP68(IEC60529)/IP69K(DIN40050-9)/

4X, 6P, 13(NEMA250)

Ambient light

*3

Incandescent lamp: 10,000 lx or less

Sunlight: 20,000 lx or less

at 240 mm

Incandescent lamp: 2,000 lx or less

Sunlight: 4,000 lx or less

at 490 mm

Ambient

temperature

−10 to +50°C (no freezing)

Storage

temperature

−25 to +75°C (no freezing)

Ambient

humidity

35 to 85%RH (no condensation)

Shock

resistance

1,000 m/s

2

in X, Y, Z axis directions respectively 6 times

Vibration

resistance

10 to 55 Hz Double amplitude 1.5 mm in the X, Y, Z

axis directions respectively, 2 hours

Insulating

resistance

20 MΩ or more (500 VDC)

Withstand

voltage

1,000 VAC 50/60 Hz 1 min

Material

Case: SUS316L, Display: PES,

Lens cover: PMMA with scratch-resistant coating,

Packing/Connector ring: FKM

Nut: SUS316L, Toothed washer: SUS304

Weight

Approx. 75 g

*1 IO-Link specication v.1.1/COM2 (38.4 kbps) is supported. (Only when PNP output is

selected.)

You can download a setup le from the KEYENCE website (http://www.keyence.com).

If you are using the product in an environment in which you cannot download les over

the Internet, contact your nearest KEYENCE ofce.

*2 Display reading used as a guide for the detecting distance. When the setting value is

tuned, the readout shifts. When the value exceeds “-99”, “-FF” is displayed.

*3 When the response time is 10 ms

1-5 Package contents

• Sensor

A connector cap is supplied with connector sensors.

• FDA warning/certication/identication label

• Laser warning/explanation labels

• Instruction Manual

• Nut

• Toothed washer

2. Installation and Wiring

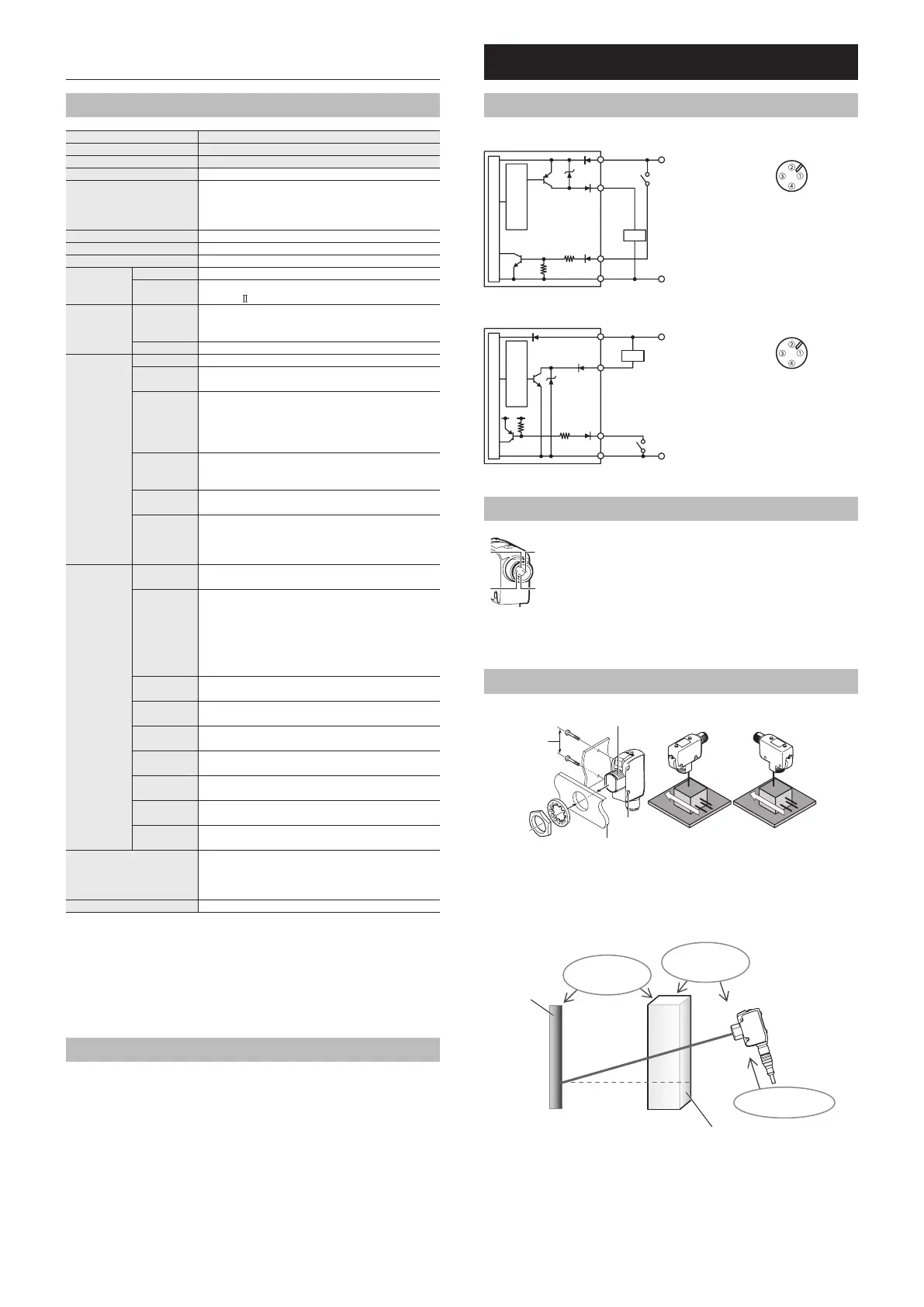

2-1 I/O Circuit Diagram

z When PNP output is selected

Overcurrent

protection circuit

Brown/1

White/2

10 to 30 VDC

0 V

Black/4

Blue/3

Load

Sensor main circuit

M12 connector (4-pin) type

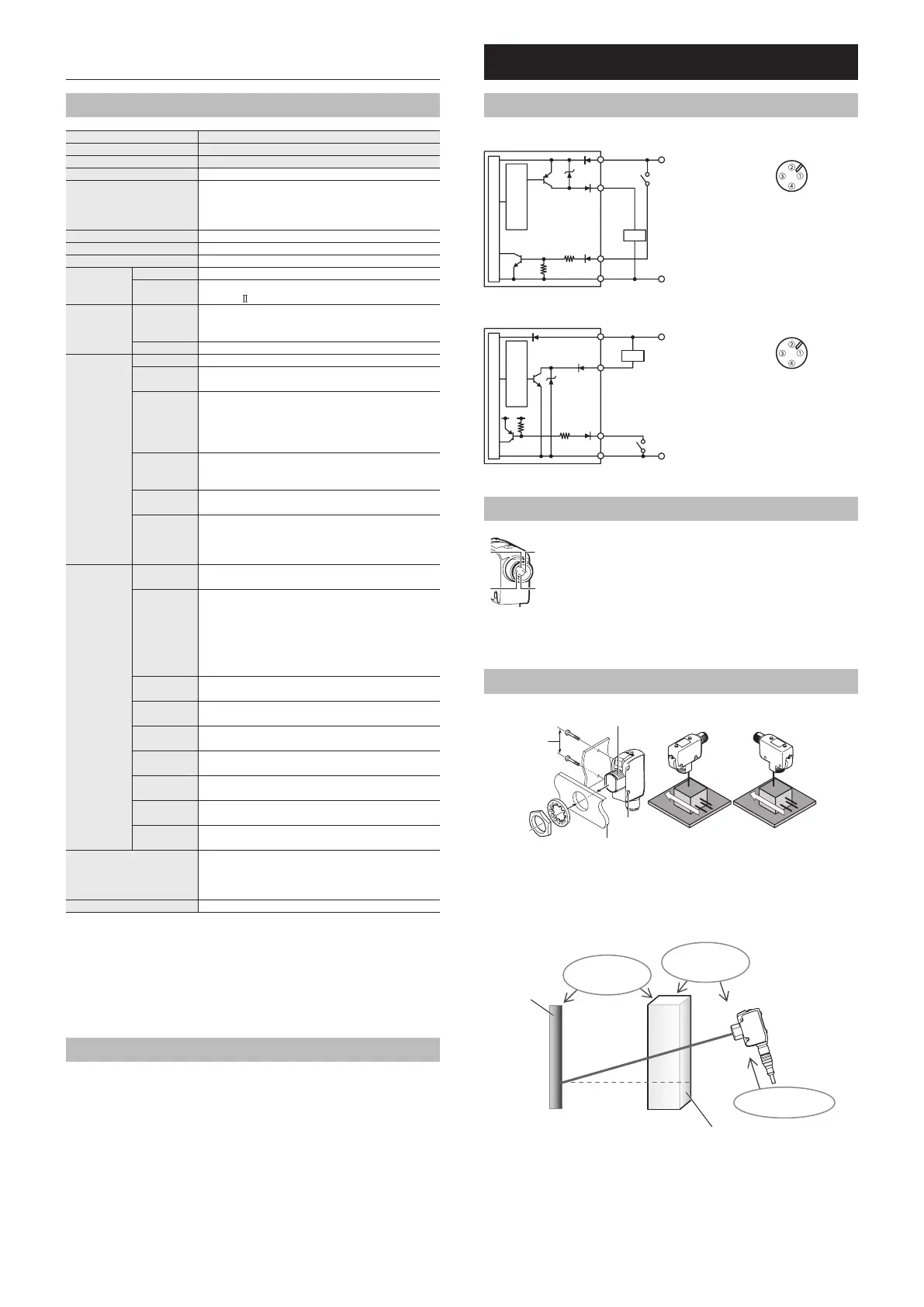

z When NPN output is selected

Brown/1

Black/4

10 to 30 VDC

0 V

White/2

Blue/3

PLC, etc.

3 VDC

Overcurrent

protection circuit

Sensor main circuit

Load

M12 connector (4-pin) type

2-2 Wiring

1 : 10 to 30 V

2 : OUT (NPN)/IN (PNP)

3 : 0 V

4 : OUT (PNP)/IN (NPN)

M12 Connector tightening torque: 0.8 Nm

* Tighten the connector by a hand, and then retighten it by using tools and so on.

Insufcient tightening will degrade water-resistant performance.

2-3 Installation

24.1 mm

Tightening

torque: 0.6 Nm

or less

M18 Tightening torque:

20 Nm or less

Direction of installation

3 mm or less

φ3.2

OK NG

If detection is unstable

• When detecting transparent targets, move the sensor as close as possible to the

workpiece, and move the workpiece as far away as possible from the background for

increased stability.

• Tilt the optical axis of the sensor as much as possible in reference to the background

surface. (10° or more)

Reference

surface

Separate as far

apart as possible.

Move as close

as possible.

Tilt the beam axis

downward.

Transparent object

• For thin objects or transparent objects, use of “Universal Change Detection” is

recommended. (See “ Universal Change Detection” (page 3))

• If the sensor is affected by ambient light, install a light blocking plate, or change the

installation location.

Loading...

Loading...