Get more information

• Consideration for instrument grounding

5989-9200ENA

• Bench instrument site check table 5989-

4992ENA

• Do STEP daily ESD self-check 5989-

5752ENA

• EOS/ESD limiter N9355CK01

Protect the input and output

connectors

• Avoid repeated bending of cables; a single

sharp bend can damage a cable instantly and

permanently.

• Limit the number of connections and

disconnections to reduce wear.

• Inspect the connectors prior to use; look for

dirt, nicks, and other signs of damage or

wear. A bad connector can ruin the good

connector instantly.

• Clean dirty connectors to prevent poor

electrical connections and avoid damage to

the connector.

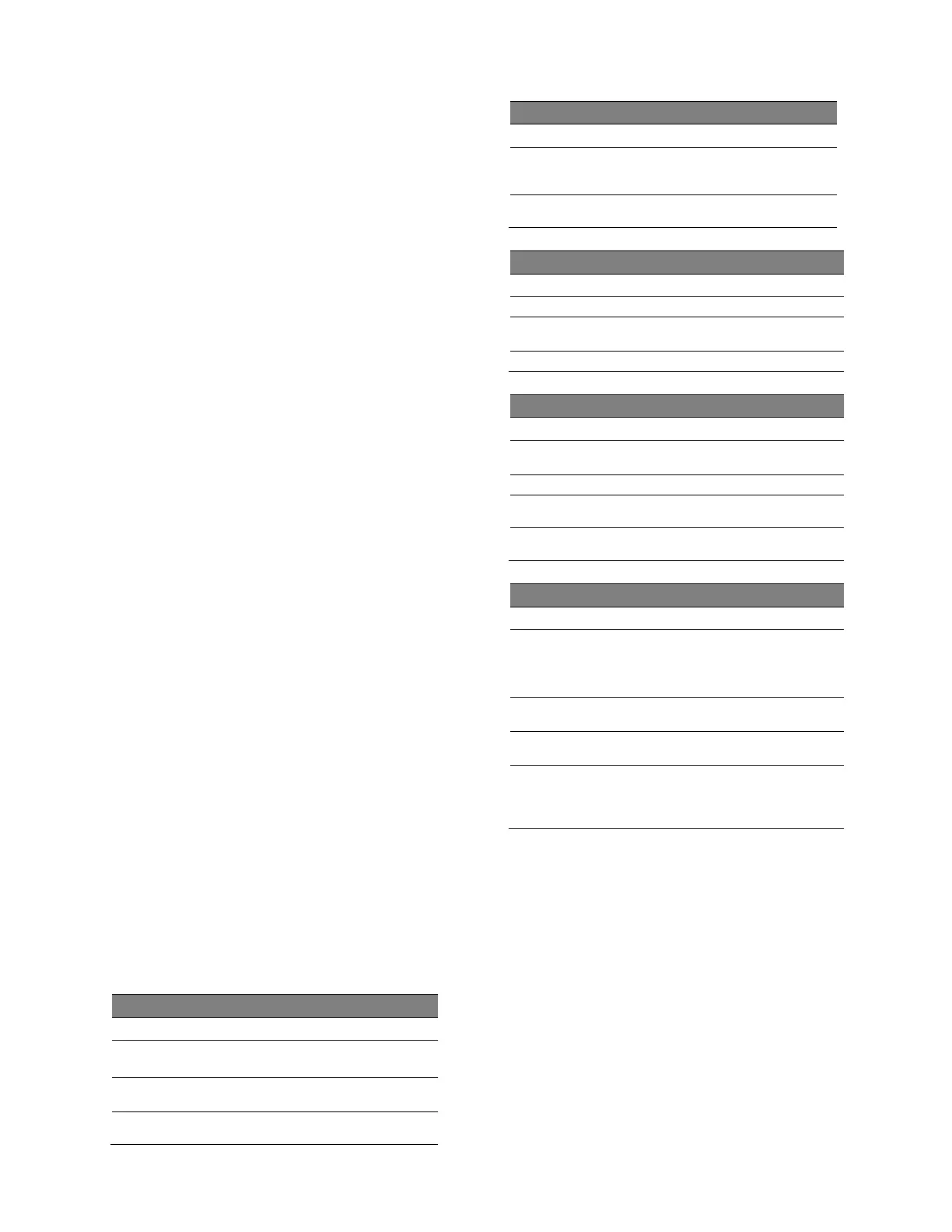

Use proper connector care and

connection techniques

• Proper connector care and connection

techniques are critical for accurate,

repeatable measurements, and for extending

the life of your devices.

• Prior to making connections, be sure to read

all of the connector care information

provided with your product.

• While connecting a module which requires

the sync cable connection (e.g. M8062A,

M8051A) to the test setup, make sure to

connect the sync cable after completing the

other connections. Also, remove the sync

cable first while disconnecting the

connections.

• Follow the connector care and connection

techniques listed in the following tables.

Handling and Storage

• Keep connectors clean • Touch mating-plane

surfaces

• Extend sleeve or connector

nut

contact-end down

• Use plastic end caps

Visual Inspection

• Inspect all connectors

carefully before every

Use a damaged

connecter - ever

• Look for metal particles,

Connector Cleaning

• Try compressed air first

• Use isopropyl alcohol

Get liquid into plastic

support beads

• Clean connector threads

Gauging Connectors

• Clean and zero the gauge

before use

connector

• Use the correct gauge type

• Use correct end of

• Gauge all connectors

Making Connections

• Align connectors carefully

connection

• Over tighten preliminary

connection

• Turn only the connector

nut

connection

• Use a torque wrench for

final connect

wrench "break" point

• Support attached cables

on bench or other surface

unsupported (cable

weight places strain on

connectors)

Protect the RF connectors

• Be careful not to bend, bump or flex any

device under test (DUT) connected to

instrument (such as filters, attenuators, or

large cables). This will reduce the amount of

strain placed on the connectors and the

mounting hardware.

• Ensure externally connected items are

properly supported (not freely suspended)

from the connectors.

• Always use torque wrench and gauge tools

for connecting RF connectors.

• Do not mix 50 and 75 Ω connectors and

cables.

Loading...

Loading...