8

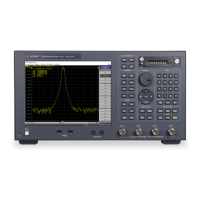

About the EMI Receiver Measurement Application

The Role of Precompliance in the Product Development Cycle

The Role of Precompliance in the Product Development Cycle

To ensure successful electromagnetic interference (EMI) compliance testing,

precompliance testing has been added to the development cycle. In precompliance

testing, the electromagnetic compatibility (EMC) performance is evaluated from

design through production units.

It is important to have a strategy that will help you test for potential EMI problems

throughout the product development cycle. It is also important to have equipment

and processes in place that will allow you to observe how close you are to

compliance at any given time in the development cycle. This reduces the time and

cost associated with final compliance testing.

Compliance Measurements

Electrical or electronic equipment that uses the public power grid or has the potential

for electromagnetic emissions must pass EMC (electromagnetic compatibility)

requirements. These requirements fall into four broad types of testing:

• Conducted emissions testing focuses on signals present on the AC mains that are

generated by the device under test (DUT). The frequency range of these

measurements is typically 9 kHz to 30 MHz. However, MIL-STD measurement

may have a wider frequency range.

• Radiated emissions testing searches for signals being emitted from the DUT

through space. The typical frequency range for these measurements is 30 MHz to

1 GHz or 6 GHz, although FCC regulations require testing up to 40 GHz.

• Radiated immunity is the ability of a device or product to withstand radiated

electromagnetic fields.

• Conducted immunity is the ability of a device or product to withstand electrical

disturbances on power or data lines.

Loading...

Loading...