44

V. MAINTENANCE AND CARE

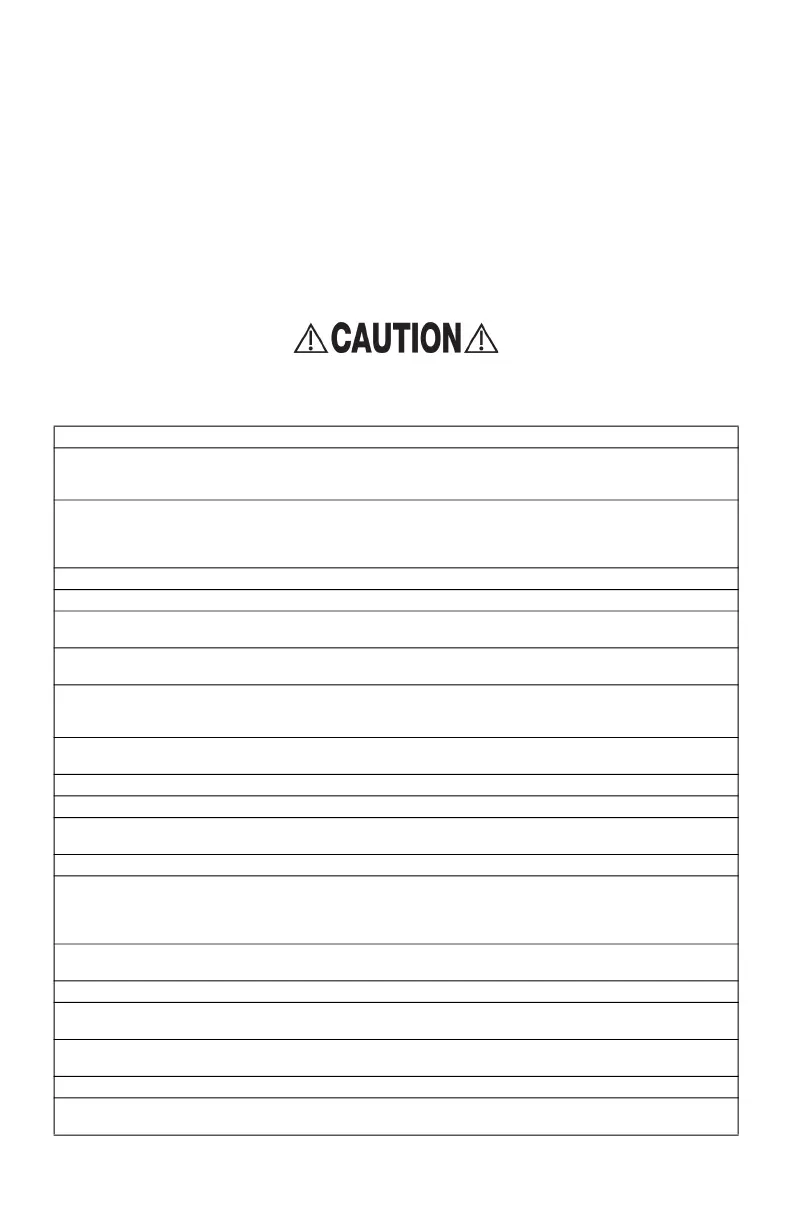

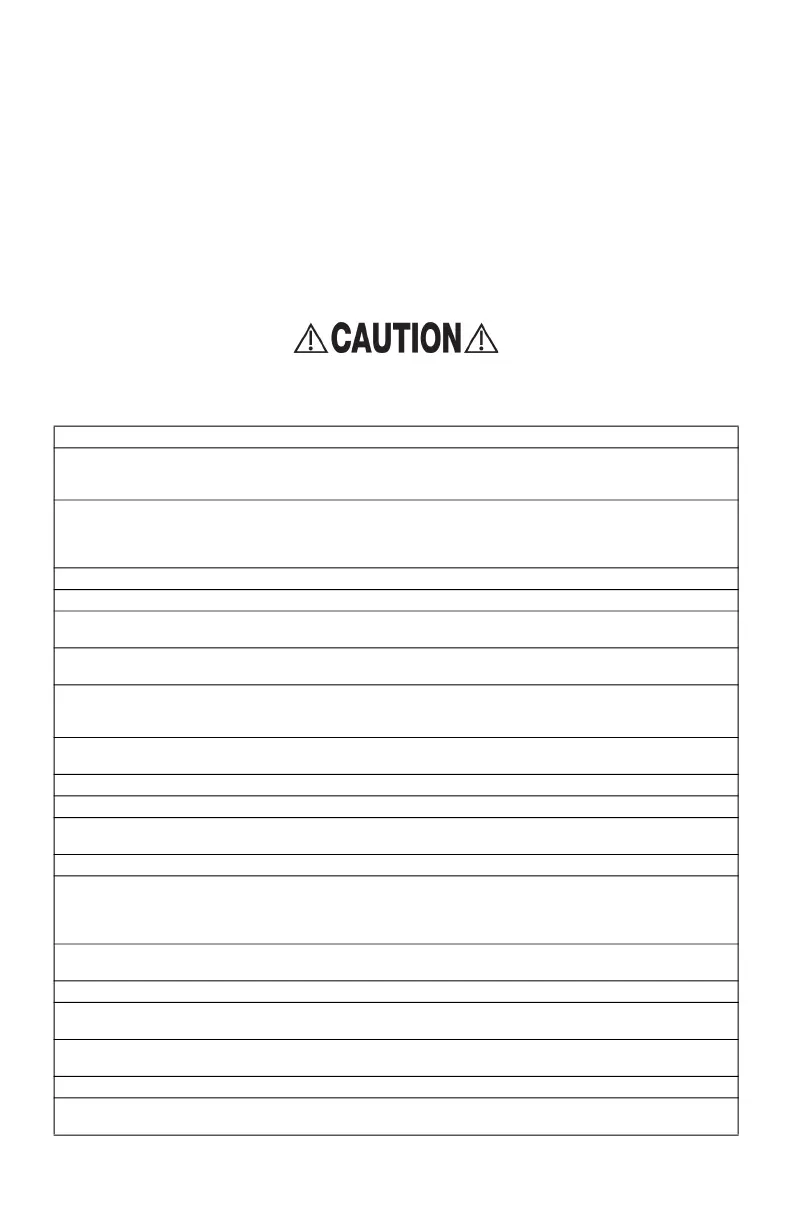

A. Maintenance Table

Regular and routine maintenance will extend the life of your wheelchair while improving its

performance. Wheelchair repairs, the replacement of parts and any maintenance check that you

are not comfortable performing should be done by an authorized supplier. Only use Ki Mobility

approved parts when replacing components. Contact your Authorized Service Representative

(Dealer locator can be found at Ki Mobility website) for parts information, identification, ordering

and additional technical information or instruction. Most components are illustrated in "Ki Parts"

on the Ki Mobility website.

Common tools to perform user authorized maintenance include: Tire pressure gauge, open end

metric wrenches and metric allen wrenches.

CAUTION: Do not use petroleum-based solvents, degreasers or dewatering agents (includ-

ing but not limited to automotive cleaners, alcohols or WD-40). Damage to components,

bearings or finishes may occur.

Check Weekly Monthly Annually

Check the tire inflation levels and inflate as needed. The correct inflation

levels are found on the tire.

(See pressure conversion table below if required -

Fig. 34)

√

Check wheel lock engagement and disengagement. Tire pressure changes

and tire wear will require the wheel locks to be adjusted. Wheel lock

adjustment instructions can be found in the Wheel Locks section of this

manual.

√

Check the axle sleeves to ensure the axle sleeve nuts are tight. √

Check that quick release axles engage and disengage properly. √

Check that caster wheels, anti-tip wheels and rear wheels spin freely.

Cleaning or replacement parts may be needed if there are any issues.

√

Clean area around the caster housing and bearings. This is a common

location for hair build up.

√

Clean your wheelchair. In the event of corrosive spills or exposure to

biohazards, remove contaminants immediately. See the Cleaning section in

this manual for instructions.

√

Check the rear tires, anti-tip wheels and the caster wheels for wear spots or

damage. Replace immediately if needed.

√

Check handrims to ensure they are secure and not damaged. √

Check that the hand grips do not rotate or pull off. Replace if needed. √

Check armrest receivers for loose or missing fasteners and check they are

secure, adjusted properly and maintain position.

√

Check that anti-tips are level and functional. √

Inspect the frame(s) and anti-tips for deformities, defects, cracks, dimples

or bends. These could be signs of fatigue in the wheelchair which could

result in a failure. Discontinue use of the wheelchair immediately and

contact an authorized supplier.

√

Check upholstery for signs of wear, fraying or holes. Replace upholstery

immediately if needed.

√

Check arm pads, cushions and back rest for damage, rips or tears. √

Check wheels for any loose, broke or bent spokes. Replace immediately if

needed.

√

Check that all fasteners are tight. Unless otherwise noted, fasteners should

be tightened to 40 in./lbs (4.51 N*m).

√

Verify the wheelchair rolls easily and straight. √

Have the wheelchair checked and adjusted by a qualified technician at your

authorized supplier.

√

Loading...

Loading...