4

BUILDING YOUR ENCLOSURE

The actual construction of the enclosure is fairly simple, but some rules must be fol-

lowed to make sure your cabinet is solid and airtight:

Use very sturdy wood, such as 3/4" MDF (medium density fiberboard) or multi-ply marine

plywood. Avoid low density material such as common particle board and low grades of ply-

wood.

Join the edges with a high quality wood glue. Do not use silicone, hot glue or caulking

materials to connect two pieces of wood.

Use drywall screws or a pneumatic staple gun to hold it together while the glue dries. A

screw or staple every 3" will suffice.

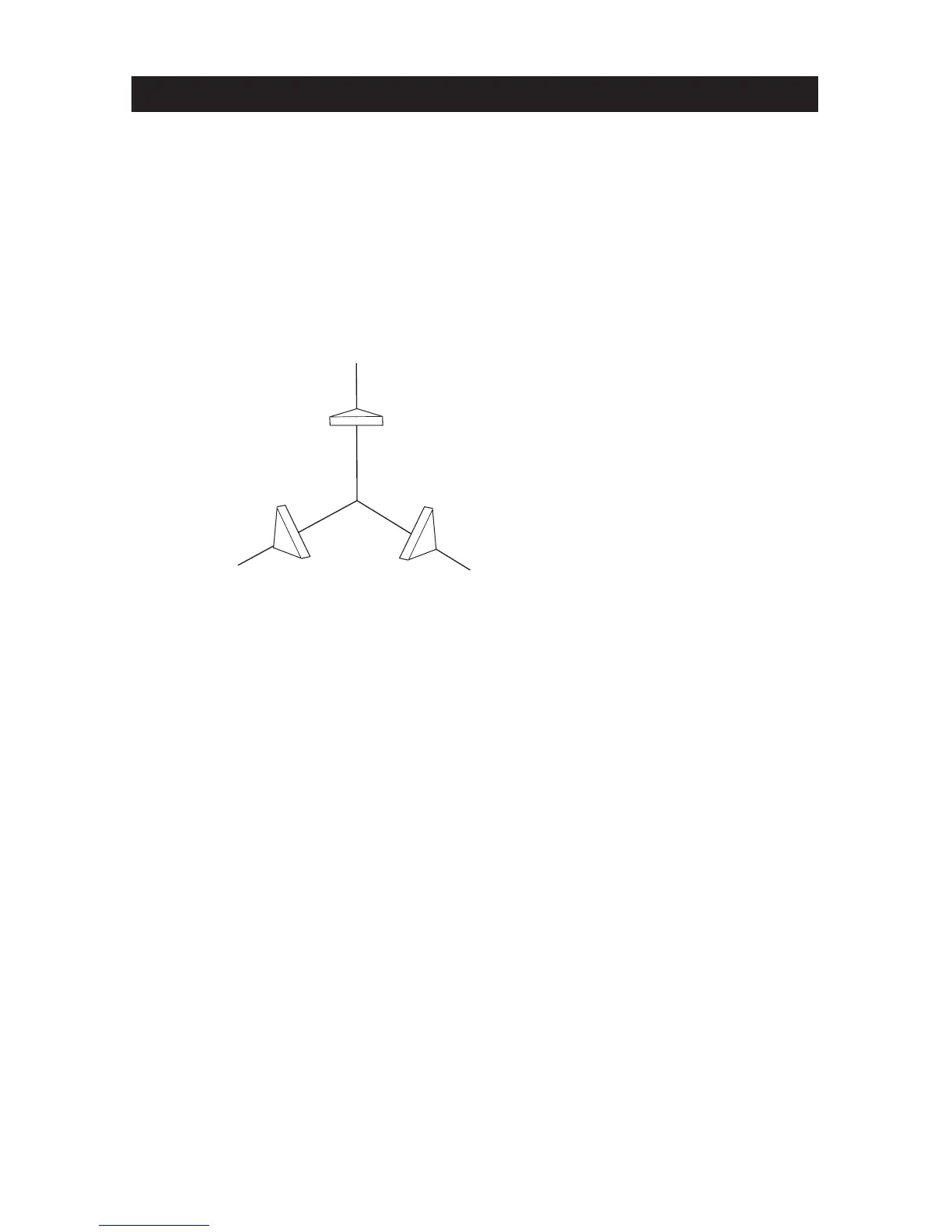

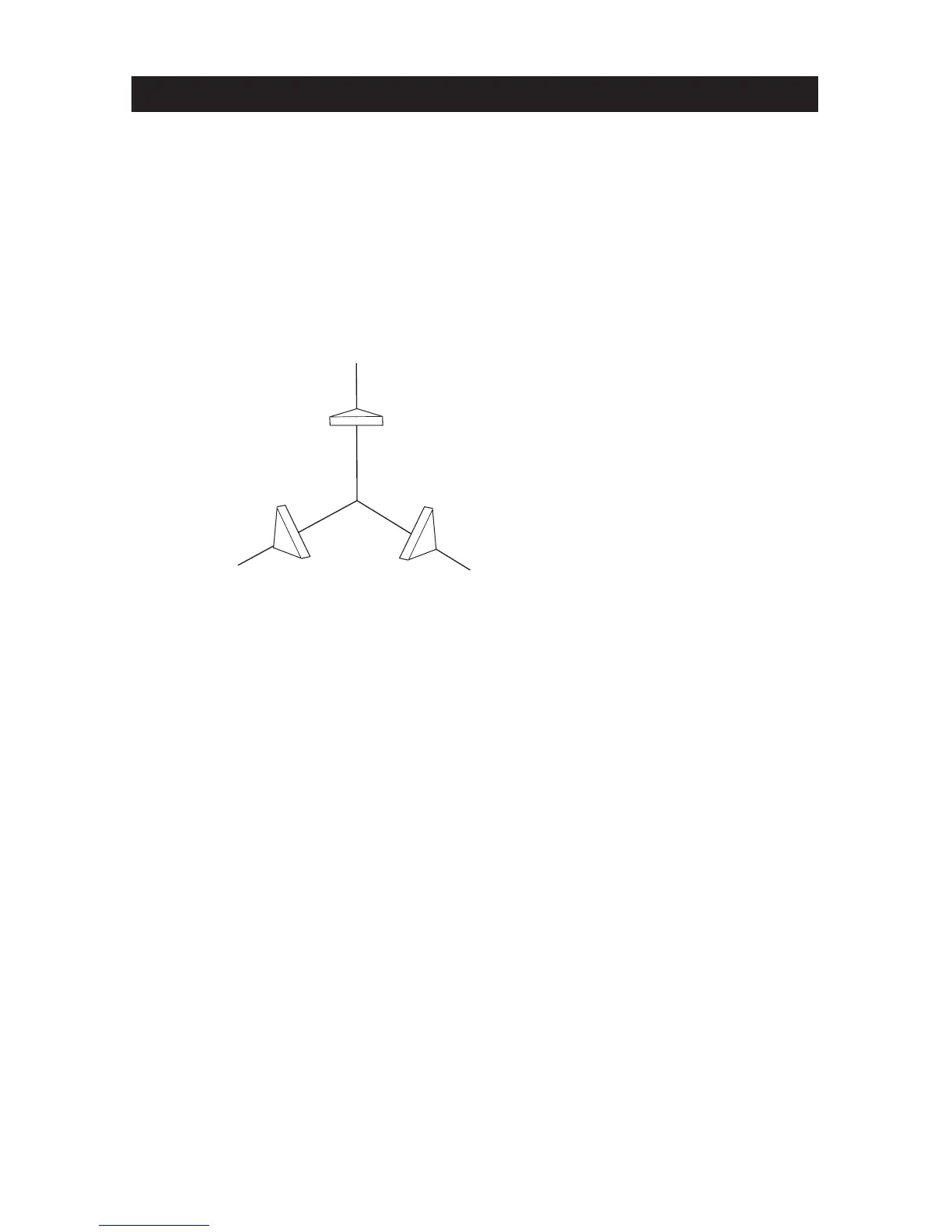

Use of triangle shaped braces is recommended to reduce panel vibration.

x=3" for S15L7, S12L7

x=2" for S10L7, S8L7

When using more than one subwoofer, each one should have it's own separate air space.

A terminal cup is recommended for making the wiring connection to your enclosure. If

necessary, a hole slightly larger than the wire used, sealed with RTV silicone, is acceptable.

Don't move the wire until the silicone is completely dry.

Once the box is built, use RTV silicone to seal all the inside joints. The enclosure must be

air tight.

Do not use RTV silicone around the woofer opening. Silicone on the basket will void your

warranty! If necessary, use rope caulk or plumber's putty.

Add enough polyester fiber material (commonly used as pillow stuffing) to fill the box

half way. This will help smooth out the response of your woofer.

x

x

x

x

xx

Loading...

Loading...