7-3November 2002 06-235975-001

Kidde Gemini II System

enclosure must not be exposed to ambient temperatures

below 32°F (0°C) or above 120°F (49°C). Relative humid-

ity should not exceed 93% non-condensing @ 100°F

(36.5°C).

Position the enclosure in a readily accessible and easily

visible location about 44 inches (112 cm) from the floor in

order to place the display panel at a convenient viewing

height. Ensure there is a 1-1/2 foot clearance in front of the

enclosure for the door to swing open.

The Main Control Panel and Remote Hazard Unit enclo-

sures are designed to be surface or semi-flush mounted.

Use screws or bolts no smaller than No. 10 (3/16”) in diam-

eter to secure the enclosure to wall studs or masonry walls.

Never mount the enclosure to drywall or plaster walls with-

out securing to studs.

The Remote Display Unit has mounting screw holes on the

sides as well, and can be flush mounted between studs.

The type of hardware is at the discretion of the installer, but

must be in accordance with good electrical and safety prac-

tices. All installation wiring must adhere to NFPA 70 (NEC)

and all state and local codes.

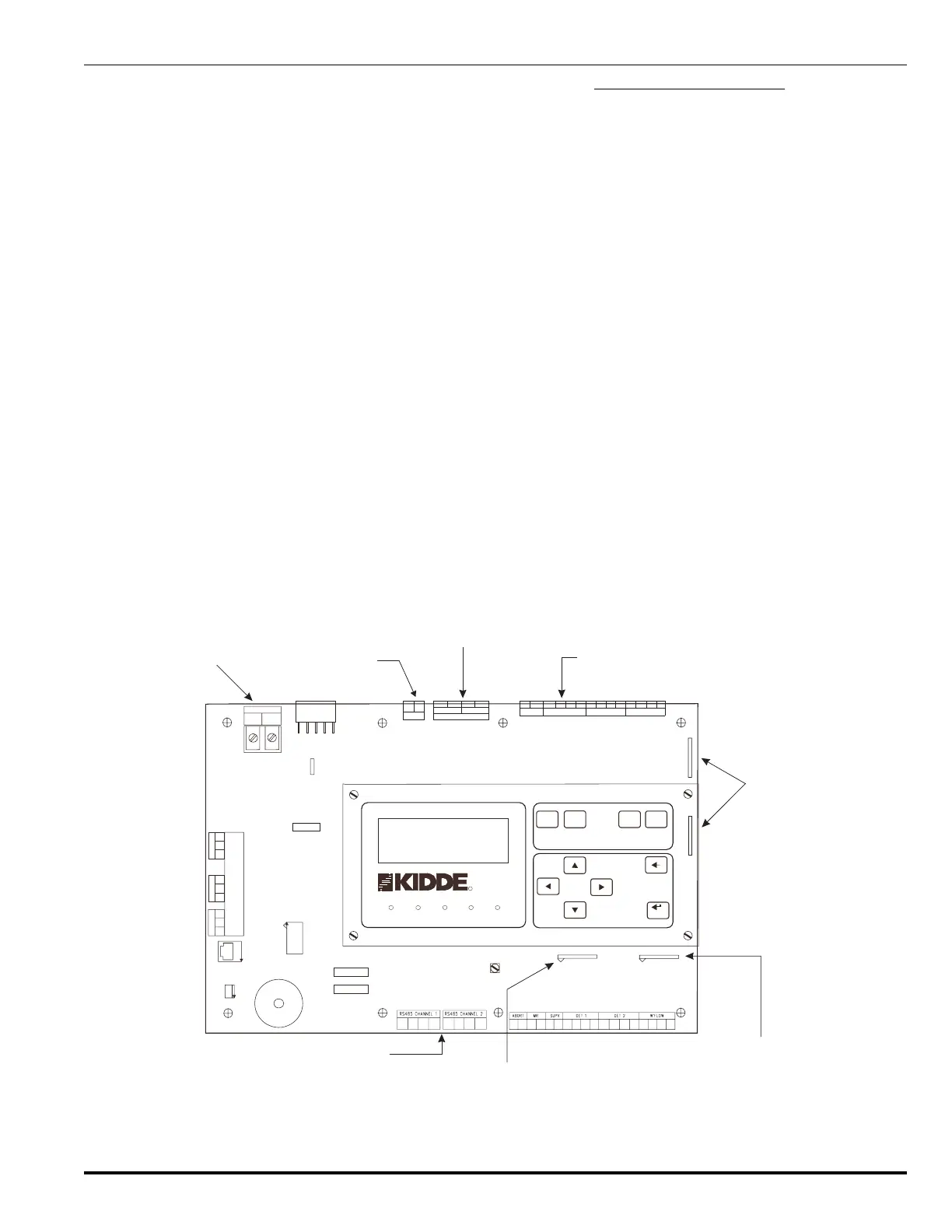

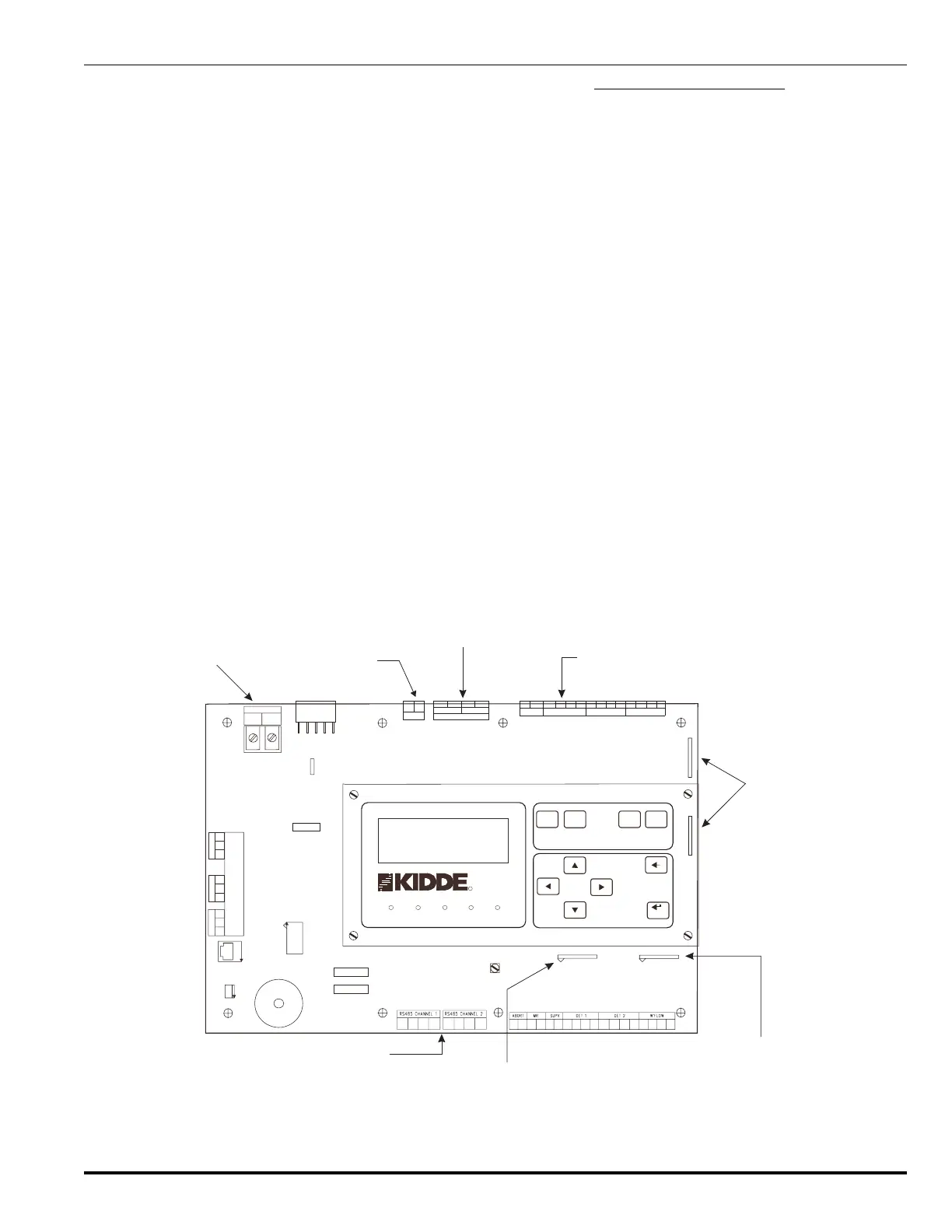

7-3.1.6 PRINTED CIRCUIT BOARDS

Figures 7-2, 7-3 and 7-4 show the layouts of the printed

circuit boards of the MCP, the RHU and the RDU respec-

tively.

7-3.2 Unit Installation Procedures

The first step in the installation procedure is to prepare sys-

tem layout and wiring drawings. The wiring drawings spe-

cific to a unit should be secured to the inside of its cabinet

after the installation is complete for future reference.

7-3.2.1 ENCLOSURE MOUNTING PROCEDURE

Once the locations of the system units i.e., the MCP, the

RHUs and RDUs is decided, the next step is to mount the

enclosures/backboxes using the following steps:

1. For the MCP and RHU, remove the Power Supply and

PCB/Display Assembly cartons from within the enclo-

sure and place them in a safe location.

2. Mount the MCP and RHU enclosures as follows:

a. Remove the front door of the enclosure. To remove

the front door, remove the ground wire, open the

door about 90° from the closed position and lift it

up until the door hinge pins clear the mating hinge

sockets on the left side of the enclosure.

b. Remove knockouts as required (taking the battery

location at the bottom of the enclosure into consid-

eration).

c. To mount against a wall, place the mounting screws

(not provided) in the wall to match the keyholes at

the back of the enclosure. Leave about ¼” of both

J4

J5

TB6

TB7

TB4

TB1000

TB5

J1

W200

W109

W101

W104

NO

C

NC

A

M

L

NO

C

NC

T

L

B

NO

C

NC

P

O

R

INTERNAL

SOUNDER

LCD

CONTRAST

VR1

W108

AC & 24V

PSU PLUG

J1001

J1000

AC MAINS INPUT

L

N

TB3

G

TB1: AC Power

TB3: 24 Vdc

output

TB6: Indicator, release and

stop valve outputs

Battery connection

Shorting links W 108 & W109,

sounder output circuit

Shorting link W104; pins 1-4 are for

waterflow input and pins 5-8 are for

the data highway

Shorting link W101,

detection input circuit

TB7: RS-485 data channel

+

-

+-+-

1+ 2+ 2- 1- 1+ 2+ 1- 1+ 2+ 2- 1-

2-

A1 B1 A2

B2

A1 B1 A2 B2

+

R2-

R2+ R1-

R1+

1- 2- 1- 2-1+ 1+2+ 2+

-

SOUNDER 1

SOUNDER 2

RELEASESTOP V

-

+

+

_

+

RESET NON-RESET

_

AUX 24 V OUT

BATT

MAIN

CONTROL

PANEL

POWER ON

ALARM

TROUBLE

SUPERVISORY

SIGNAL

SILENCED

RESET

ALARM

SCROLL

SYSTEM

CONTROLS

SIGNAL

SILENCE

SUP/TBL

SCROLL

MENU

CONTROLS

CANCEL

ACCEPT

R

R

W1000

1

2

3

Figure 7-2. Main Control Panel Printed Circuit Board

Loading...

Loading...