7-606-235975-001 November 2002

Kidde Gemini II System

3. Connect the positive and negative terminals of the set

of batteries to BATT+ and BATT- on TB1000 as shown

in Appendix E.

Note: Batteries should be placed in service within three

months of shipment date if stored at about 70°F,

or within one month if stored at 100°F. For longer

storage time, they require charging per

manufacturer’s specification to prevent permanent

loss of capacity.

12 Ah 12 Vdc

Battery

J4

J5

TB6

TB7

TB4

TB1 TB2 P1&P2

TB3

TB5

J1

W200

W104 W101

W109

W108

ISP RES

SW90

CPU RES

SW1

WATERFLO

W

++

SUP'V

+

ABORT

+

Man

Rel

+

DETECTOR

2

++

DETECTOR

1

++R-

24V DC

OUT

+R+

24V

IN

+

AC MAINS

INPUTLEN

N

L

NO

C

NC

A

M

L

NO

C

NC

T

L

B

NO

C

NC

V

R

F

+

SOUNDER

1

+

STOPV

+

+

SOUNDER

2

++

RELEASE

+

A

CHANNEL

1

BABA

CHANNEL

2

BAB

BATTERY

+

INTERNAL

SOUNDER

LCD

CONTRAST

VR1

-+- +

12 Ah 12 Vdc

Battery

MAIN

CONTROL

PANEL

POWERON

ALARM

TROUBLE

SUPERVISORY

SIGNAL

SILENCED

RESET

ALARM

SCROLL

SYSTEM

CONTROLS

SIGNAL

SILENCE

SUP/TBL

SCROLL

MENU

CONTROLS

CANCEL

ACCEPT

02-06-01

ALM00 SUP0 TBL00

MCP V 1.0

SYSTEM STATUSNORMAL

12:00

R

R

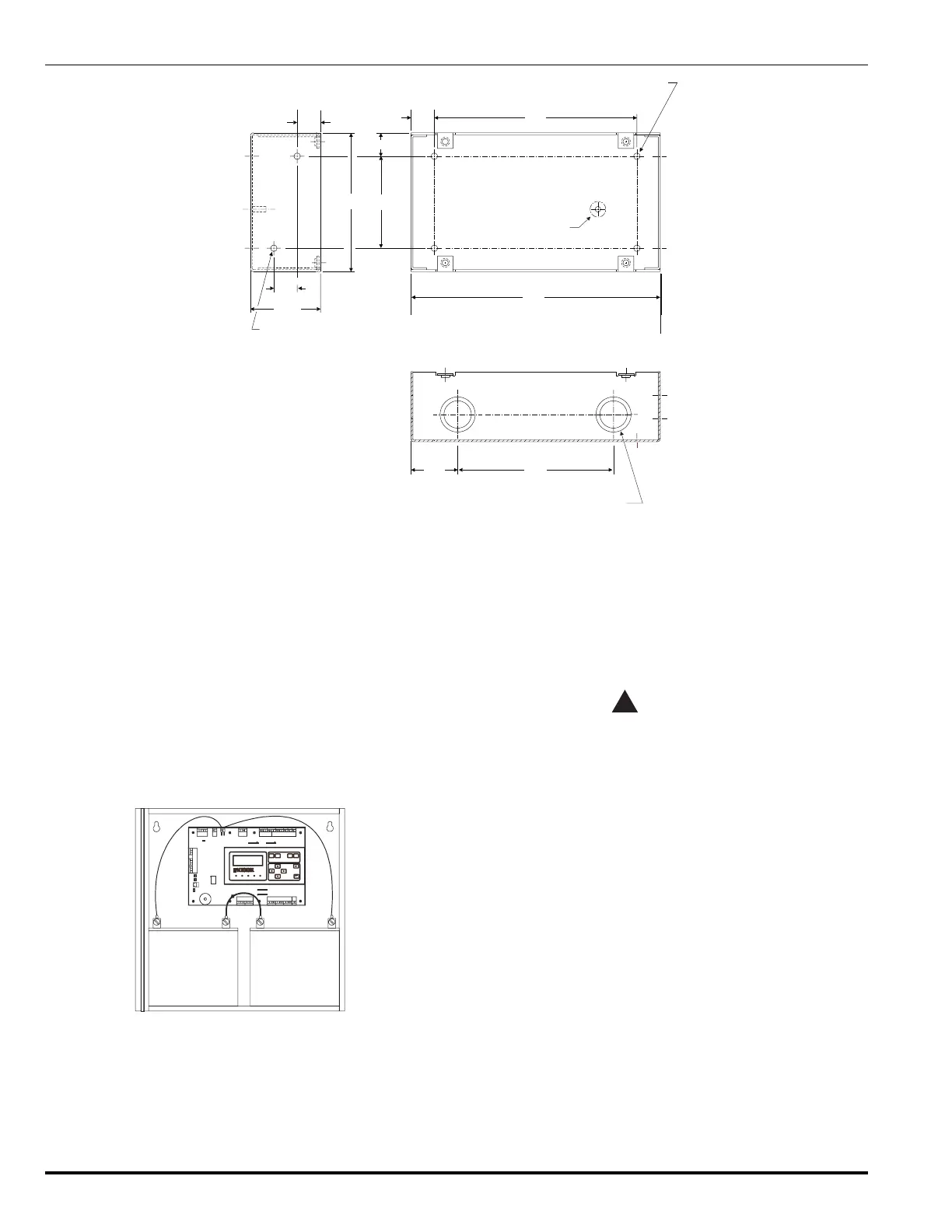

Figure 7-7. Backup Battery Location

7-3.2.3 CONNECTING AC POWER

AC power must be provided to the MCP and RHU internal

power supply using a 3-conductor 14 AWG cable. The AC

power cable is to be run through a one-inch conduit from a

dedicated, 15-ampere circuit breaker. The conduit must be

attached to the left side of the enclosure through one of the

upper left corner knockouts.

High voltages may be present when connecting

AC power to the MCP and RHU. Take suitable

precautions to avoid injury.

Perform the following steps to connect AC Power to the

MCP and RHUs:

1. Ensure the circuit breaker at the dedicated AC power

source is in the OFF position.

2. To ensure correct AC supply supervision, for 120 Vac

operation only, cut the leads and discard component

W200 on the MCP and RHU (see Figures 7-2 and

7-3). For 240 Vac operation, W200 must be left intact.

3. Upon completion of the initial installation steps as de-

scribed in step 2 and Paragraphs 7-3.2.4 and 7-3.2.5

for the MCP and RHU, attach the 3-conductor AC power

cable to TB1 on the printed circuit board (see Appen-

dix E) for the MCP and RHU respectively.

7-3.2.4 INSTALLING THE MAIN CONTROL PANEL

(MCP)

1. Install the MCP using the following steps:

a. Make all conduit connections into the MCP

enclosure.

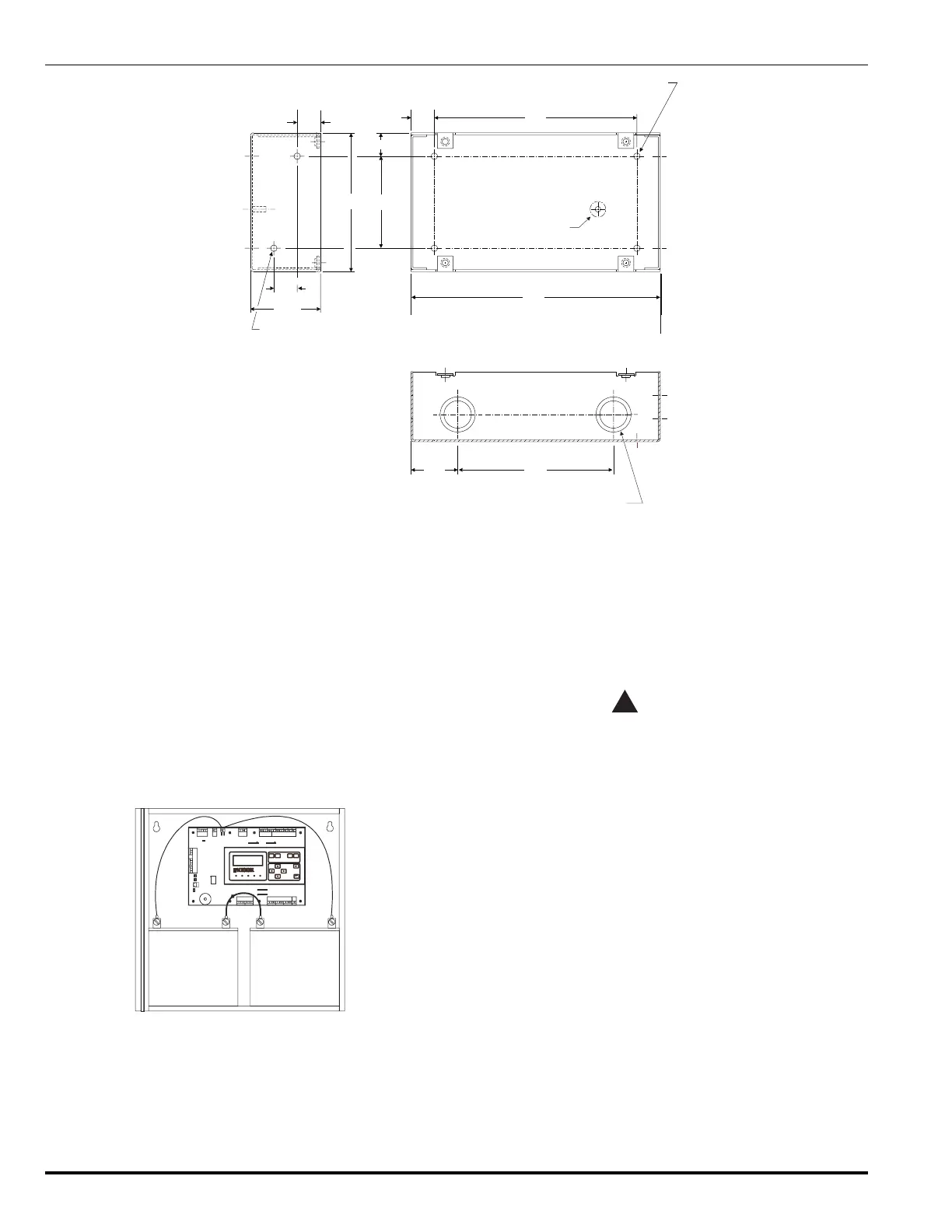

0.75”

0.75”

0.75”

8.0”

5.0”

1.5”

6.5”

2.25”

0.75”

.215 diameter - 2 holes on

each side for a total of 4.

4.45”

2.9”

1/2” - 3/4” (.875 - 1. 125) diameter

combination knockout in 2 places on

top and bottom for a total of 4.

.218 diameter - 4 holes on

back surface.

ground

Figure 7-6. Dimensions, Remote Display Unit

Loading...

Loading...