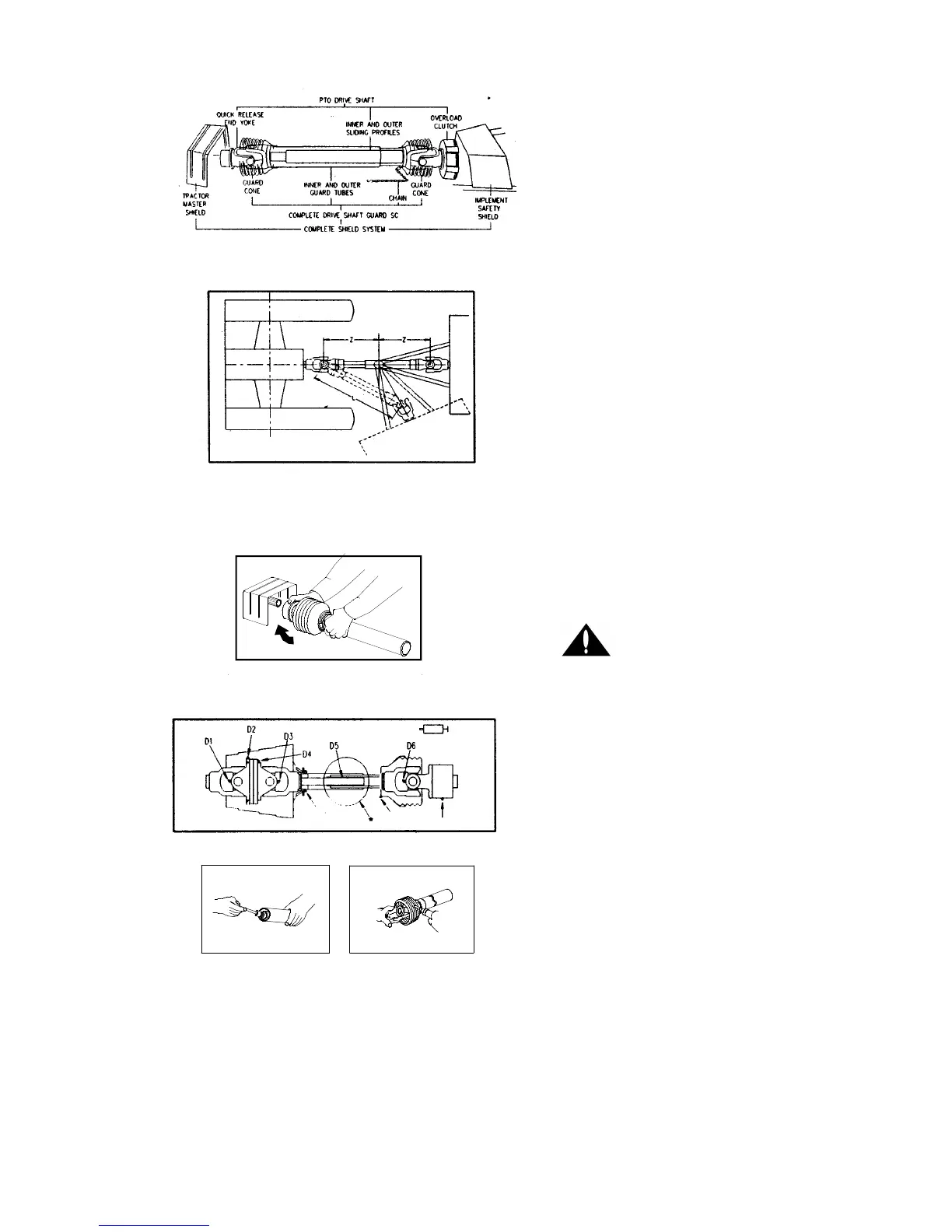

A. Only use a completely shielded drive sys-

tem:

PTO drive systems with complete shielding,

include the tractor master shield and imple-

ment shielding installed all the time. If any

component of the shield system has been

removed for any reason it, or an identical

replacement part, must be installed before

operation.

B. Maximum Joint Angles:

1. Joint (Standard Type)

Continuous operation - 25 degrees

Short duration - 45 degrees

Stationary - 90 degrees

Check shaft articulation and clearance zone!

Joint articulations of more than 45 degrees

lead to damage. Contact between PTO drive

shaft and tractor or implement (e.g. three point

hitch, drawbar) lead to damage.

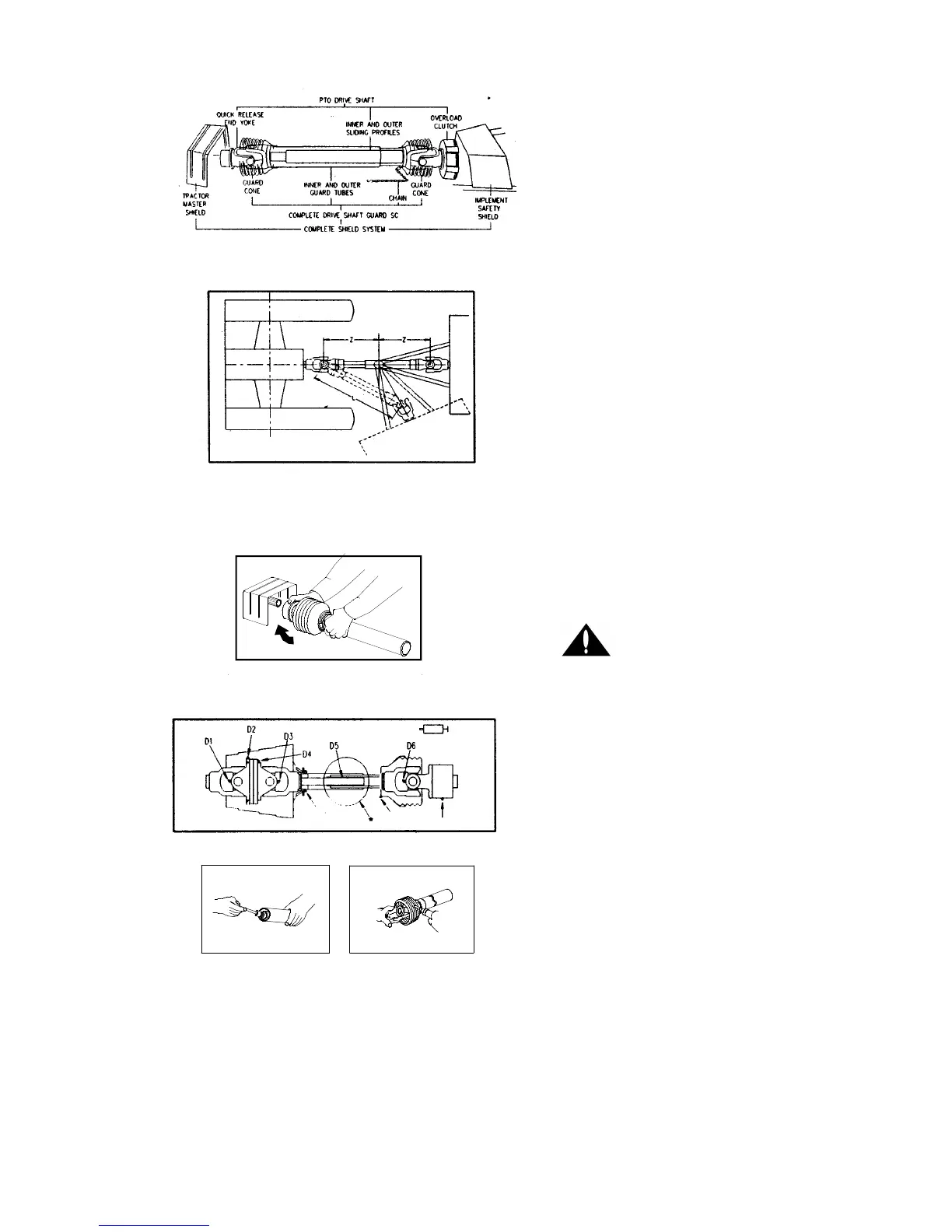

C. Coupling the PTO drive shaft (Fig. C1)

Twist Lock

1. Twist locking collar and simultaneously

push PTO drive shaft onto PTO shaft until

the locking device engages.

Check to insure all the locks are se-

cure before engaging the PTO drive shaft.

D. Lubrication (Fig. D1-D3)

Lubricate with quality grease before starting

work every 8 operating hours. Clean and

grease PTO drive shaft before each prolonged

period of non-use.

Molded nipples on the shield near each shield

bearing are intended as grease fittings and

should be lubricated every 8 hours of opera-

tion. Telescoping members must be lubricated

to operate successfully regardless of whether

a grease fitting is provided for that purpose.

Telescoping members without fittings should

be pulled apart and grease should be applied

manually. Check and grease guard tubes in

winter to prevent freezing.

E. Chains (Fig. F1-F3)

NOTE: The chain is intended to prevent the

shield from rotating against non-moving parts,

thereby preventing shield damage. A properly

installed chain will increase the service life of

the shield.

C1

D1

D2

D3

B1

Loading...

Loading...