16

EN

3.5 - Installation of the fixing brackets

and the gear motor

3.5.1 – Installation of the rear fixing

bracket

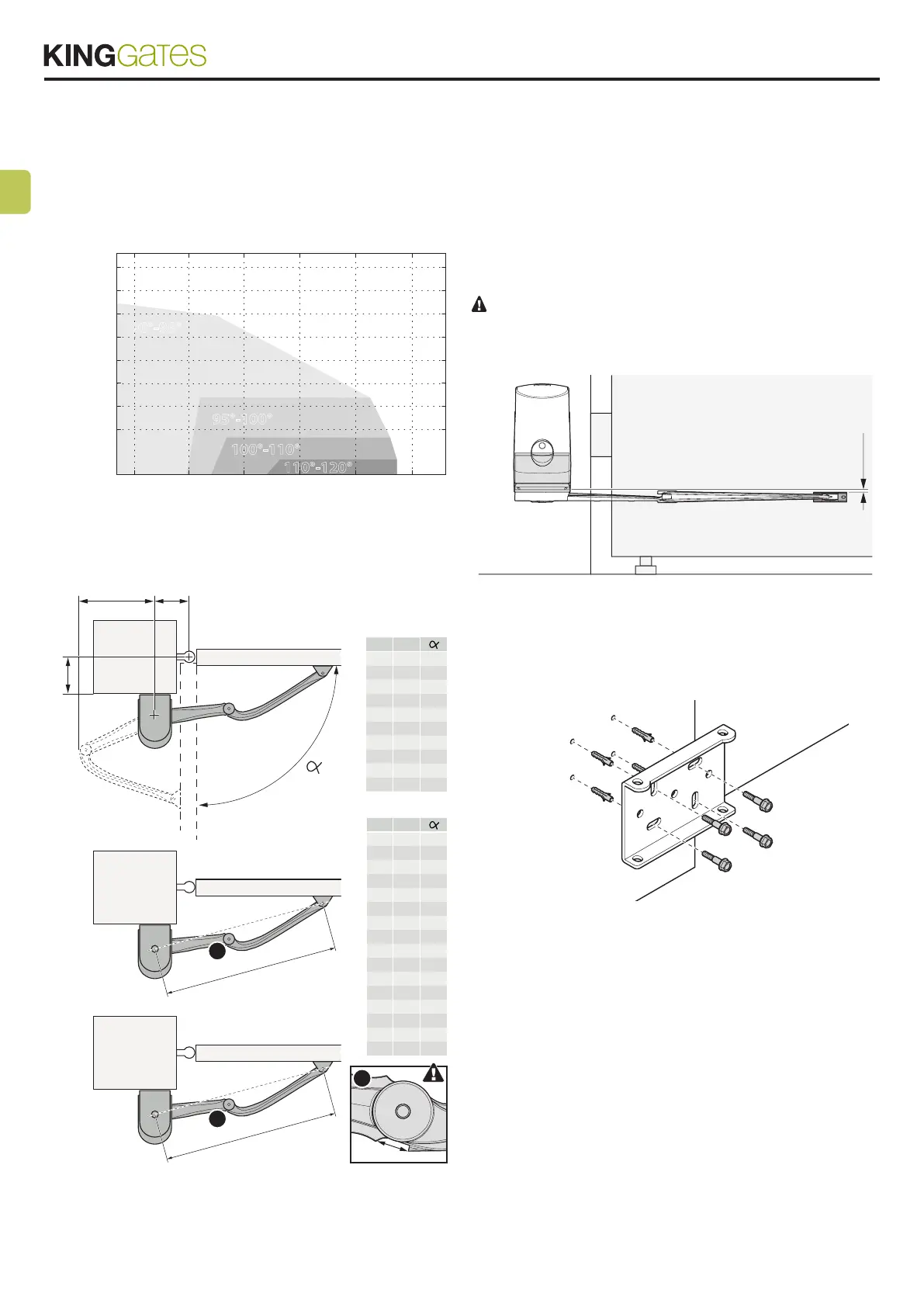

Calculatetherearbracketpositionusingchart 2.

Chart 2 (mandatory measurements)

100

150

200

250

300

350

400

450

100 150 200 250300 350

100°-110°

110°-120°

95°-100°

90°-95°

This chart is used to dene distances A and C and the leaf

maximum opening angle.

A

398

MO LINK 420

MO LINK 180

max 655 mm

AC

140 30 90

250 30 110

140 80 90

185 80 100

140 130 90

170 130 95

140 160 90

160 160 95

140 200 90

150 200 90

140 240 90

150 240 90

140 280 90

170 280 90

140 320 90

170 320 90

MO LINK 180

AC

140 30

250 30

140 80

190 80

140 130

170 130

140 160

160 160

140 200

160 200

MO LINK 420

max 800 mm

90

120

90

100

90

100

90

95

90

95

1

1

1

Fig. 3

01. Measurevalue“C”,thentraceastraighthorizontallineinchart

1againsttheobtainedvalued.Selectapointintheline,takinginto

accountthedesiredopening angle, suitable for the column.Trace

avertical linestartingfromthepointidentiedand obtainvalueA.

Beforeproceedingwiththeinstallation,makesurethatvalueAallows

toxtherearbracket,otherwiseselectanotherpointonthechart.

Finally,toxthebracketontheleaf,refertothemaximumdimensions

ofthearmingure3.Failuretocomplywiththebracketinstallation

distancesmayleadtoautomationoperationfaults,suchas:

- Cyclical movements and accelerations at some positions of the

stroke.

-Increasedmotornoise.

-Limitedopening,ornoopeningatall(incaseofcounter-leverxed

motor).

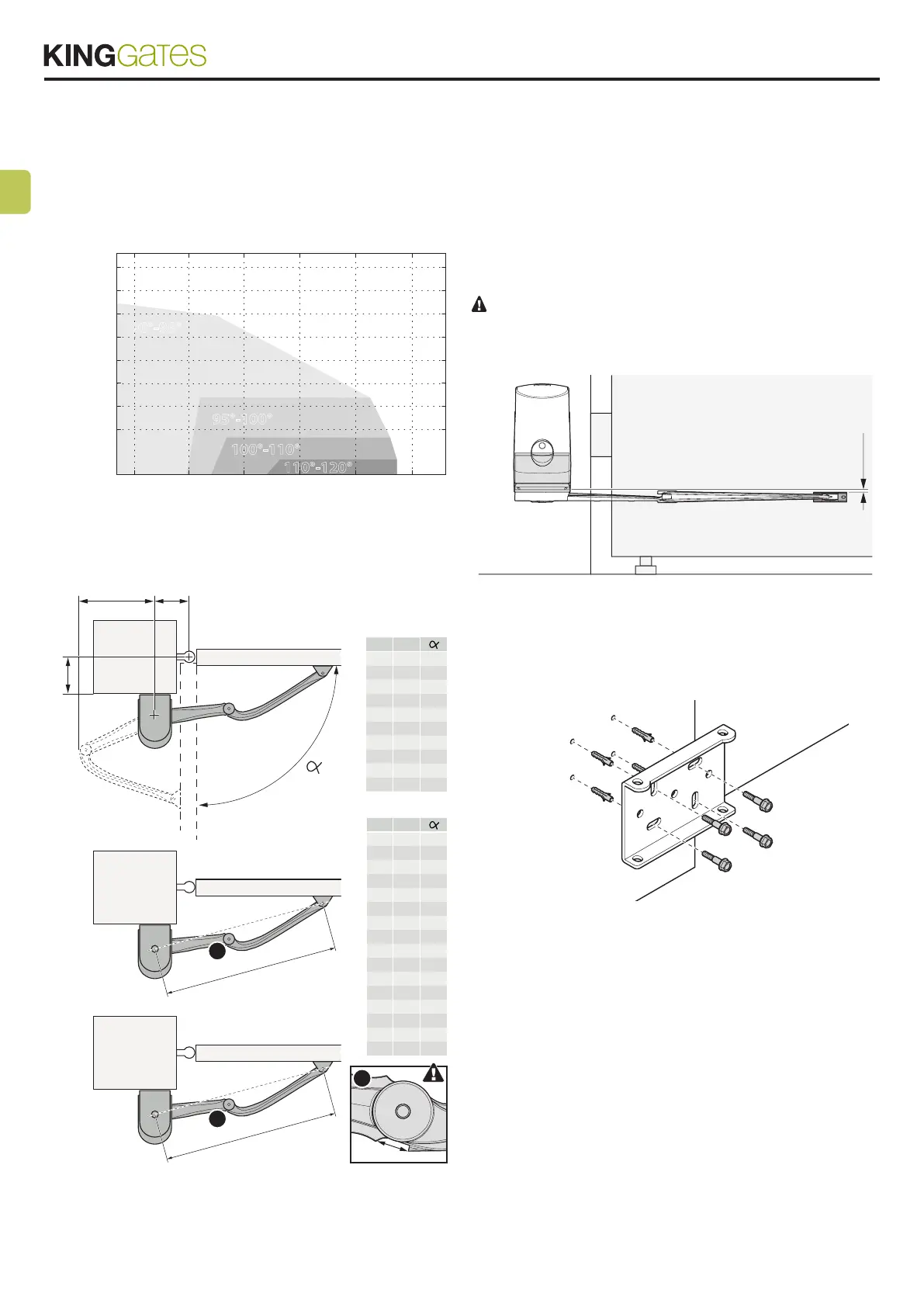

WARNING!–Beforexingtherearbracket,makesurethat

thefrontbracketwillbexedtoasolidpositionofthegate

leaf; the front bracket will have to be secured at a different

height than the rear bracket (Fig. 4).

5 mm

Fig. 4

02.Atthispoint,markontheleafandonthewalltheholesofthe

bracketswhichwillthenbeusedtoxthetwobrackets.

03. Fixtherearbracketofthemotortothewallcomplyingwiththe

dimensionsseenpreviously(g.5).

Fig. 5

Installation

examples

Loading...

Loading...