28

SPREADING MISTAKES

• Drive speed

• Incorrect spreading width:

• The spreading disc is not in horizontal position

• Drive speed is different than the table or not suitable for particular fertilizer

• Lack of cleaning of distributor discs and gates openings

• Poor quality fertilizer, Wet or humid

• Presence of excessive lumps

• Foreign body in the fertilizer

• Spreading exits clogged

• Parts of spreading disc worn or damaged

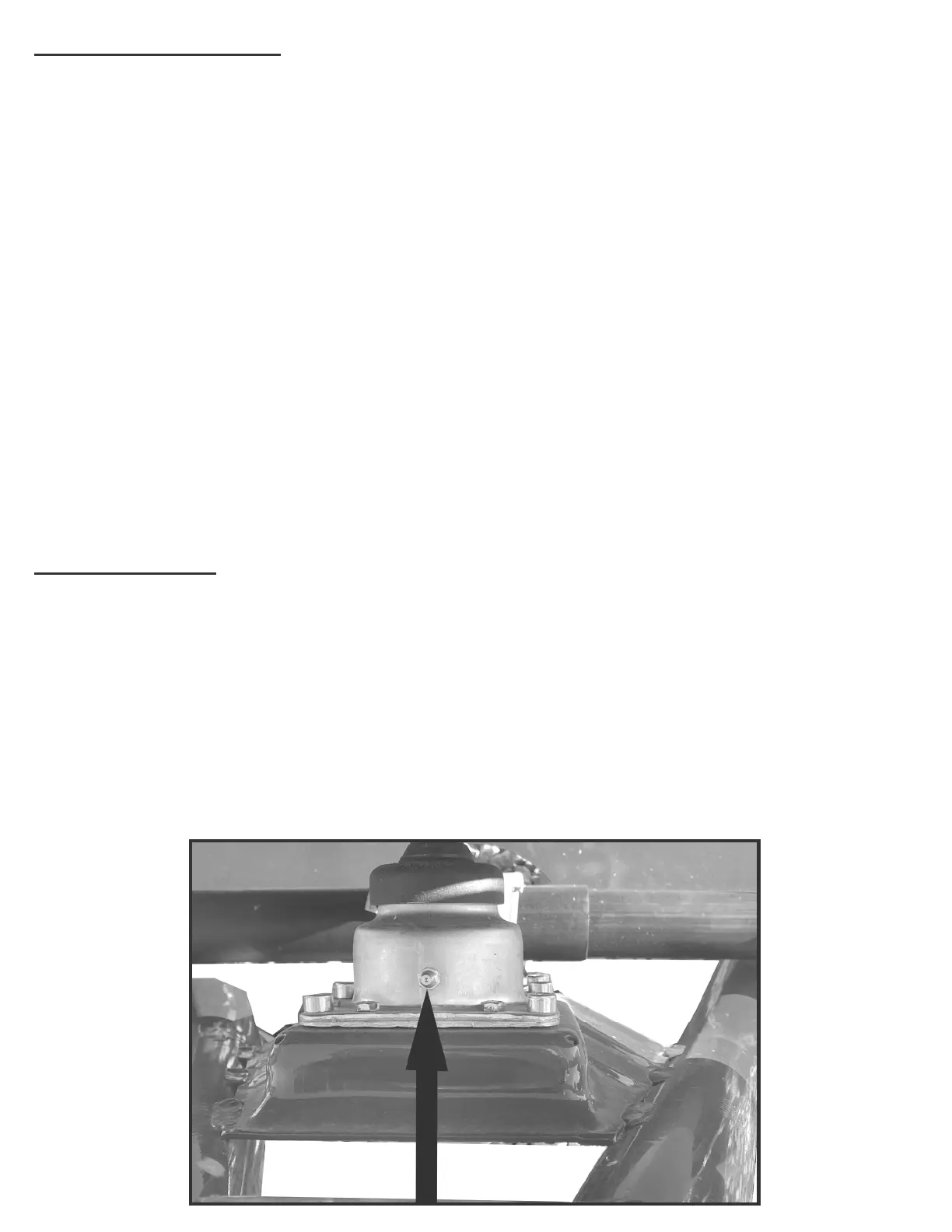

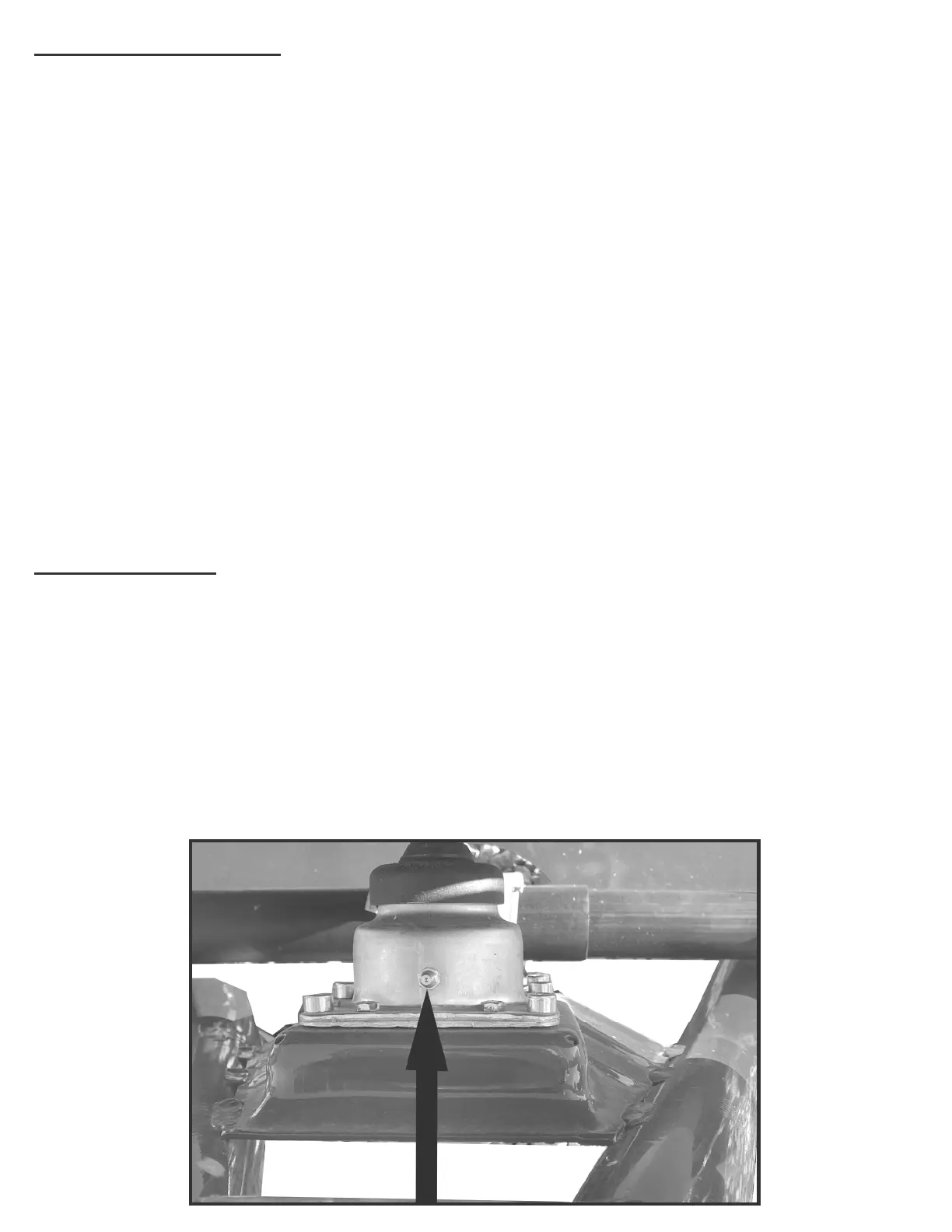

LUBRICATION

Before using the seeder for the first time, put at least (35 shots with a hand grease

gun) of grease in zerk shown below. After every 8 hours of use put in (3 to 4 shots

with a hand grease gun). DO NOT OVER FILL!

Make sure the grease zerks are clean from dirt and other foreign materials before

injecting the grease.

NOTE: Use only a grade Type II or Lithium tube grease.

POINT TO GREASE

Loading...

Loading...