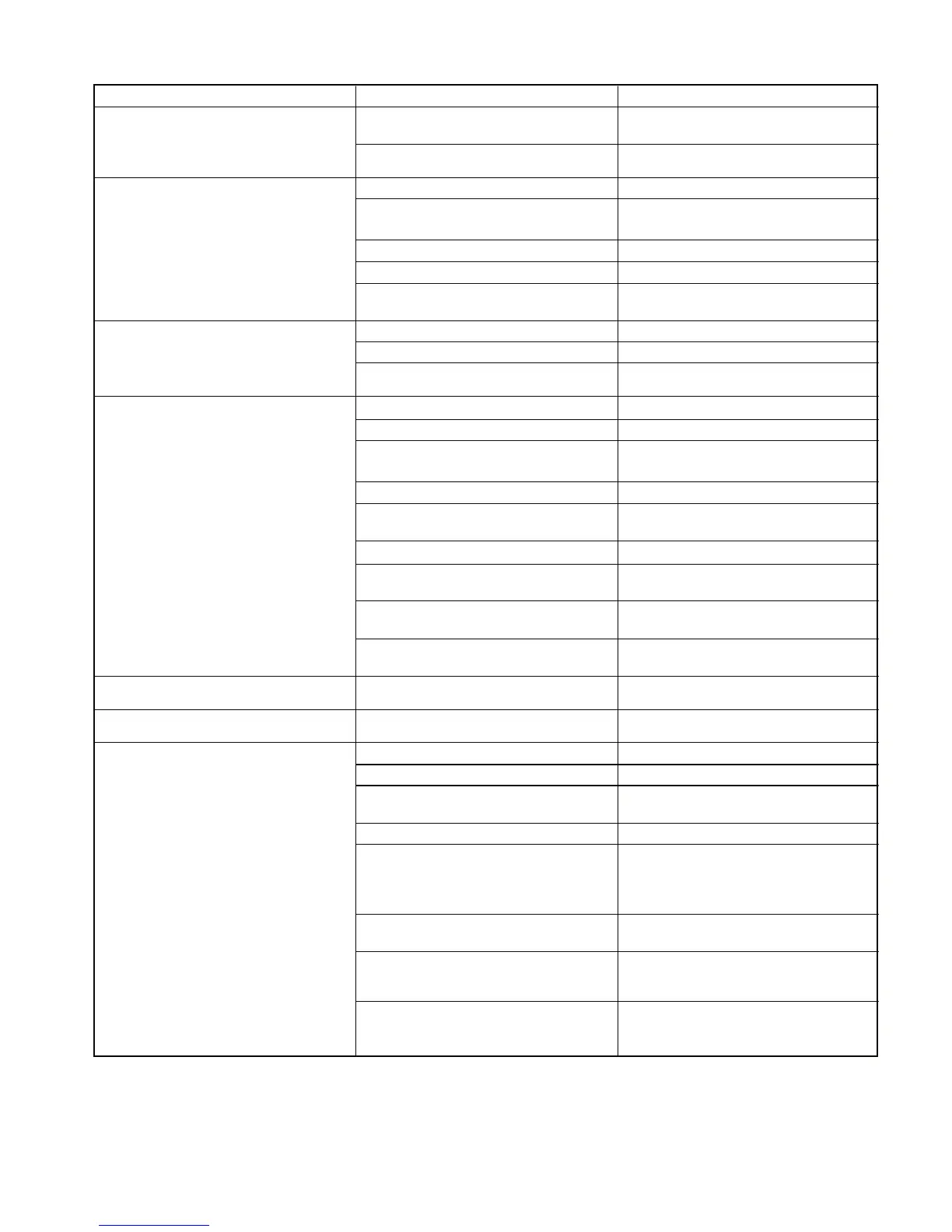

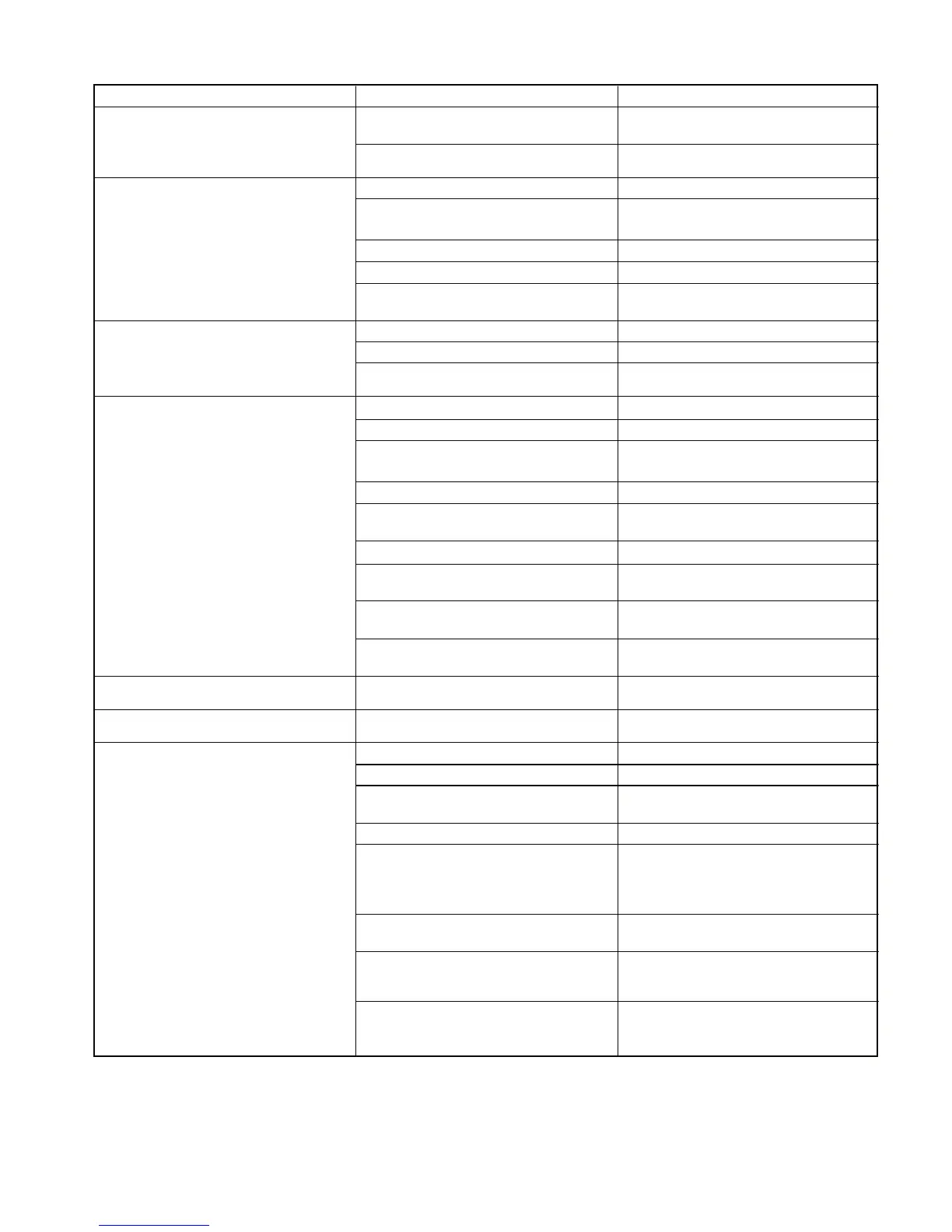

Symptom Possible Causes Corrective Action

Refrigerator temperature control set

too cold

A

djust refrigerator temperature

c

ontrol.

Refrigerator section too cold

Refrigerator airflow not properly

a

djusted

Check air flow.

Temp

erature controls set too warm Reset temperature controls.

Poor door seal Level cabinet. Adjust hinges.

Re

place gasket.

Dirty condenser or o

bstructed grille Check condenser and grille. Clean.

Faulty c

ontrol Test control. Replace if failed.

Freezer and refrigerator sections too

w

arm

Refrigerant shortage or restriction Check for leak o

r restriction. Repair,

evacuate and re

charge system.

Freezer temp control set too cold Ad

just freezer temperature control.

Faulty c

ontrol Test control. Replace if failed.

Freezer section too cold

Cold control c

apillary not properly

clamped to evaporator

Reposition clamp and tighten.

Temp

erature control set too cold Adjust temperature control.

Dirty condenser or o

bstructed grille Check condenser and grille. Clean.

Poor door seal Level cabinet. Adjust hinges.

Re

place gasket.

Interior light remains

on Check switch. Replace if necessary.

Faulty c

ondenser fan or evaporator

fan

C

heck fan and wiring. Replace if

necessary.

Faulty c

ontrol Test control. Replace if failed.

Refrigerant shortage or restriction Check for leak o

r restriction. Repair,

evacuate and re

charge system.

Refrigerant overcharge Check for overcharge. Evacuate and

r

echarge system.

U

nit r

uns continuously

Air in s

ystem Check for low side leak. Repair,

evacuate and recharge system.

U

nit r

uns continuously. Temperature

normal.

I

ce on evaporator See “Frost or Ice on evaporator”.

Unit r

uns continuously. Temperature

too cold.

F

aulty d

efrost thermostat Check thermostat. Replace if

necessary.

L

oose flooring or floor not firm Repair floor or brace floor.

Cabinet not level Level cabinet.

Tubing in conta

ct with cabinet, other

tubing, or othe

r metal

Adjust t

ubing.

Drip pan vibrating Ad

just drain pan.

Fan hitting another part En

sure fan properly aligned and all

attaching hardware a

nd brackets are

tight and not worn. Tighten or

replace.

Worn f

an motor bearings Check motor for loss of lubricant or

worn bearings. Replace if necessary.

C

ompressor mounting grommets

wo

rn or missing. Mounting hardware

loo

se or missing

Tighten hardwa

re. Replace

grommets if necessary.

N

oisy

operation

Free or l

oose parts causing or

allowing noise

during operation

Inspect unit for parts that may have

worked free or loose or missing

screws. R

epair as required.

Loading...

Loading...