DocumentNo.:KE-4025-06 10/50

7.2AirSupplyPort

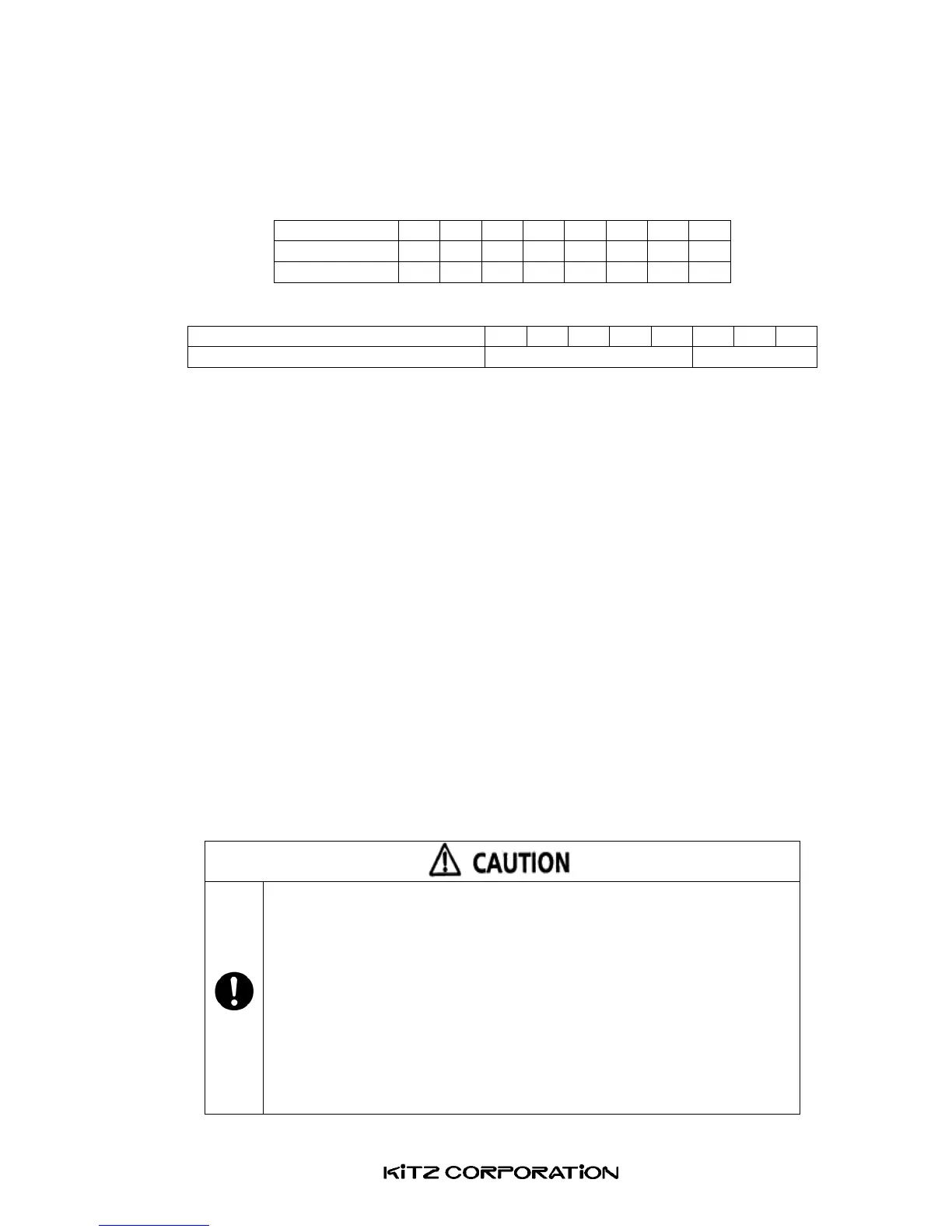

Selectcoppertubes(coveredoruncovered)forairsupplyandexhaustportsaccordingtothefollowingtable:

Nominalsizeofpipingthreads(Rc)

7.3Tubing

7.4SpecificationofSolenoidValves

TypeBactuatorsneed4-waysolenoid valves.4-way solenoid valves withoneOUT portpluggedor3-way

solenoidvalvescanenergizeTypeBSorTypeBSWactuators.ElectricwiringshouldbemadeasshowninFig.

8toFig.11,dependingontheplannedmodeofoperation.

KITZBSeriesactuatorsassembledwithsolenoidvalvesatthemanufacturerhavebeencompletewithcopper

tubing for air supply and exhaust pens. Users should make air supply tubing between air compressors and

solenoidvalves.

7.5PressureEqualizingValves(By-PassValves)

ManualoperationofTypeBactuatorsneedsapressureequalizingvalvebetweenthecylinderandthesolenoid

valve.

7.6SpeedControllers

Mountaspeedcontrollerbetweenthecylinderandthesolenoidvalve.

7.7Silencers

Installasilencerdirectlyintheexhaustportofthesolenoidvalve

Actuatorsize 0 1 2 3 4 5 6 7

TypeB 1/8 1/4 1/4 1/4 1/4 1/2 1/2 1/2

TypeBS/BSW 1/8 1/4 1/4 1/4 1/2 1/2 1/2 1/2

Actuatorsize 0 1 2 3 4 5 6 7

Tube(Outerdiameter×Innerdiameter) φ8×φ6 φ10×φ8

Formanualoperation of Type B actuators,theairresidue in the cylinder

must be discharged to the atmosphere. Ensure to install a pressure

equalizingvalvebetweenthesolenoidvalveandthecylinder.

Connect copper tubes (covered or uncovered) ofa suitable diameter and

wall thickness between actuators and pressure sources to maintain

sufficientairpressureduringvalveoperation.

Securely seal all of the tubing joints to avoid air leakage through the

connections,accessoriesortubes.Ensurethatloosesealingtapeendsdo

notextendintothetube.Itmayblocktheportsandaffecttheairsupplyto

theactuator.

Loading...

Loading...