DocumentNo.:KE-4025-06 21/50

13Troubleshooting

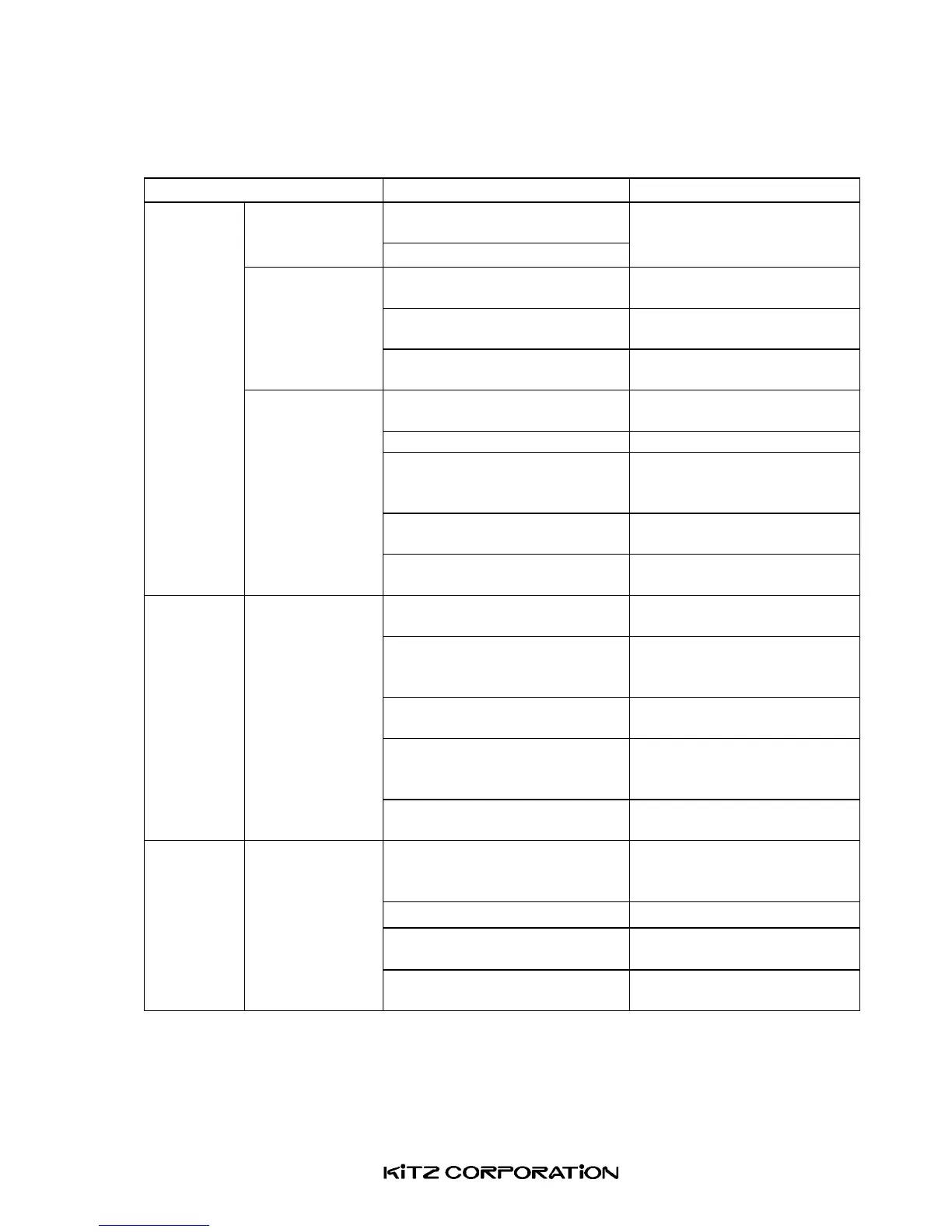

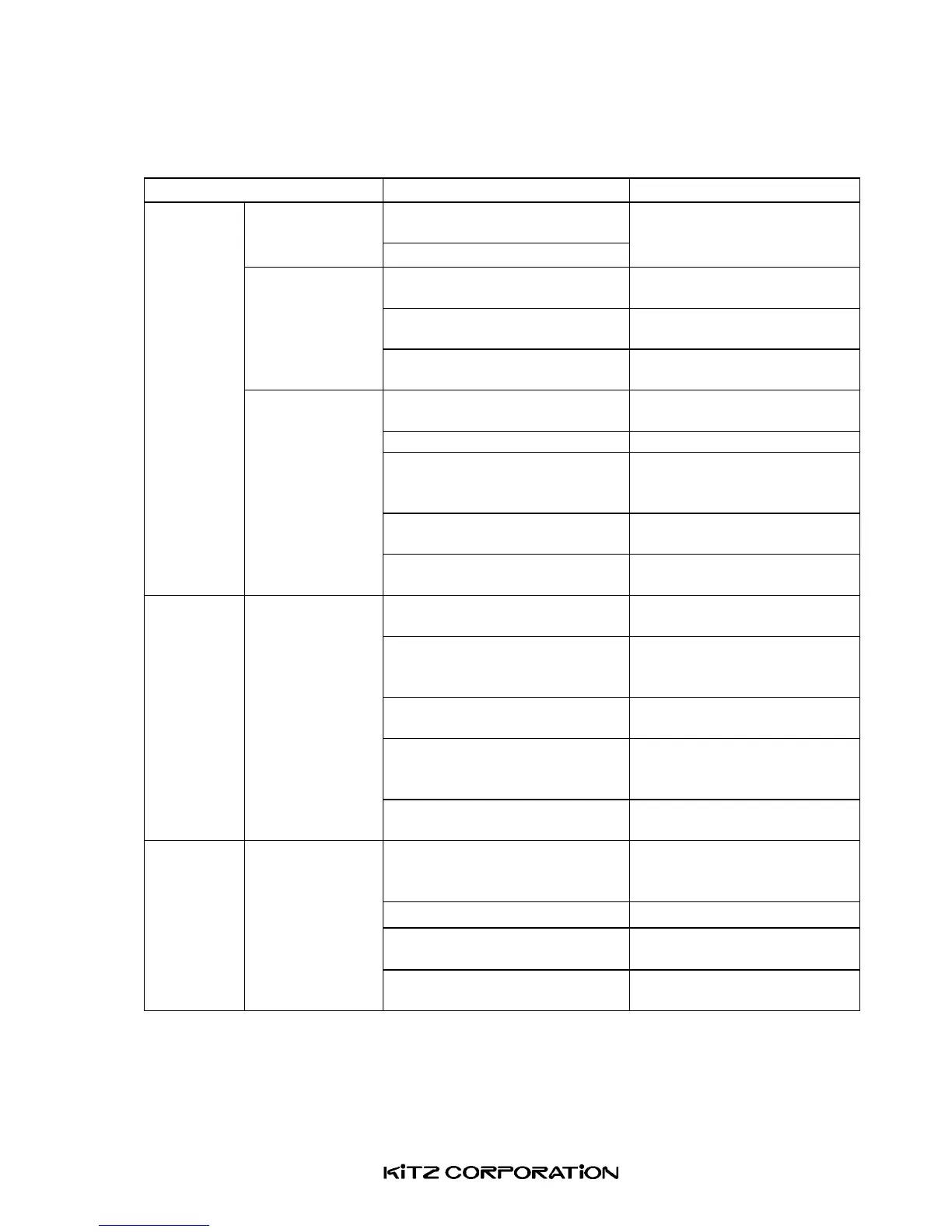

DetectedTrouble Causes RemedialMeasures

Failureofcompressororlackof

compressorcapacity

Airpressure

lowerthanthe

specified.

Airleakagefromtubing.

Inspectandrepairthe

compressorasappropriate.

Failureofcompressor

Inspectandrepairthe

compressorasappropriate.

Clogging,breakageorfreezingof

pipe

Checkandrepairthetubesas

appropriate.

Nosupplyofair

pressure.

Failureoffilterregulator

Disassembly/check/repair/replac

ementoffilterregulators.

Foreignobjectsstucktothe

valveseats

Disassembleandcleanthevalve.

Failureofactuators Replacethepartoractuator.

Increaseofvalveoperatingtorque

duetoforeignobjectsstucktothe

valveinterior

Disassemble/check/cleanthe

valveandreadjusttheactuator

operation.

Excessivelythrottledofspeed

controllers.

Readjustthespeedcontroller.

Valve

Malfunction.

Noactivationor

disturbed

activationof

actuatorsunder

fullairpressure.

Dustcapisnotremovedfromthe

exhaustport.

Removethedustcap.

Disconnection of electric circuits.

Checkthewiringoftheelectric

circuitandvoltage.

Defectiveelectromagneticcoils

Checktheexcessivevoltageand

currency.

Replacethecoils.

Waterintheelectromagneticcoils

orterminal.

Takewaterpreventionmeasures.

Inadequatevoltageorpowersupply

cycles(Hz)

Checkthespecifiedvoltageand

cycle(Hz)withthenameplate

andreplaceasappropriate.

Troublesof

Solenoid

Valve.

Noactivationof

energized

solenoidvalve;

Abnormalnoise;

Excessive

temperature

raise.

Shortcircuitinthesolenoidvalve

interior.

Checkthesolenoidvalveand

replaceitasappropriate.

Worn-outofthepistonOring

ReplacetheOring,or

disassembleandreassemblethe

solenoidvalve.

Foreignobjects Removetheforeignobjects.

Equalizingvalvesleftopen. Closetheequalizingvalve.

Abnormal

ExhaustAir

fromSolenoid

Valve

Airexhaustsfrom

thesolenoidvalve

whenactuatoris

notoperated.

Worn-outofthesealingpartsof

thesolenoidvalve

Checkthesolenoidvalveor

replaceitasappropriate.

Loading...

Loading...