Section 10

Troubleshooting

20413005

8-2012/Rev 05

10-8

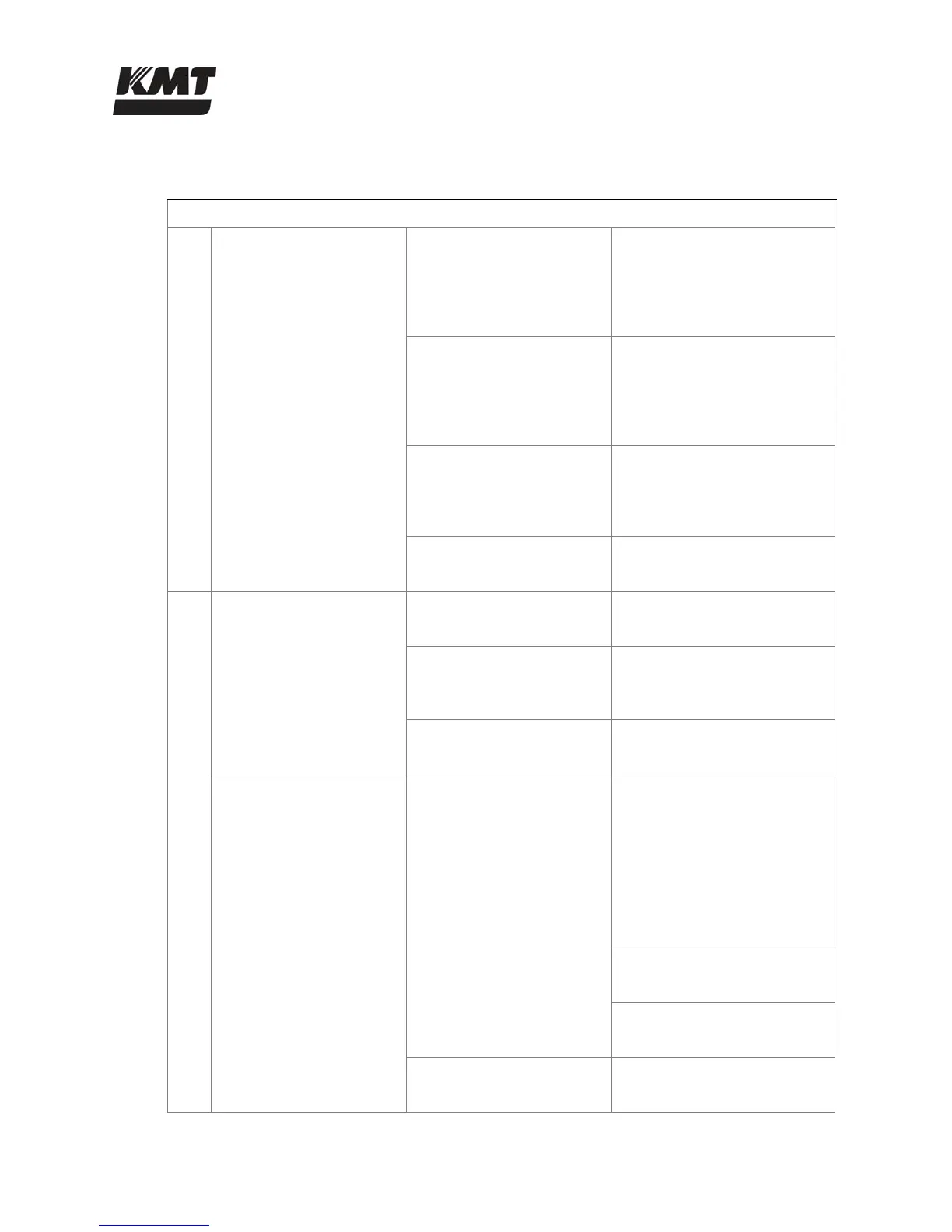

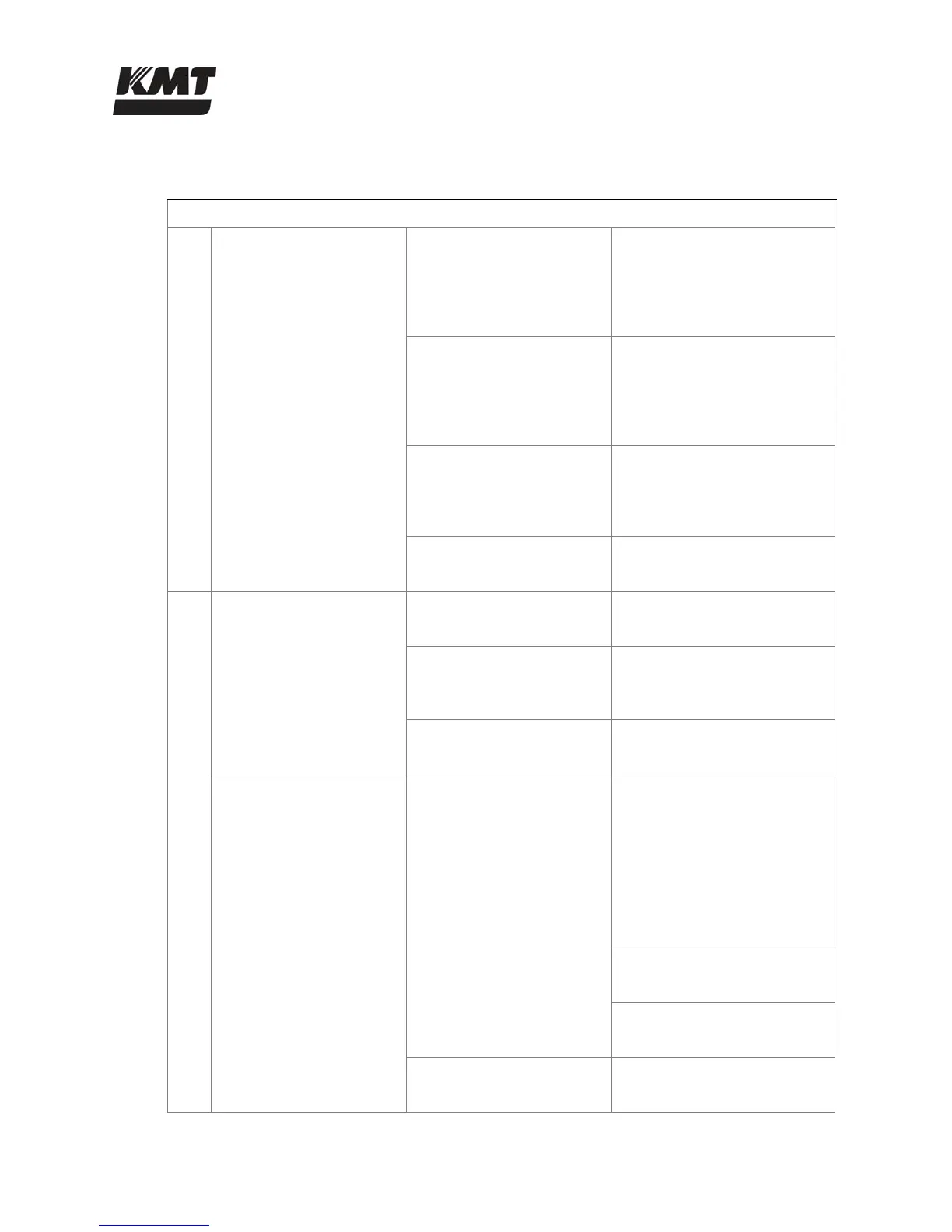

Table 10-1

SL-V Series Troubleshooting Guide

Malfunction Indication Comments

19.

Hot surfaces on the high

pressure cylinder

components

Leaking discharge check

valve

Inspect the condition of the seat,

poppet valve, spring, poppet pin

and sealing head surface on the

discharge end of the sealing

heads.

Leaking inlet check valve Inspect the condition of the

poppet valve, poppet retainer

and the spring, if applicable, on

the inlet end of the sealing

heads.

Damaged sealing head Check the cone flange surface of

the sealing head for scratches or

mechanical damage and replace

if necessary.

Damaged high pressure

cylinder

Check the high pressure cylinder

for cracks.

20.

Low cutting water supply

pressure

Restricted water supply Check cutting water supply flow

and pressure.

Clogged water filter Check the condition of the low

pressure water filter and replace

the filter element if necessary.

Trapped air Bleed the air from the cutting

water plumbing.

21.

Low cutting water pressure Low hydraulic pressure

setting

If operating in low pressure,

switch to high pressure

operation and check the

hydraulic pressure setting.

Not applicable when the

machine is equipped with the

optional proportional pressure

control.

Clean the high pressure

adjustment valve.

Clean the compensators on the

hydraulic pump.

Collapsed element in the high

pressure line filter

Check the element in the high

pressure line filter.

Loading...

Loading...