Section 7

Hydraulic System

20412971

8-2012/Rev 08

7-14

8. Remove the bolts that attach the hydraulic pump to the electric motor.

9. Support the hydraulic pump and slide it away from the motor, disengaging the flexible

coupling.

10. Inspect the flexible coupling for damage. If the flexible coupling is damaged it must be

replaced.

11. Inspect the metal splines on the motor coupling half. Wipe any residue, dirt or oil from

the motor coupling and the flexible coupling. Place the flexible coupling on the motor

coupling half, pushing it on as far as it will go.

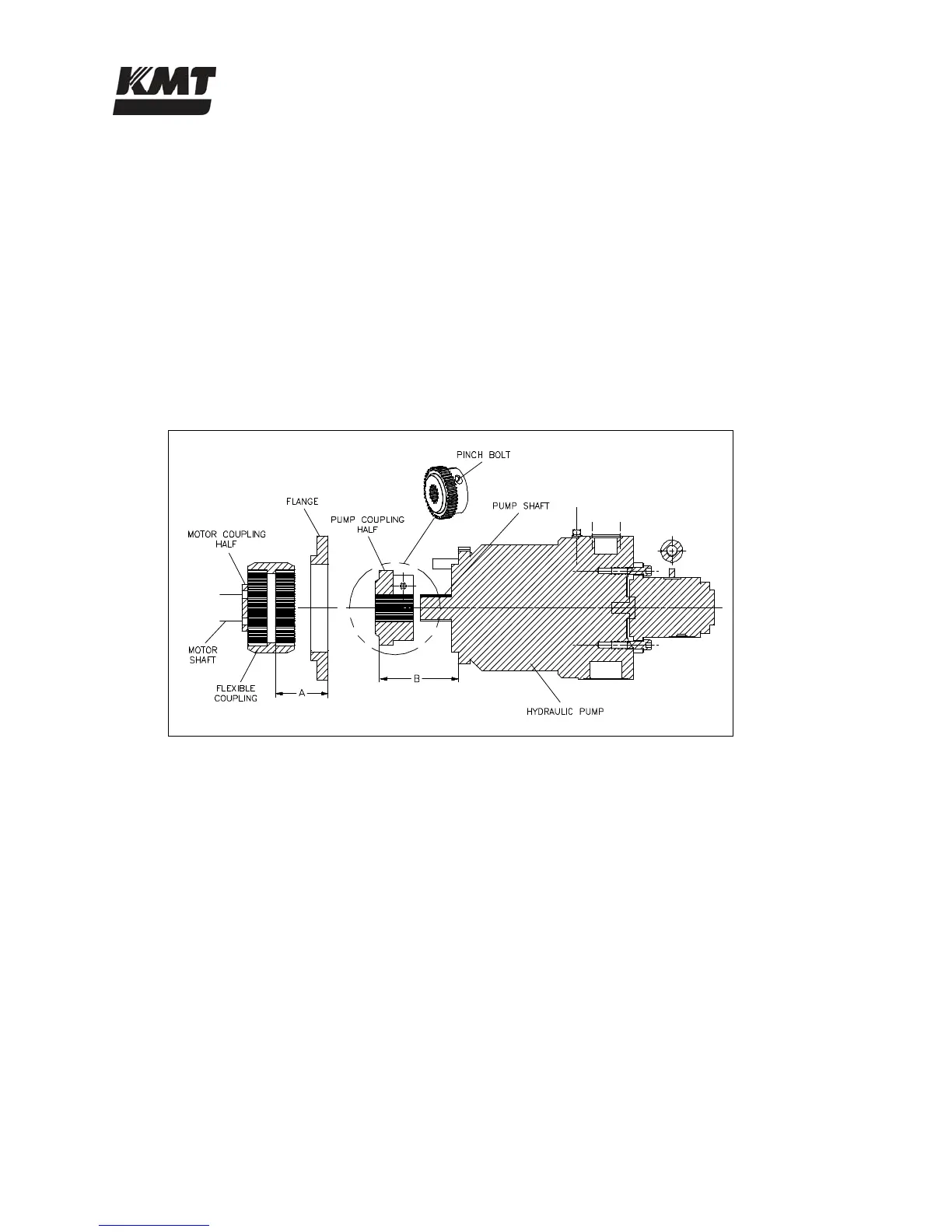

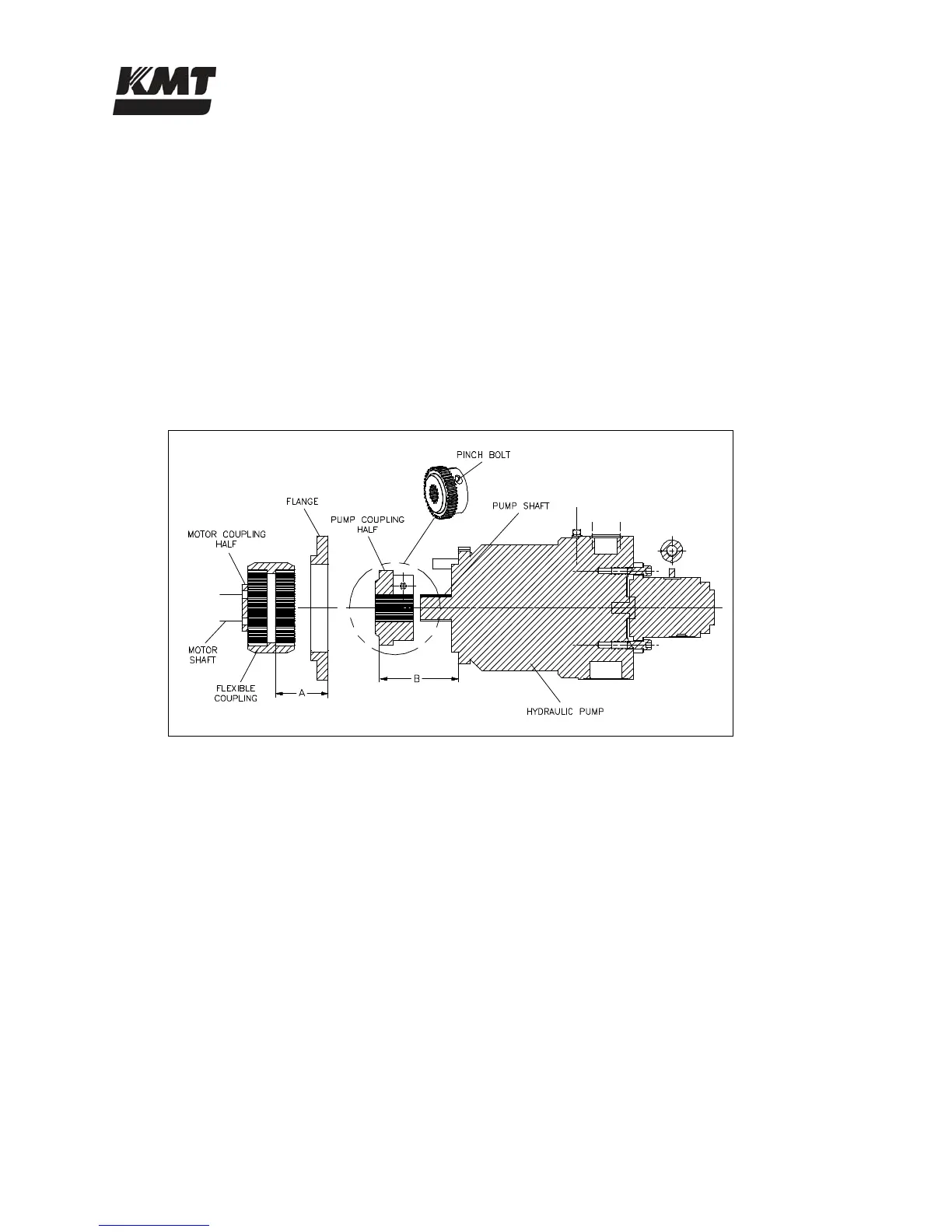

12. Take a measurement from the front face of the electric motor, the pump mounting

interface, to the outer face of the snap ring or solid band on the flexible coupling,

dimension A.

Figure 7-10: Pump Coupling Dimensions

From dimension A, subtract 5/16 inch for 30, 50 and 60 horsepower motors, and 1/4 inch

for 100 horsepower motors.

13. Loosen the pinch bolt in the pump coupling half on the old pump and remove the coupling

half. Inspect the metal splines for damage. If the coupling half is not damaged it can be

reused on the new pump.

14. Wipe any residue, dirt or oil from the pump coupling half. Slide the existing coupling

half, or a new coupling half if necessary, onto the splined shaft of the new pump.

15. Set the position of the pump coupling half by measuring from the pump mounting face to

the outer face of the coupling teeth, dimension B. On 30, 50 and 60 horsepower models,

B = (A - 0.313), on 100 horsepower models B = (A - 0.250).

16. Tighten the pinch bolt and torque to 36 ft-lbs (49 Nm) for 30 horsepower models, 63 ft-lbs

(86 Nm) for 50 and 60 horsepower models, and 218 ft-lbs (295 Nm) for 100 horsepower

models.

17. Place the hydraulic pump on the motor, ensuring the coupling teeth mesh into the flexible

coupling. Force should not be required.

Loading...

Loading...