Section 8

Electrical System

20412989

1-2012/Rev 08

8-8

Table 8-1

Sensors and Solenoids

Component Function

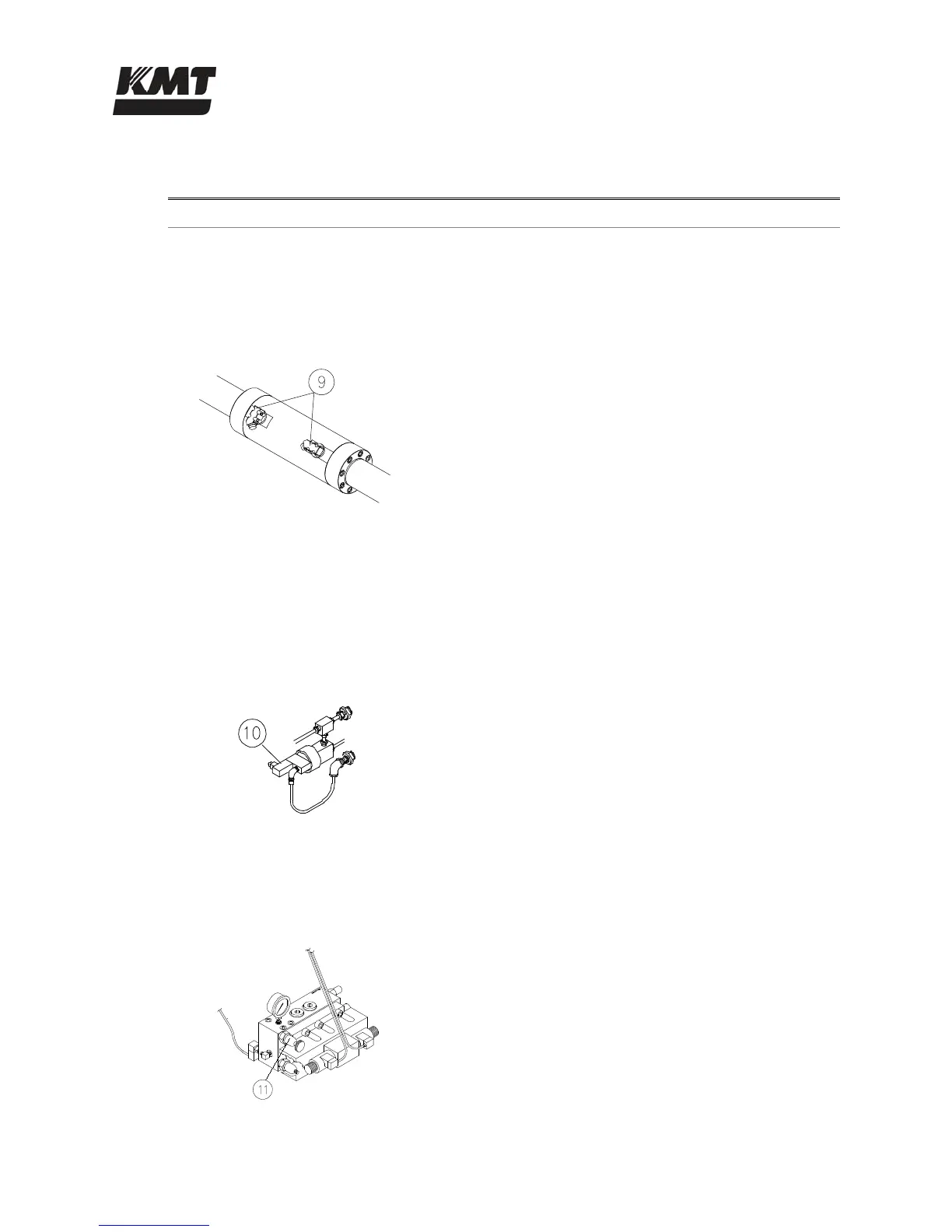

Hydraulic Cylinder

9 As pressurized hydraulic oil is sent to one side of the

hydraulic cylinder, it pushes against the piston,

moving it in one direction until it activates the

proximity switch at the end of the stroke. The

hydraulic flow is then sent to the opposite side of the

cylinder, and the piston reverses direction until it

activates the proximity switch at the opposite end of

the stroke.

The green light on the proximity switch indicates

there is power to the switch. The light turns red

when the switch is activated. The proximity

switches are magnetically activated by the presence

of the metallic surface of the piston. When the

switch is activated, it sends a signal to the PLC to

change the flow of the directional control valve and

reverse direction.

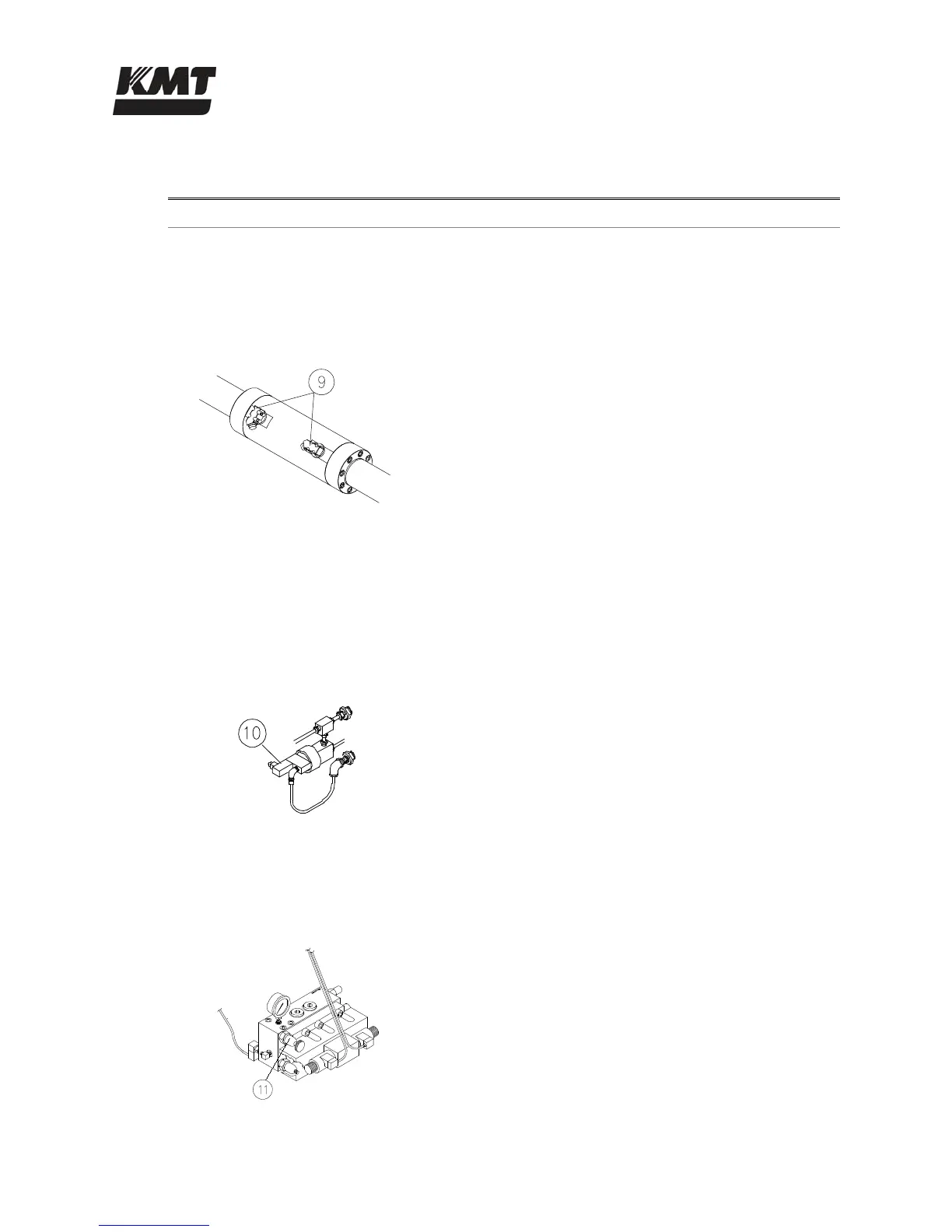

High Pressure Safety Dump Valve

10

When control power is removed, the safety

dump valve releases the stored pressure in the

intensifier and high pressure delivery lines. The

high pressure dump valve assembly includes a

normally open high pressure water valve and a

solenoid operated air valve.

The normally open pneumatic dump valve is

held closed by air pressure. When the air

supply is interrupted from an emergency stop,

the valve opens and allows water to flow

through the valve. Pressure is released in the

intensifier and the high pressure water stream

exits through the drain.

Proportional Pressure Control

11 Optional proportional pressure control allows the

operator to select or vary the hydraulic operating

pressure from the control panel or from a remote

console. An electronically controlled hydraulic

cartridge valve, mounted on the hydraulic manifold,

receives a signal from the PLC and automatically

makes the operator selected adjustments.

Loading...

Loading...