KV3000 Kinematic Viscosity Bath

Operation and Instruction Manual

KV3000-Manual

-16-

NOTE: Do not attempt moving the bath

when filled with fluid medium. Drain all fluid

before moving or relocating the instrument. See

section 7.2 of this document. Sudden starting

and stopping could result in hot bath fluid being

forcefully ejected from the bath. It could also

result in overbalancing and tipping over the

instrument.

NOTE: Do not drain the bath until the fluid is at

ambient temperature.

Distilled water will be suitable.

Koehler supplies highly

refined white technical oil

(part # 355-001-001) that

contains an oxidation inhibitor

to limit clouding at higher

temperatures.

CAS# 8042-47-5

Minimum Flash Point: 120°C

(248°F)

Fire Point: 202°C (395°F)

Koehler supplies a clear

silicone heat transfer fluid

(part # 355-001-002) with high

oxidation resistance and low

volatility. CAS # 63148-62-9.

Minimum Flash Point: 200°C

(392°F).

NOTE: Do not use bath fluids that will

decompose or volatilize producing flammable

vapors below the maximum instrument operating

temperature +25°C.

NOTE: Coloration of the Mineral or Silicon Bath

Oil is an indication that the Medium must be

changed. See Draining instructions in section

7.3 of this document. When a decision is made

to discard this material, dispose of this material

and its container to a hazardous of special

waste collection point. Country, State, or local

laws may impose additional regulatory

requirements regarding disposal. Dispose in

accordance to all applicable regulations.

WARNING: Bath oils contaminated with

light ends can pose a flammability hazard.

5.2 Power

Turn on the main power switch to the unit.

WARNING: Do NOT turn the power on

unless the bath is filled with the proper medium;

otherwise, damage may occur to the unit and

the warranty would be void.

5.3 Starting a Test

Before running a test, make sure the unit is

level. Otherwise, the results will be affected.

1. Insert the Pt-100 RTD probe into the holder

provided at the top of the bath. Insert the

RTD connector into the receptacle located

on the rear panel

2. Install the appropriate ASTM thermometer in

the cover plate of the bath using the holder

provided.

3. Set the desired operation temperature using

the temperature control (See Section 4.3).

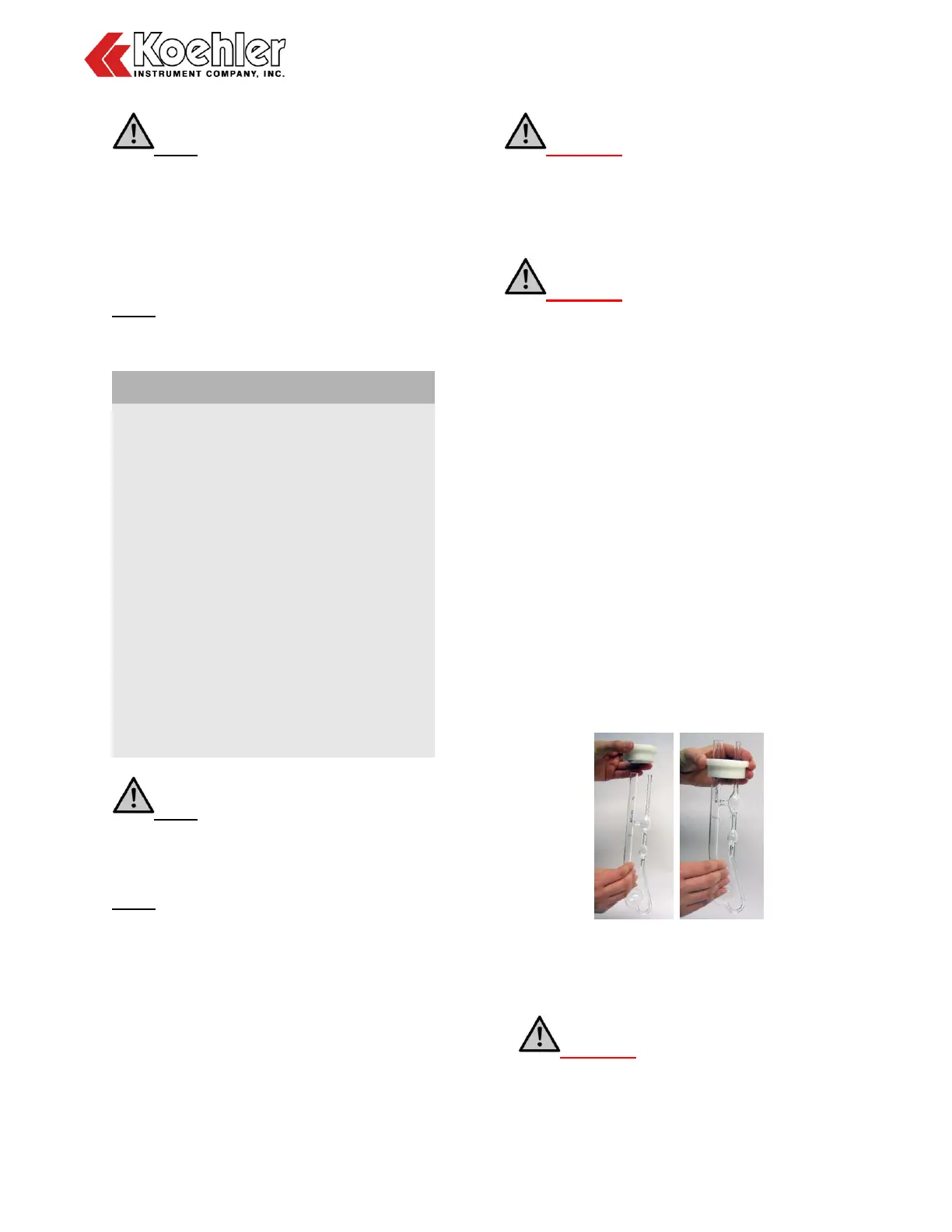

4. Install viscometer into its viscometer holder.

Carefully slide the holder onto the top of the

tube:

Figure 3

Charge the viscometer with sample and

carefully lower into the bath through the

viscometer ports.

WARNING: Do not test or run materials

that boil or exhibit high vapor pressure at the

bath test temperature.

Loading...

Loading...