KV3000 Kinematic Viscosity Bath

Operation and Instruction Manual

KV3000-Manual

-12-

3.3 Setup

Equipment Placement: Make sure the

instrument in placed on a firm, level table in an

area with adequate ventilation or in a hood. The

unit may be leveled by making minor turning

adjustments to the feet located at the base of

the unit. Please note that Koehler does not

supply a level with this equipment.

WARNING: Certain mechanical stresses

applied to the tempered glass front panel and

inner the inner borosilicate glass jar pose a

hazard to personnel. Impacts to these during

normal operation can shatter the glass

components releasing the bath fluid posing

thermal burn hazards and slipping hazards. For

this reason the instrument must be operated by

and accessible only to trained and authorized

personnel and located in an area where this type

of impact is likely to occur.

Environmental Conditions: The instrument

environment must comply with the following

conditions for proper setup:

No / Low Dust

No direct sunlight

Not near heating or AC ventilation ducts

No Vibrations

Clearance from other instruments

Temperature Range: 5 to 40°C

Elevation to 2000 meters

Relative Humidity: < 80%

Ventilation. A fume hood or exhaust system is

required when operating the unit. Flammable

vapors and/or steam are generated during

operation and must not be permitted to

accumulate. A canopy-style hood may be used if

the height from the top of the unit to the canopy

is 5 feet or less. The exhaust blower should

have a rating of 1000 C.F.M. or greater.

Power: Connect the line cords to properly fused

and grounded receptacles with the correct

voltage as indicated in section 1.3 or on the

back of the unit.

WARNING: For safety, disconnect the

power when performing any maintenance and/or

cleaning. Do NOT turn the power on unless the

bath is filled with the proper medium; otherwise,

damage may occur to the unit and the warranty

will be void.

4 Descriptions

4.1 Instrument Controls

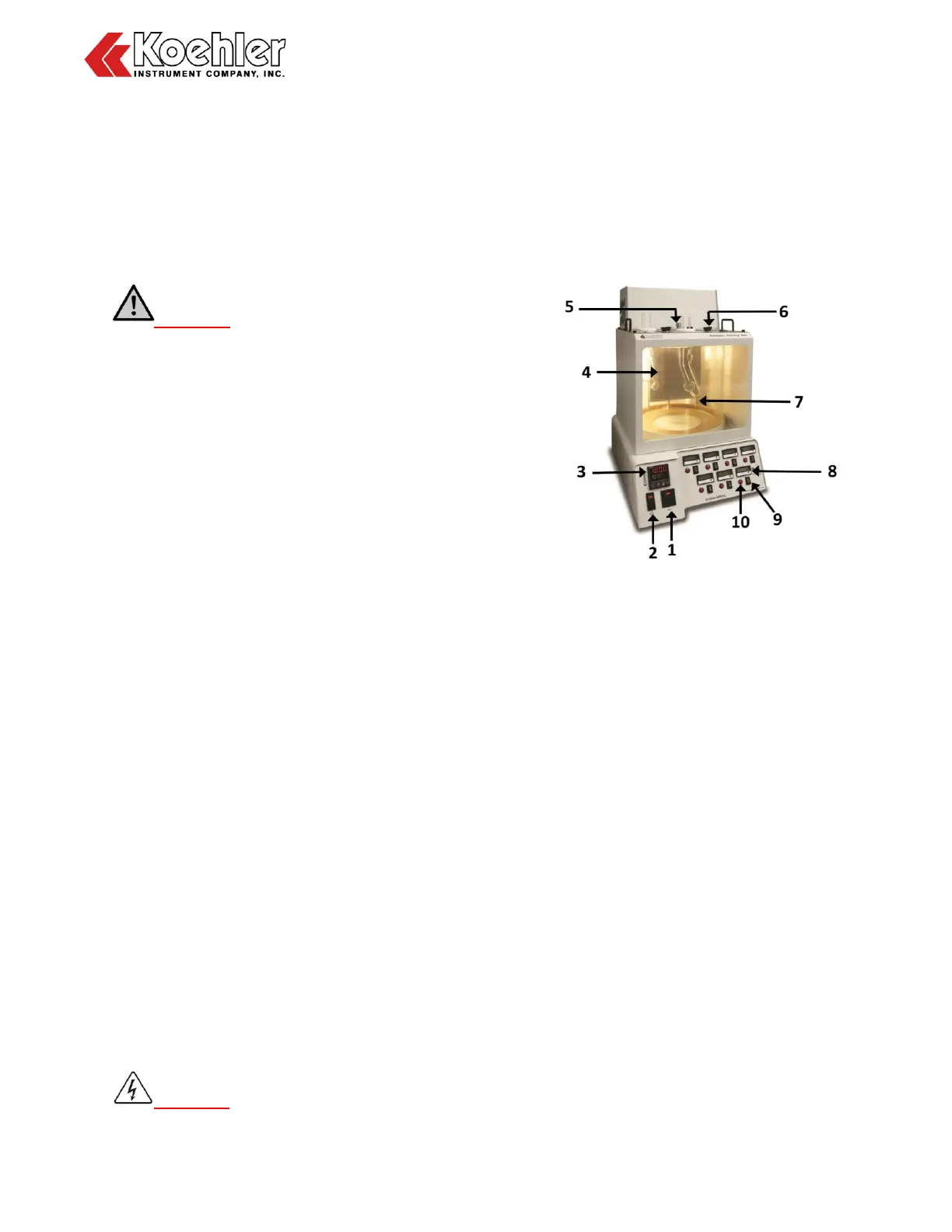

Figure 1: Instrument Descriptions

1. Power Switch. This switch controls the

power to the entire unit. When the

power switch is in the ON position, the

digital temperature controller, and the

stirrer are powered on.

2. Lamp Switch. This switch controls

turning ON/OFF the lamp for illuminating

the test samples.

3. Temperature Controller. The

temperature controller regulates the

bath temperature for the test procedure.

Refer to Section 4.3 for full operational

details.

4. Temperature Regulation: The heater

coils stabilize the bath temperature to

desired setting within ± 0.02°C. Running

coolant through the cooling coils allows

bath to maintain temperatures near or

below ambient.

5. Thermometer/Thermocouple Port:

This port allows for independent

temperature measurement of the bath

temperature with a thermometer or a Pt-

100 RTD probe for precise temperature

measurements and digital temperature

Loading...

Loading...