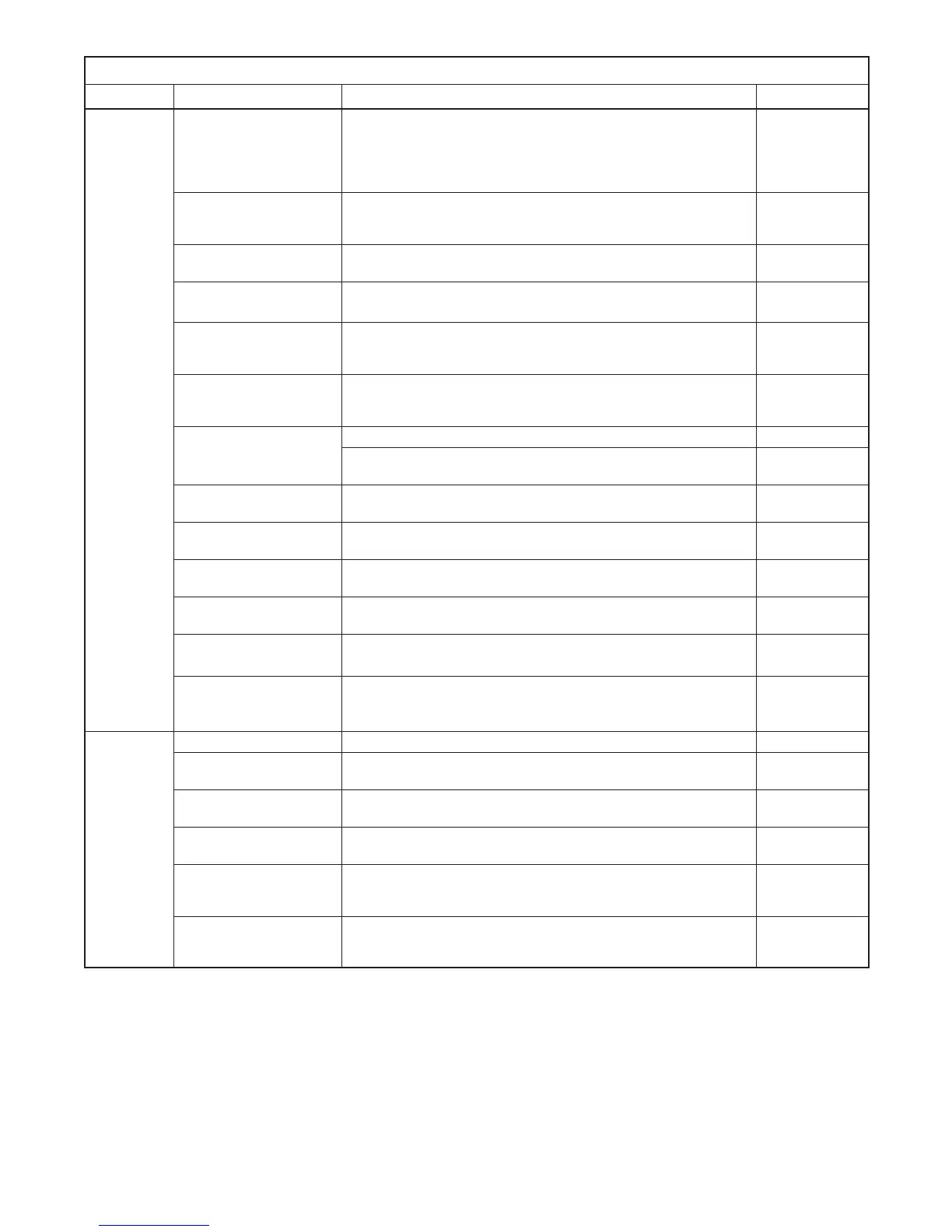

TP-6196 10/0932 Section 3 Troubleshooting

Troubleshoot in g Chart, continu ed

Problem ReferenceCorrective ActionPossible Cause

No output

voltage

AC output circuit breaker

open

Check for AC voltage on the generator side of circuit breaker. If

there is AC voltage on the generator side of the breaker, then a

problem i n the load circuits is causing the line circuit breaker to

trip. Check for and correct short circuits or overloading on the

load side before resetting the circuit breaker.

—

Alternator or control

system

Perform separate excitation procedure to isolate the problem to

the alt ernator or the control system. Then troubleshoot the

alternator or control system components as follows.

Section 6.2

Aux. winding fuse F1

blown.

Check fuse F1 and replace if blown. If fuse blows again, check

stator.

Section 6.3

SCR modul e Check auxiliary winding fuse F1.

Replace SCR module and test voltage.

Section 6.13

Section 6.8

Controller Check controller settings. Check wiring and connections.

Before replacing controller, replace SCR module and check

voltage.

Section 4.5 or .

Section 6.8

Open wiring, terminal, or

pin i n buildup circuit or

SCR modul e circuit

Check continui ty. Sections 6.13

Section 8

Brushes

Inspect brushes and replace if worn. Section 6.6

Check for brushes sticking in brush holder or broken brush

spring.

Section 6.6

Rotor connections Check for open circuit in rotor connection circuit (leads FN and

FP to SCR and RIB).

Section 8

Rotor slip rings dirty or

corroded

Check sli p ring condition. Section 6.4

Rotor (open, grounded,

or shorted windings)

Check volt age and c ontinuit y. Section 6.4

Stator (open, grounded,

or shorted windings)

Check volt age and c ontinuit y. Section 6.3

Flash relay (K3) on RIB

(ADC 2100)

Check fl ash LED on RIB.

Check fuse F2 and troubleshoot RIB.

Section 4.8

Flash relay (K3) on

controller board

(ADC-RES)

Check fuse F2.

Check flash LED1 on controller board. If LED1 indicates power

to K3 but relay does not operate, replace controller circuit board.

Section 5.7

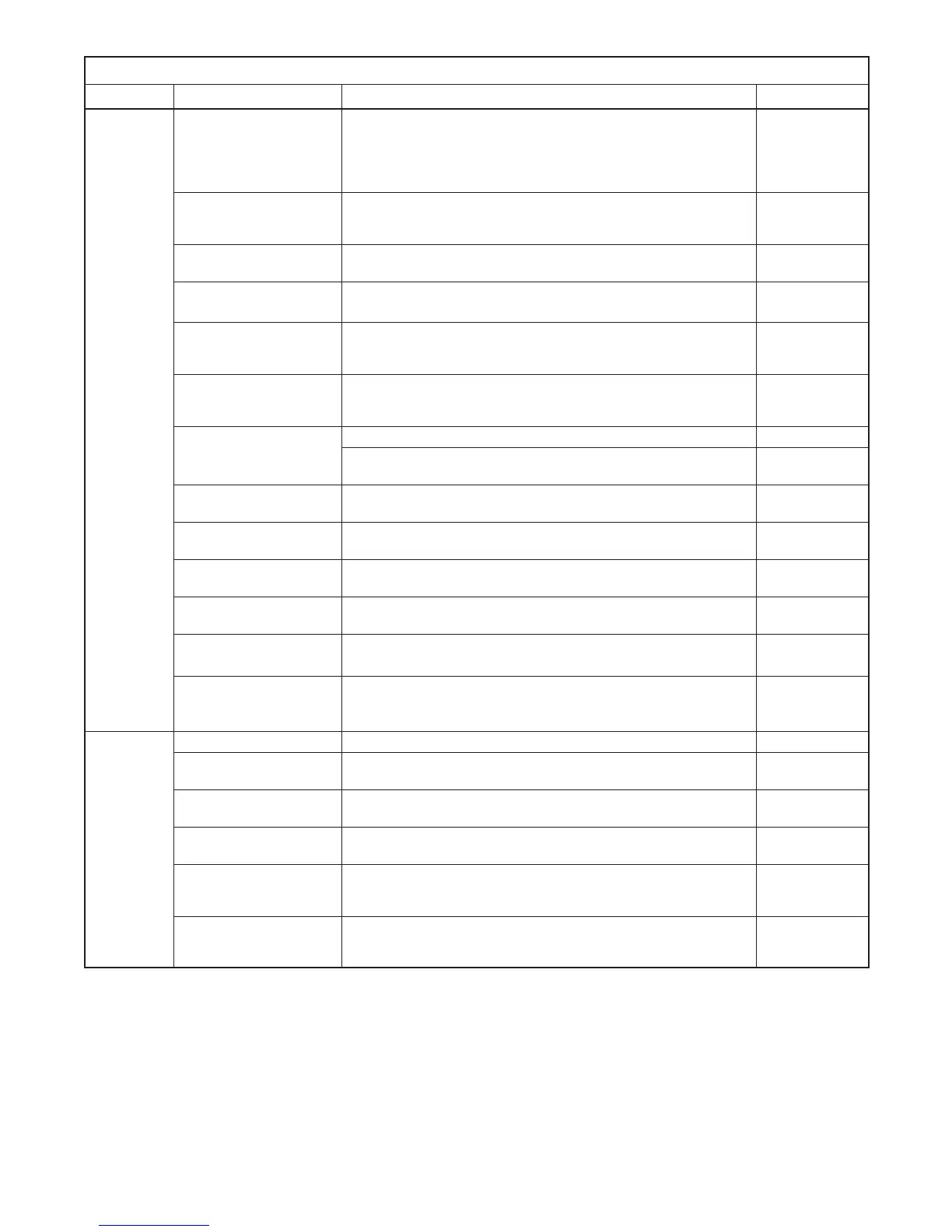

Noisy

operation

Exhaust system leaks Check and replace as necessary. Section 2.6

Engine not running

smoothly

See Generator set operates erratically in this table. —

Broken or damaged

vibromount(s)

Check and replace as necessary. Section 7

Loose or vibrating sheet

metal/housing

Retighten screws, replace rivets.

—

Exhaust piping or air

inlets/outlets not

securely i nstall ed

Inspect f or loose parts and secure if necessary. Section 2.6

Excessive

engine/generator

vibration

Check, rotor, crankshaft, bearing, etc. (disassembly of engine

and/or alternator may be required).

Section 7

Engine S/M

Loading...

Loading...