TP-5964 7/0110 Section 3 Scheduled Maintenance

3.4 Fuel System

3.4.1 Fuel Specifications

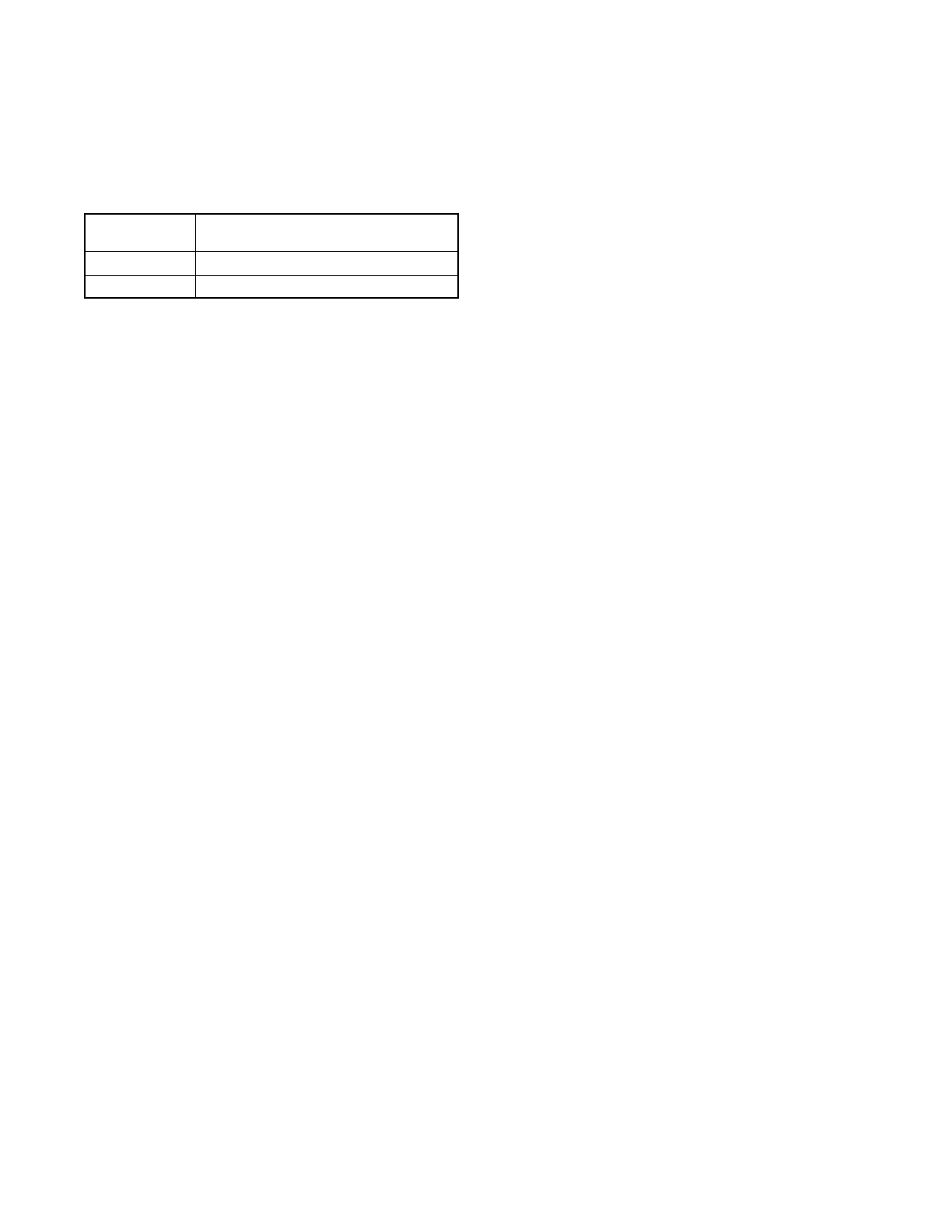

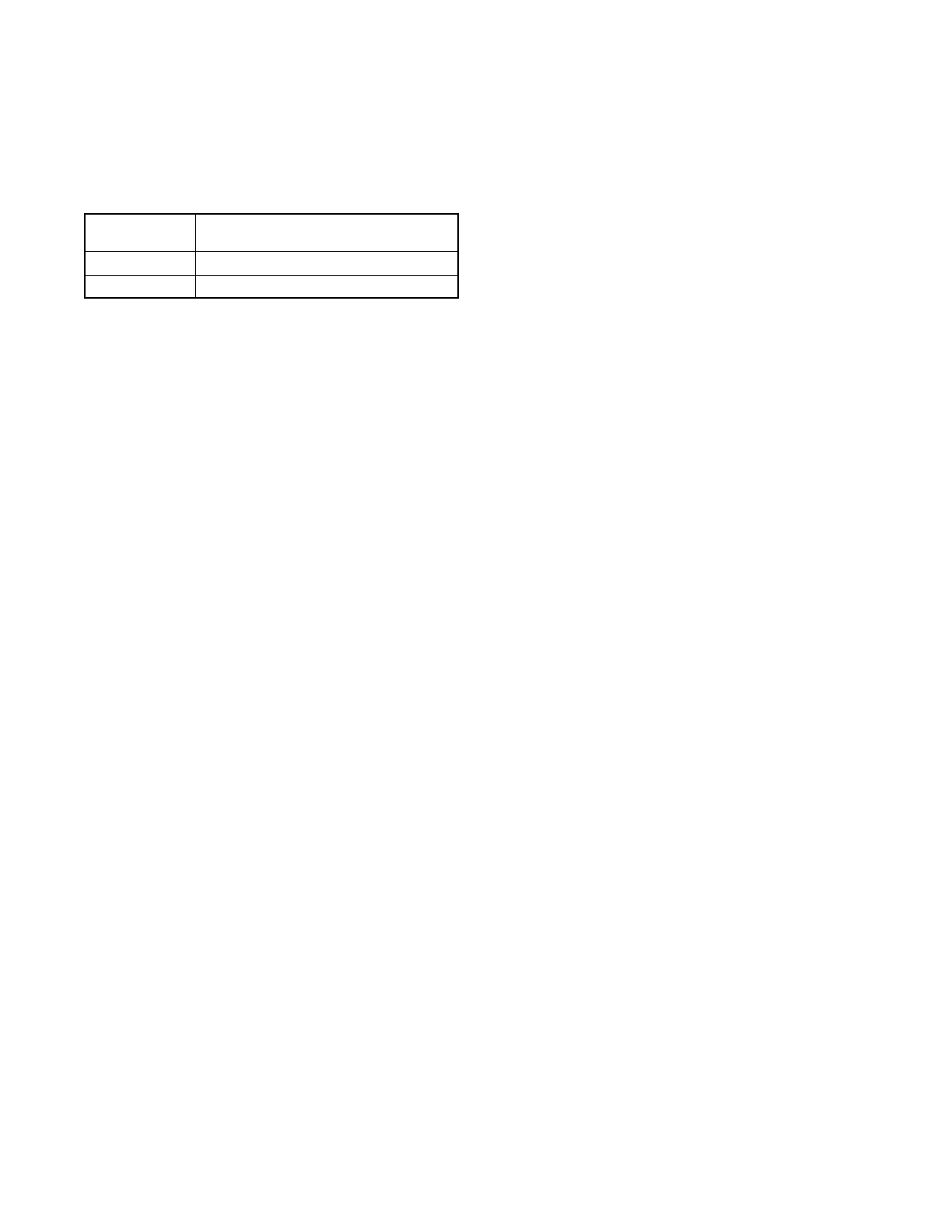

Use a clean, good quality diesel fuel oil with a cetane

number of 45 or greater. Clean fuel prevents diesel fuel

injectors and pumps from clogging. See Figure 3-4.

United States ISO 8217 DMA, BS 2869 Part 1 Class A1

or Part 2 Class A2

United Kingdom BS 2869-1983, Part 2 Class A2

Germany DIN 51 601-1978

Figure 3-4 Fuel Recommendations

Note: Never store diesel fuel in galvanized containers;

diesel fuel and the galvanized coating react

chemically to produce flaking that quickly clogs

filters or causes fuel pump or injector failure.

Note: Avoid storing fuel for more than one month. Take

special precautions to keep all dirt, water, and

other contaminants out of fuel to prevent the

growth of microbes. Microbes form slime, which

clogs the fuel filter and lines.

Note: Do not run the generator set out of fuel because

the fuel lines will draw in air. If the fuel lines draw

in air, bleed the fuel system before restarting the

unit.

3.4.2 Fuel Filter

The quality and condition of the fuel largely determine

the filter’s useful life. Do not clean the paper filter

element. Replace the fuel filter according to the service

schedule. Section 1 shows the fuel filter location. Use

the procedure below to replace the fuel filter.

Fuel Filter Replacement Procedure

1. Close the fuel supply valve.

2. Loosen the fuel filter by turning it counterclockwise.

Remove the fuel filter and use rags to clean up

spilled fuel oil. Dispose of the fuel filter in an

approved manner.

3. Clean the c ontact surface of the fuel oil filter

adapter.

4. Lightly lubricate the gasket surface of the new fuel

filter with fresh fuel oil. Thread the filter on the

adapter until the gasket makes contact;

hand-tighten an additional one-half turn. Wash

hands after any contact with fuel oil.

5. Open the fuel supply valve.

6. Bleed the system using information from

Section 3.4.3.

Loading...

Loading...