TP-6862 6/1414 Section 3 Cooling System

Do not use a speed scoop or cup design intake

through-hull strainer because it can cause a ramming

effect and force water upward, past the seawater pump,

and into the engine cylinders when the vessel is moving

and the generator set is shut down.

Do not use hull designs incorporating sea chests or

other designs that provide a positive pressure to the raw

water pump for the intake through-hull strainers.

Positive pressure forces water past the raw water pump

and into the engine. A sea chest is a concave

molded-in-the-hull chamber that aligns to the direction

of travel. A sea chest configuration applies a positive

pressure similar to a scoop-type through-hull strainer.

3.2.2 Seacock

Mount the seacock to the hull, assemble it to the intake,

and ensure that it is accessible for operation. Figure 3-2

shows a typical installation.

Avoid overcaulking the seacock. Excess caulk reduces

water flow and, in some cases, develops a barrier that

can force water upward, past the seawater pump, and

into the engine cylinders when the vessel is moving and

the generator set is shut down.

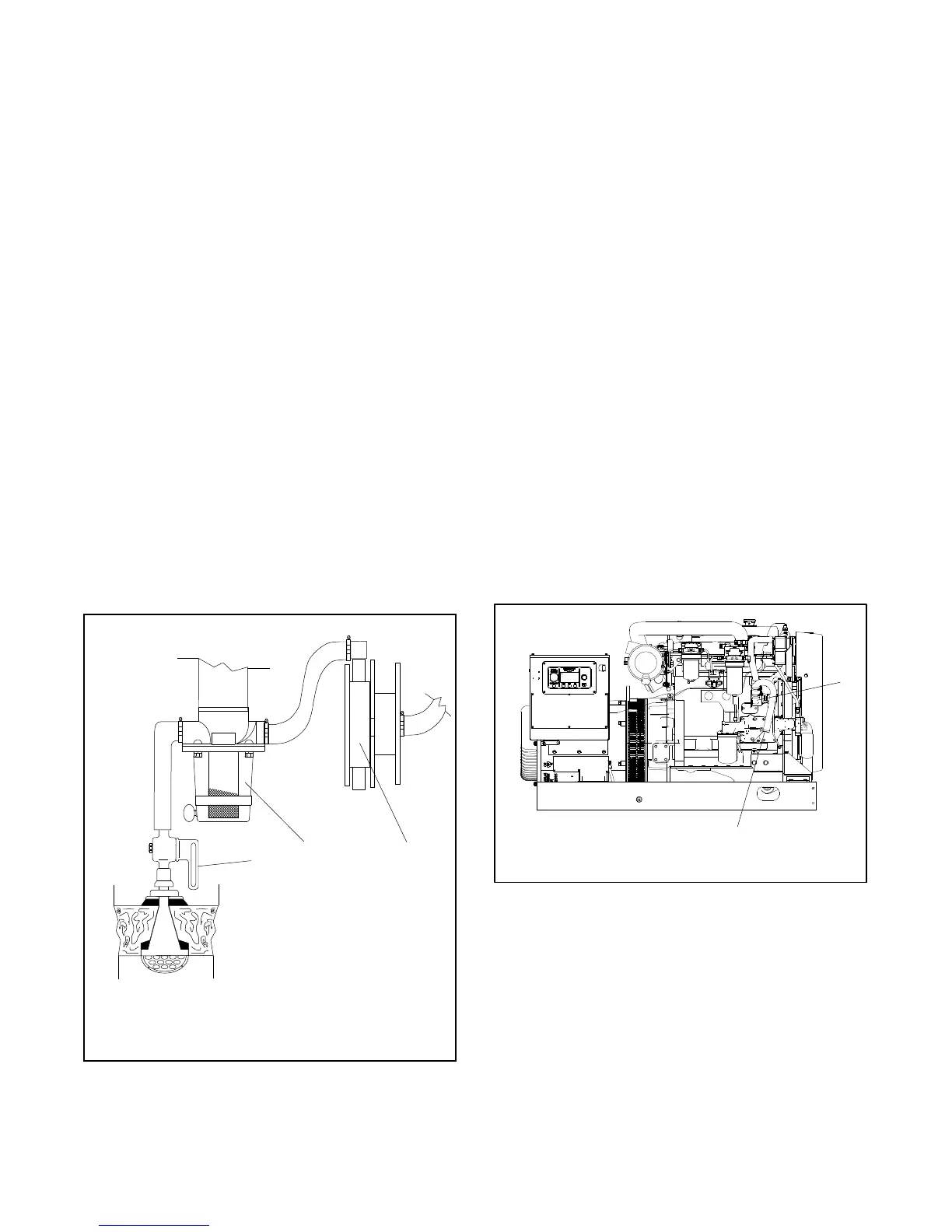

3.2.3 Seawater Strainer

123

5982--3.3

1. Seawater pump

2. Seawater strainer

3. Seacock

Figure 3-4 Seawater Strainer

Mount the seawater strainer to the seacock or

permanent structure at a point not higher than the

seawater pump. Ensure that the strainer is accessible

for service. See Figure 3-4 for a typical installation.

Some seawater strainers include a seacock and an

intake through-hull strainer.

Maximum seawater inlet p ressure at the seawater pump

is 34.5 kPa (5 psi). Excessive pressure will cause water

ingestion.

3.2.4 Water Lines

Water lines from the seacock to the engine-driven

seawater pump are usually constructed of flexible hose.

Connect a flexible section of hose to the seawater pump

to allow for vibrational motion of the generator set during

operation. Support a nonflexible water line within

102 mm (4 in.) of its connection to the flexible section.

Keep the seawater hose as straight and short as

possible. If the hose is too long, usually over 4.6 m

(15 ft.), water suction problems may occur. See

Section 7 for the inlet water line hose size and the

seawater connection to the seawater pump inlet. Avoid

running the inlet pipe above the generator. See

Figure 3-5 for the seawater inlet connection.

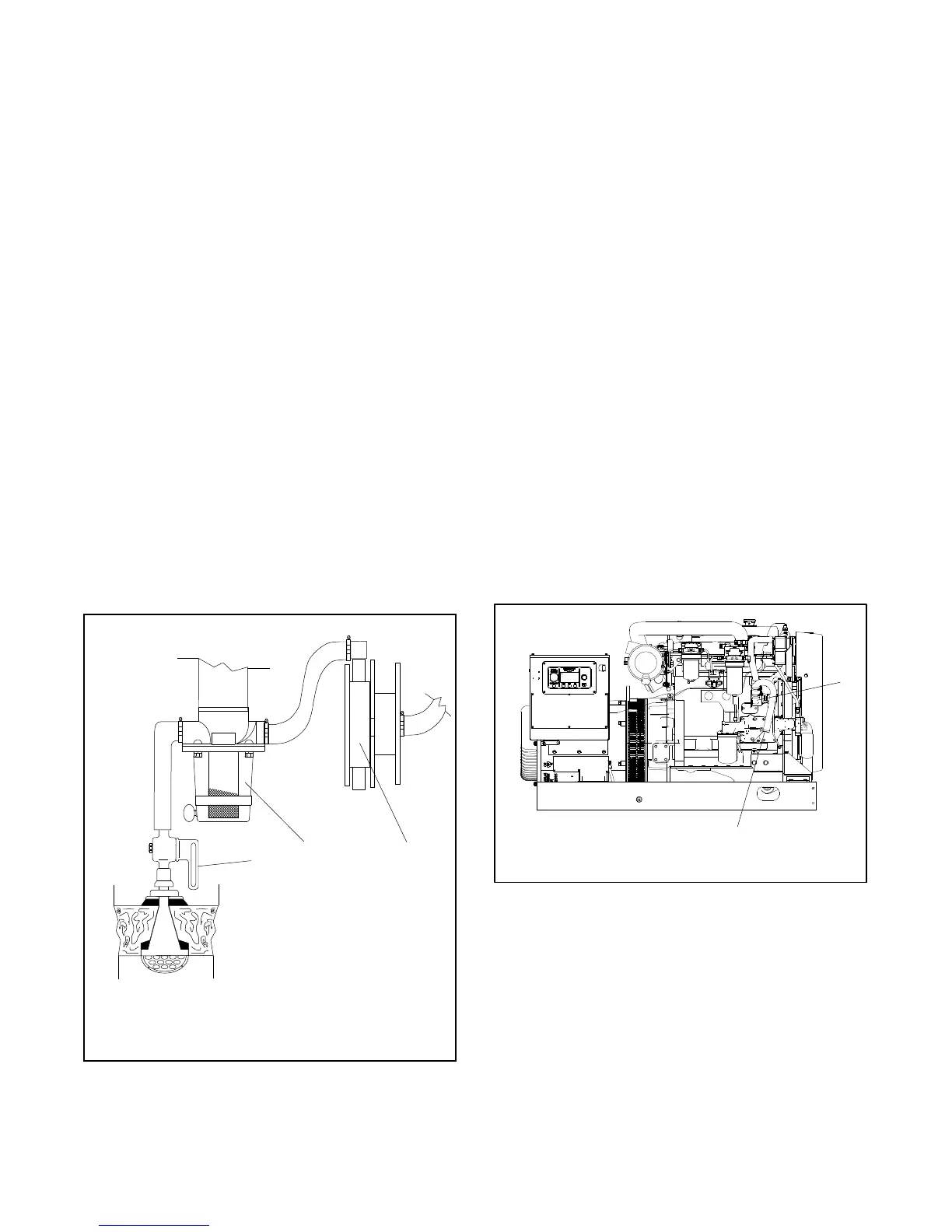

1

ADV8500A-

1. Seawater pump

2. Seawater inlet (opposite s ide)

2

Figure 3-5 Seawater Inlet Connection (Located on

non-service side), Typical

3.2.5 Closed Heat Exchanger

A closed heat exchanger is the best cooling method for

most applications. See Figure 3-6 for a typical

installation. Provide space to access the water-cooled

exhaust manifold pressure cap.

Loading...

Loading...