103

Reassembly

62 690 13 Rev. A KohlerEngines.com

Install Oil Filter and Add Oil to Crankcase

NOTE: Make sure both oil drain plugs are installed and

torqued to 21.4 N·m (16 ft. lb.) to prevent oil

leakage.

1. Install oil drain plugs. Torque plugs to 21.4 N·m

(16 ft. lb.).

2. Place new fi lter in shallow pan with open end up. Fill

with new oil until oil reaches bottom of threads. Allow

2 minutes for oil to be absorbed by fi lter material.

3. Apply a thin fi lm of clean oil to rubber gasket on new

fi lter.

4. Refer to instructions on oil fi lter for proper

installation.

5. Fill crankcase with new oil. Level should be at top of

indicator on dipstick.

6. Reinstall oil fi ll cap/plug and dipstick and tighten

securely.

Connect Spark Plug Leads

Connect leads to spark plugs.

Prepare Engine for Operation

NOTE: If ECU, throttle body, TPS or fuel pump module

were replaced, an ECU Reset and TPS Learn is

required. Refer to EFI System Reset and TPS

Learn procedure.

Engine is now completely reassembled. Before starting

or operating engine, be sure to follow steps below.

1. Make sure all hardware is tightened securely.

2. Make sure oil drain plugs, Oil Sentry

™

pressure

switch, and a new oil fi lter are installed.

3. Verify crankcase has been fi lled with correct amount,

weight, and type of oil. Refer to oil recommendations

and procedures in Maintenance, Specifi cations, and

Lubrication System.

4. Turn on fuel supply.

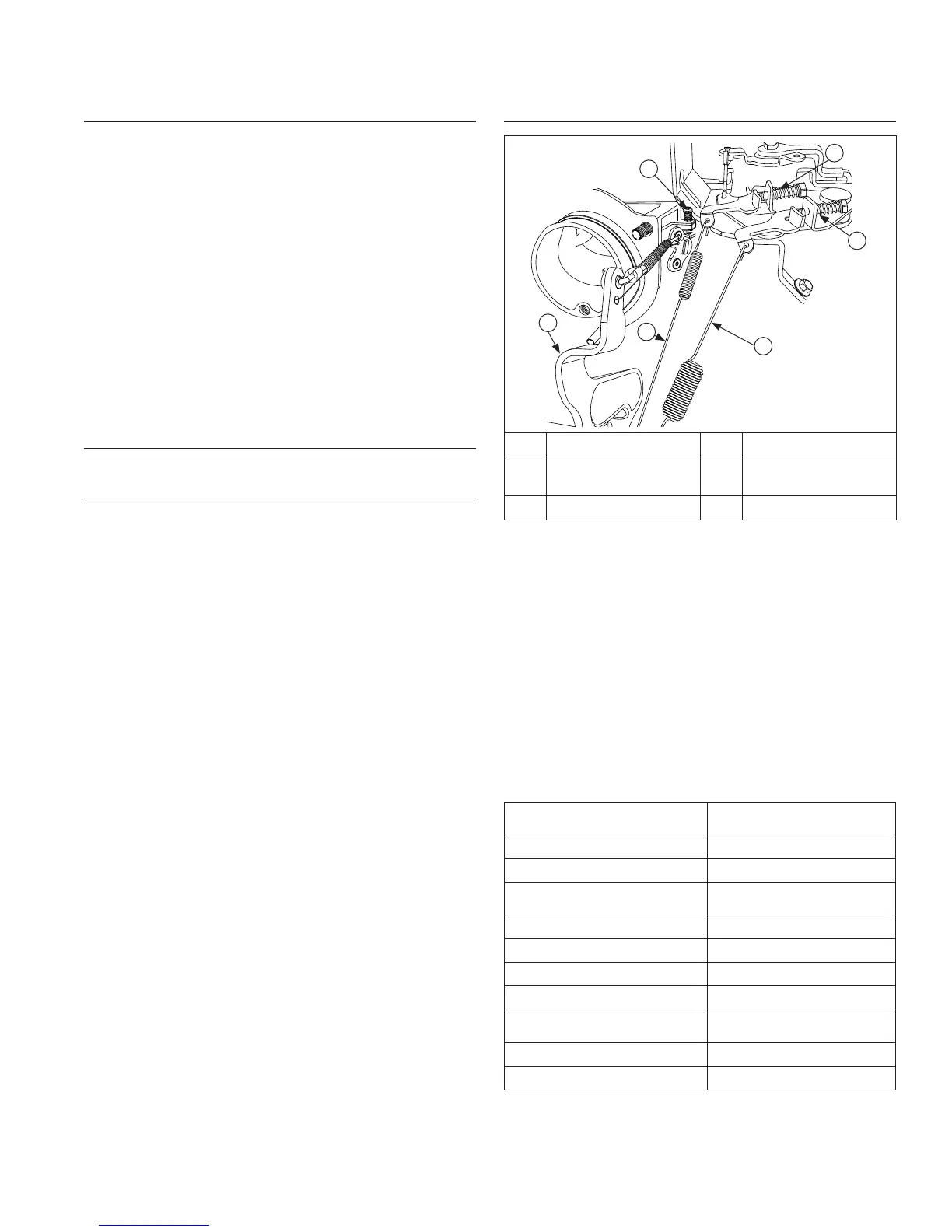

Testing Engine and Setting Speed

B

C

F

A

E

D

A Idle Speed Screw B High Speed Screw

C

Governed Low

Idle Screw

D

Governed Idle

Spring

E Governor Spring F Governor Lever

It is recommended engine be operated on a stand or

bench prior to installation in piece of equipment.

1. Set engine up on a test stand. Install an oil pressure

gauge. Start engine and check to be certain oil

pressure (20 psi or more) is present. Run engine at

idle for 2-3 minutes, then 5-6 minutes more between

idle and midrange.

2. Adjust idle speed screw located on throttle body 100

RPM below specifi ed idle speed setting.

3. Set governed idle speed to specifi ed governor speed

setting.

4. Adjust high speed as necessary. Make sure

maximum engine speed does not exceed 3750 RPM

(no load).

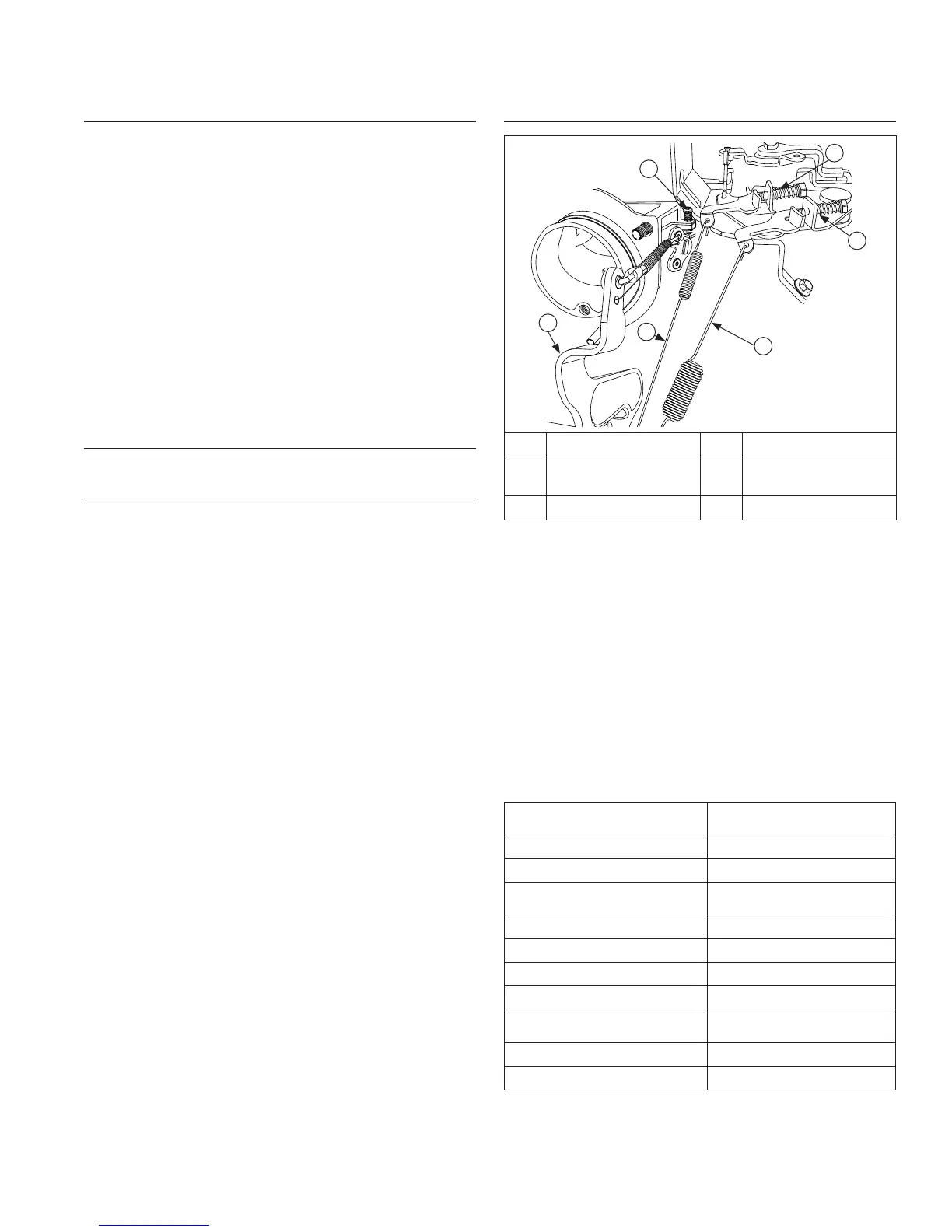

Governor Spring/RPM Range Chart

ECH940/ECH980

Governor Idle Spring (Color) Idle Speed (RPM)

Black 1626-1800 RPM

ECH940

Governor Spring (Color) High Speed (RPM)

Orange 3000-3300 RPM

Brown Patch 3301-3675 RPM

Red 3676-3900 RPM

ECH980

Governor Spring (Color) High Speed (RPM)

Purple 3000-3900 RPM

Loading...

Loading...