REASSEMBLY

The following sequence is suggested for reassembling engine after components have been recon

-

ditioned and all sub

-

assembly work, such as reinstalling bearings, guides, bushings, etc., has been

completed. The procedure may be varied slightly to accommodate special equipment used on certain

engines. Also the procedure varies in certain areas because of design differences between the various

rnodels--these differences are called out where the sequence is affected.

STEP 1

-

Tappets: Lightl

y

coat outside of tappets with oil, then insert in tappet bore.

All four tap

-

-

pets are identical and are therefore interchangeable between intake and exhaust and between

the cylinder banks if new tappets are used.

If

old tappets are used, install in same position

as removed (noted in Disassembly Section).

STEP

2

-

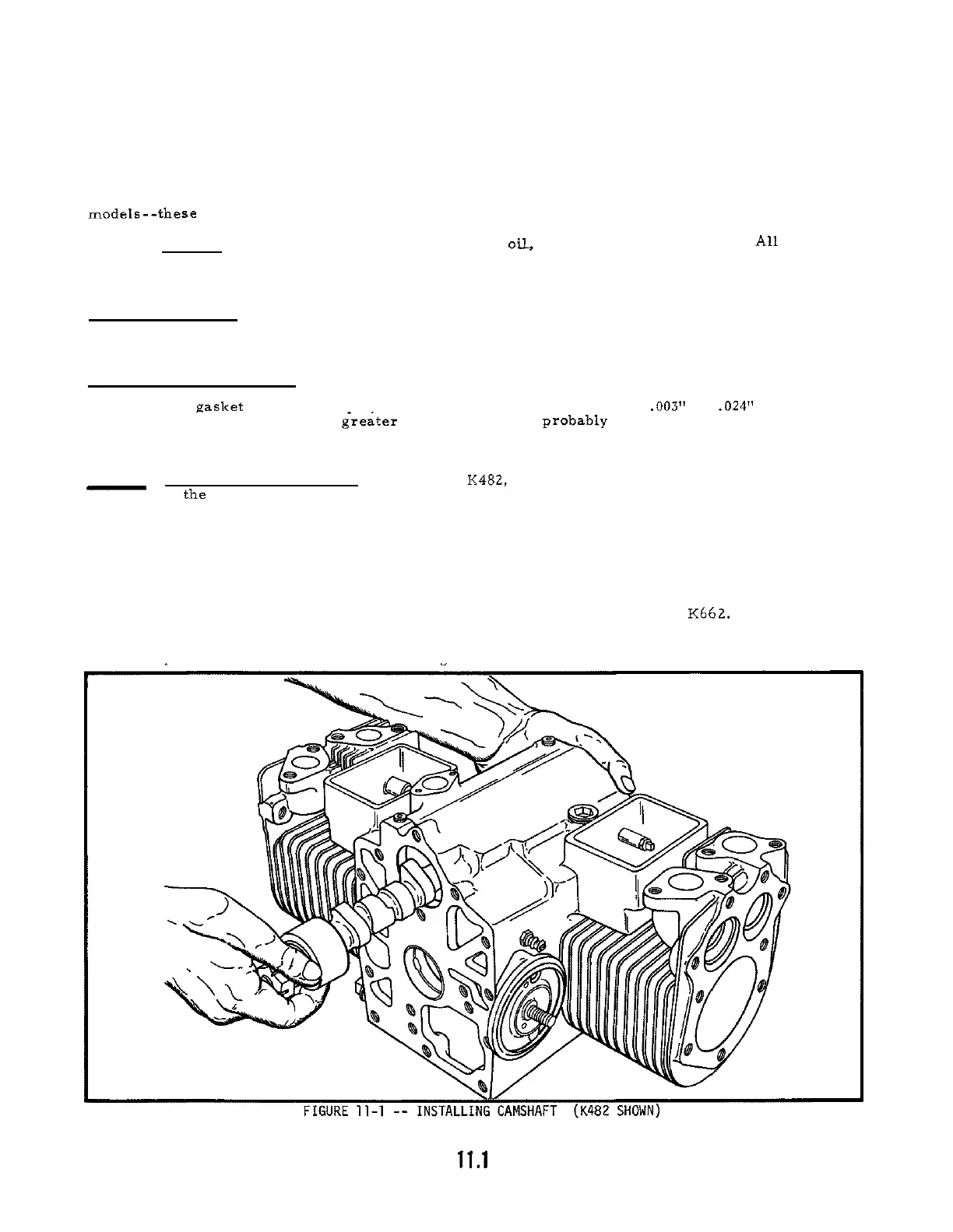

Camshaft:

Check to make sure oil hole in camshaft sleeve bearing lines up with crankcase

porting,

lubricate camshaft and bearings, then carefully guide camshaft through bearings

(front end first) and into position in block.

Install welch plug at rear end of camshaft if this

has been removed.

STEP

3

-

Gear Cover Plate: Position new gasket, then install gear cover plate and secure to block at

four points (three points on model

K662

en

g

ines) around the camshaft opening.

This

plate

and

gasket controls end play of camshaft which should be in the

,003"

to

.024"

range on all

models.

If end play is

beater than this, plate is ~robahl~ worn excessively in camshaft con

-

tact area and must therefore be replaced.

Before installing, grease plate around camshaft

contact area to prevent seizure during initial start up.

STEP

4

-

Crankshaft

-

Closure Plate: While some

K482. K532

models use sleeve bearings at both ends

-

of the crankshaft, other models have a sleeve hearing at the front and a ball bearing at the

rear or closure plate end.

On

the models with the ball bearing, the closure plate must be

assembled to the crankshaft as per instructions in the Reconditioning Section before the crank

-

shaft is installed in the block.

On

this type, the ball bearing is locked in position and this

controls crankshaft end play.

If the retaining rings, grooves and bearing are in good shape,

the end play should be within limits.

K662

engines use tapered roller bearings and have oil

transfer sleeves. Crankshaft end play is controlled by thickness of the gaskets used between

the closure plate and block. The procedure for adjusting and checking crankshaft end play

differs between the

K482

or

K532

with sleeve bearings and the model

K662.

The following

assembly and end play checking procedure assumes that the sleeve bearings, oil transfer

sleeves, hearing races and bearings have been pressed into the block or on the crankshaft

per instructions in the Reconditioning Section.

Loading...

Loading...