TP-6903 5/16a Fuel System Troubleshooting 49

3.3. No Start

Definition: The engine cranks but does not start.

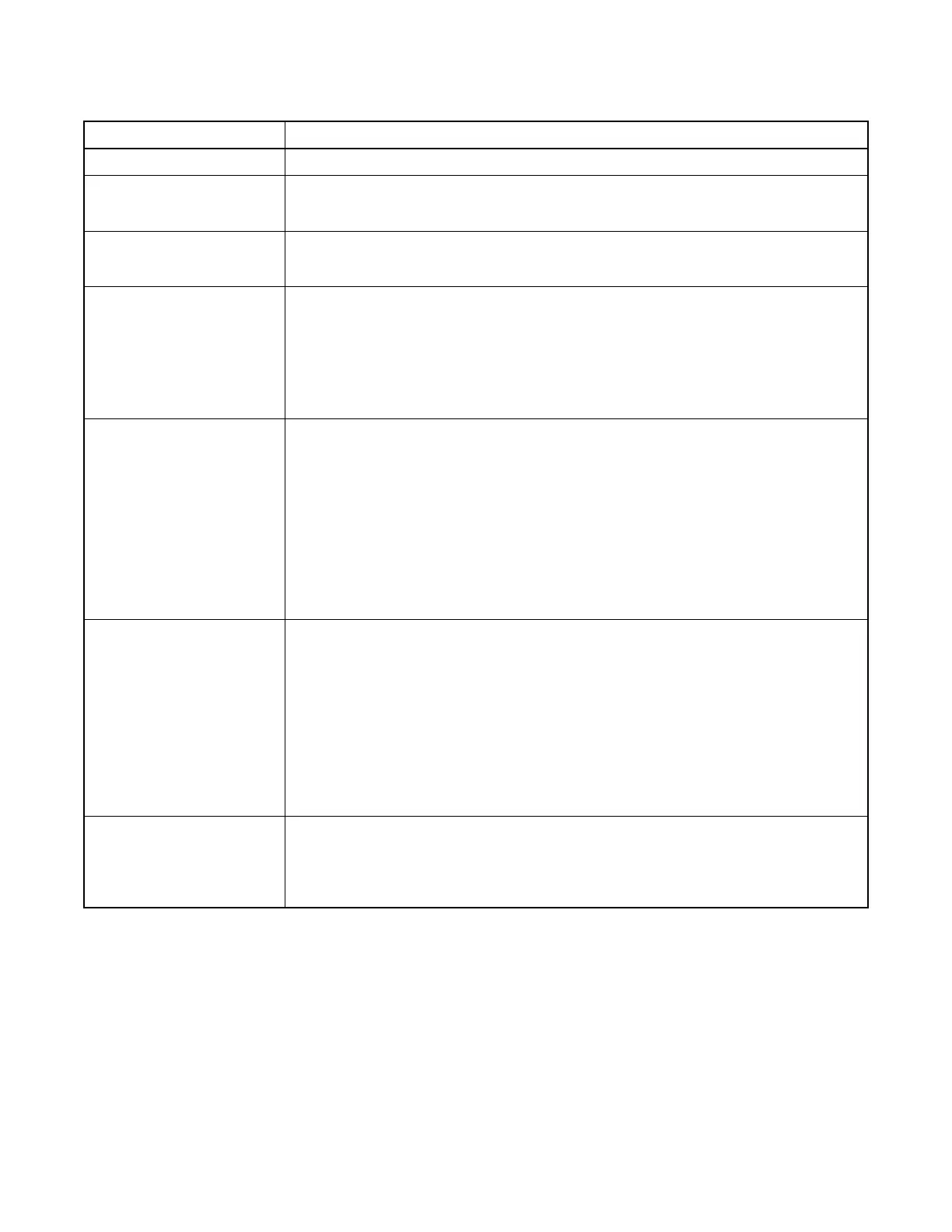

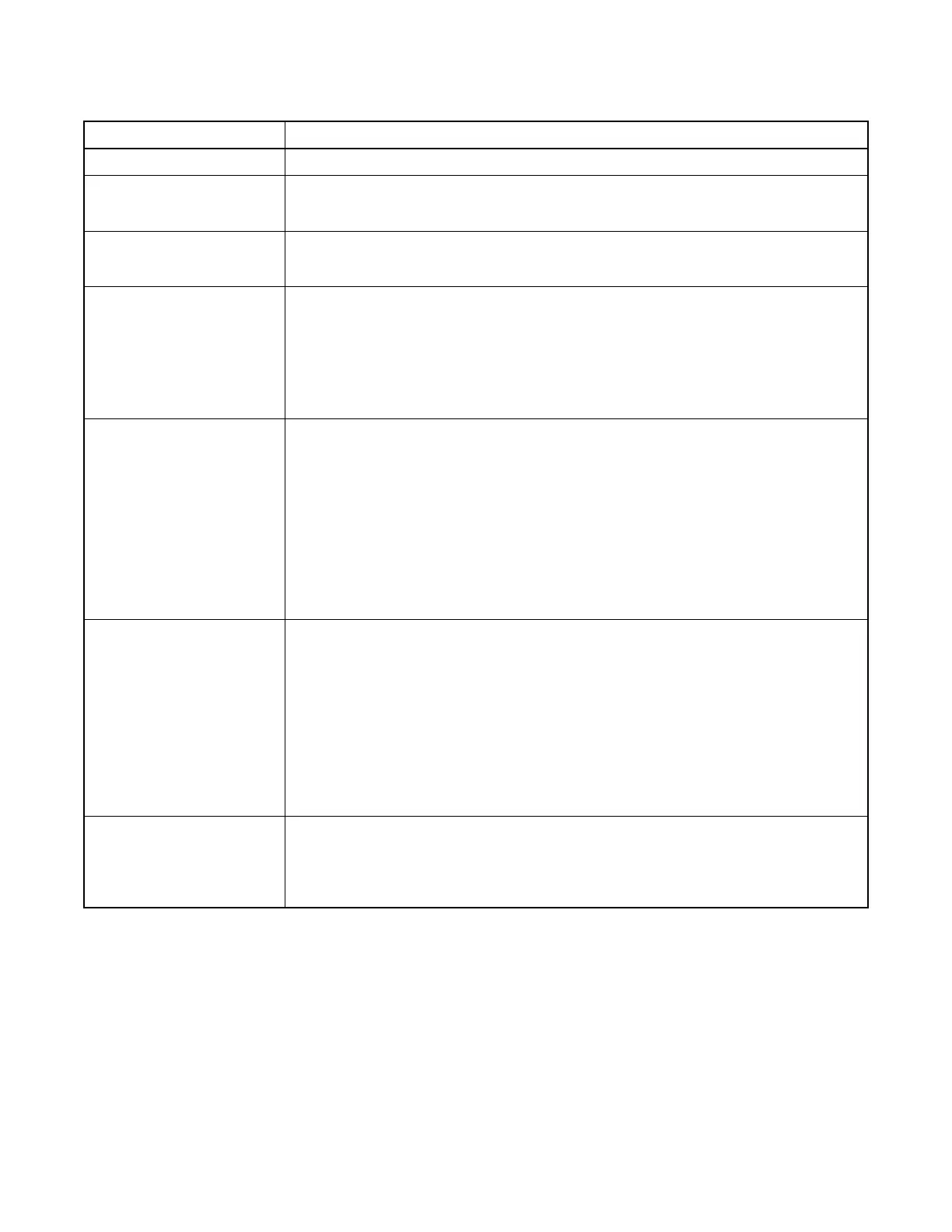

Figure 3-5 No Start Troubleshooting

Checks Action

Preliminary Checks None

ECM Checks

Use Spectrum to :

o Check for proper communication with the ECM

o Check battery power, ignition power and ground circuits to the ECM.

Sensor Checks

Check the TMAP sensor.

Check the crankshaft position sensor for output (rpm). This can be verified by an RPM

signal on Spectrum.

Fuel System Checks

Note: A closed gas supply valve will create a no start condition.

Verify proper operation of the shut-off solenoid valves.

Check for air intake system leakage around the fuel pressure regulator, air-fuel mixer

and throttle body.

Check for air intake system leakage at all connections between the air-fuel mixer and

throttle body on turbocharged engines.

Check the fuel system pressures.

Ignition System Checks

Check for the proper ignition voltage output.

Verify that the spark plugs are correct.

Check the spark plugs for the following conditions:

o Wet plugs (oil fouling)

o Cracks.

o Wear.

o Improper gap.

o Burned electrodes.

o Heavy deposits.

Check for bare or shorted ignition leads.

Check for loose ignition coil connections at the coil.

Engine Mechanical Checks

Check for the following:

o Manifold vacuum leaks.

o Air-fuel mixer vacuum leaks.

o Charge air cooler leaks on turbocharged engines.

o Engine vacuum leaks.

o Improper valve timing.1

o Low compression.

o Improper valve clearance.

o Worn rocker arms.

o Broken or weak valve springs.

o Worn camshaft lobes.

Exhaust System Checks

Check the exhaust system for a possible restriction:

o Inspect the exhaust system for damaged or collapsed pipes.

o Inspect the muffler for signs of heat distress or for possible internal failure.

Check that the turbocharger turbine and compressor blades do not rub or bind against

the turbocharger housing.

Loading...

Loading...