TP-6903 5/16a Fuel System Overview 11

Section 1 Fuel System Overview

1.1. Introduction

The KG2204 and KG2204T are four-stroke internal

combustion engines certified to operate on Natural Gas

(NG) or Liquefied Petroleum Gas (LPG). System

configuration is factory preset for NG and can be reset

for LPG applications.

At startup, the engine ECM operates in an open-loop

fuel state, which means fuel delivery is based on a fuel

calibration program internal to the ECM. The program

controls the fuel control valve to achieve stoichiometric

combustion.

After the oxygen sensor heats up and the engine

coolant temperature reaches a predetermined level,

the ECM calibration program transitions to a closed-

loop mode. The air/fuel delivery is based on the

oxygen sensor input and engine sensor data. The

engine ECM uses this data to regulate the fuel control

valve (FCV), which is used as a fuel trim device and is

located at the intake manifold. The FCV is an

electrically controlled engine vacuum switch. When

the FCV is energized, the valve opens and, through a

vacuum line connection to the fuel regulator, creates a

vacuum on the fuel pressure regulator. This vacuum

causes the regulator’s diaphragm to close, decreasing

the fuel delivered to the intake. The FCV signal would

be considered a modulated signal sent by the ECM to

obtain stoichiometric combustion.

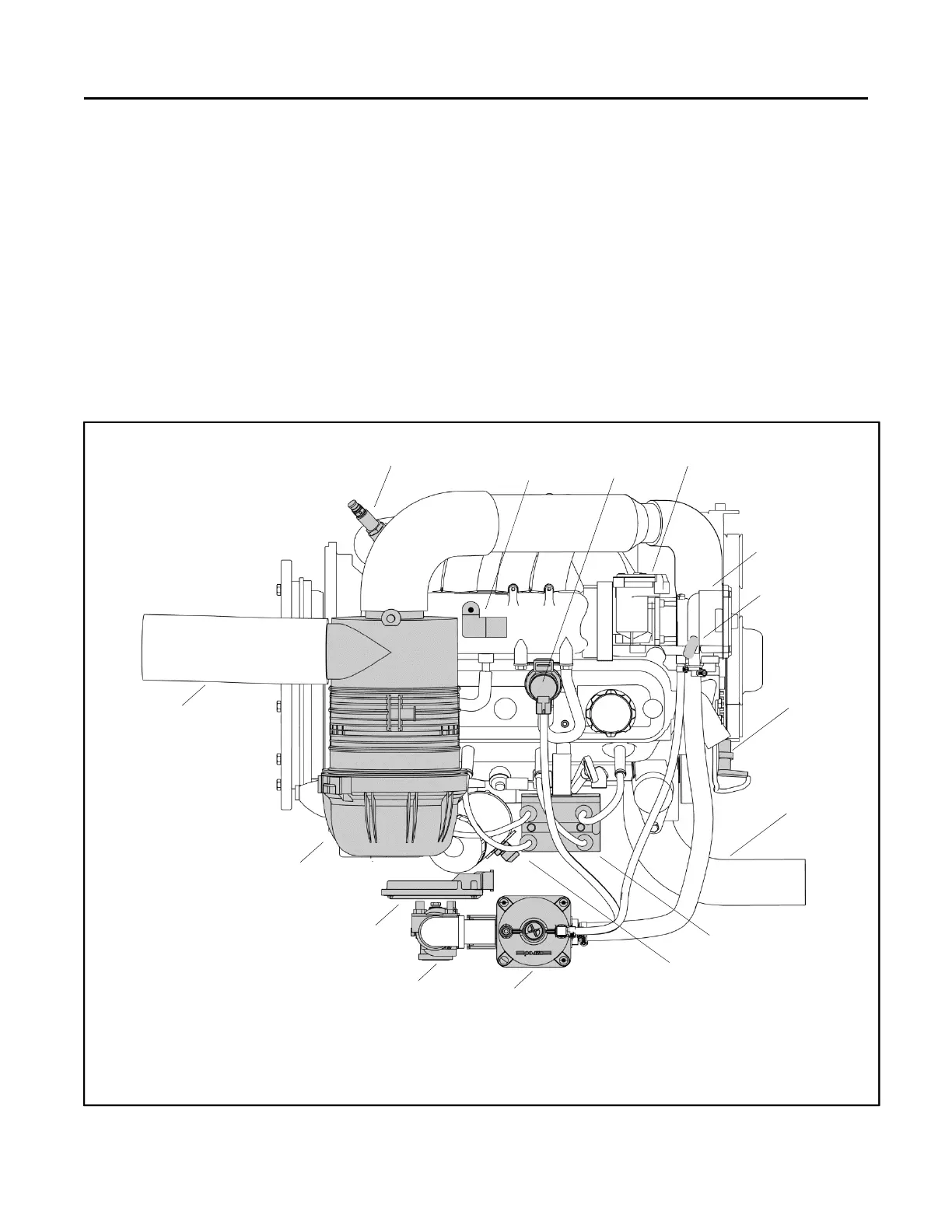

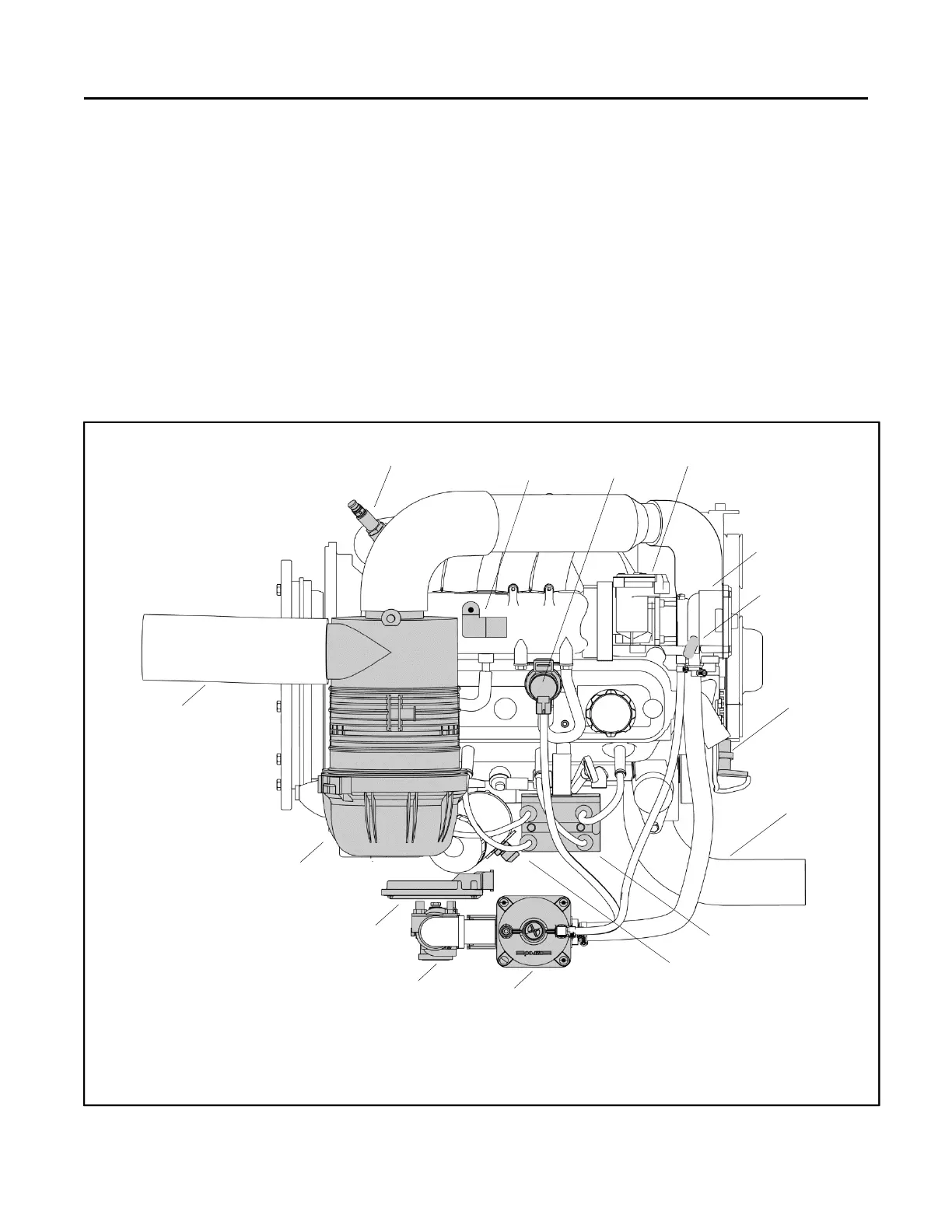

Figure 1-1 Fuel System Overview, KG2204 Naturally Aspirated Engine

1. HEGO sensor

2. TMAP sensor

3. Fuel control valve

4. Throttle body

5. Air-fuel mixer

6. Coolant temperature sensor

7. Crankshaft position sensor

8. Exhaust

9. Ignition coil

10. Oil pressure sender

11. Fuel pressure regulator

12. Fuel shut-off valve

13. ECM

14. Air cleaner

15. Air intake

1

2

3

4

5

6

7

8

9

10

12

13

11

14

15

Loading...

Loading...