56 Fuel System Troubleshooting TP-6903 5/16a

3.10. Rough, Unstable, or Incorrect

Engine Speed and Stalling

Definition: The engine runs unevenly when under no

load. If severe enough, the engine may shake. The

engine speed may vary in rpm. Either condition may be

severe enough to stall the engine.

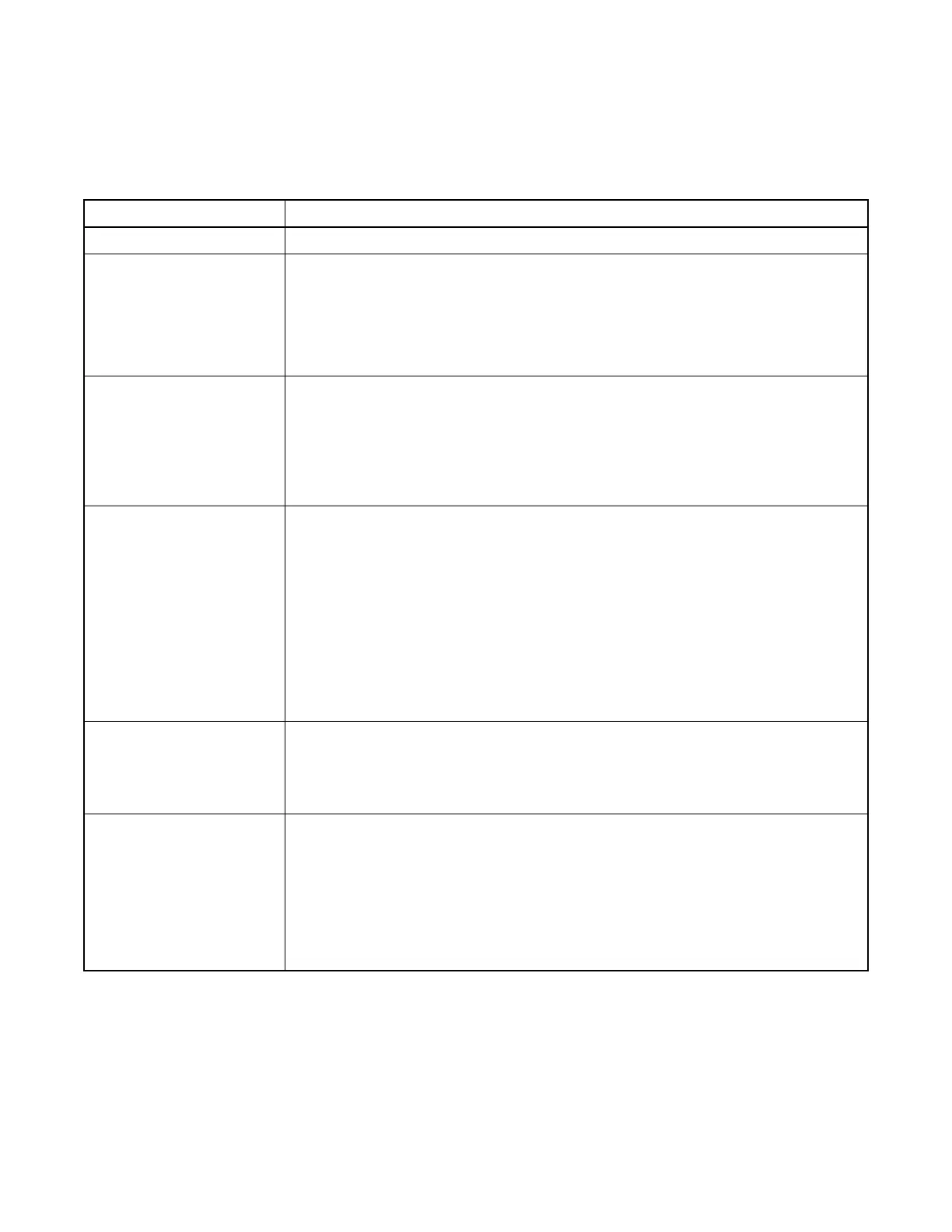

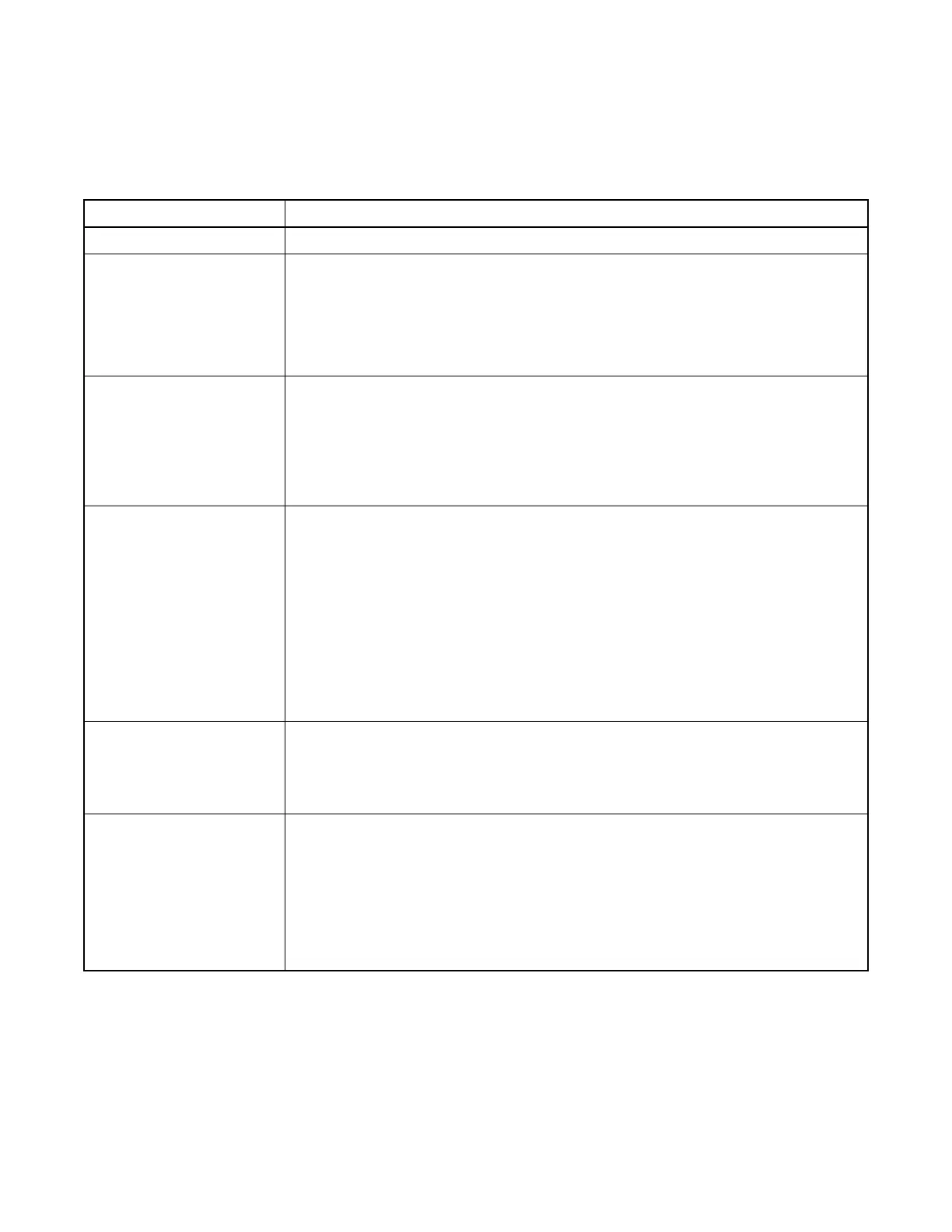

Figure 3-12 Engine Speed and Stalling Troubleshooting

Definition: Checks Action

Preliminary Check None.

Sensor Checks

Check the Heated Exhaust Gas Oxygen Sensor (HEGO) performance:

Check for silicone contamination from fuel or improperly used sealant. If contaminated,

the sensor may have a white powdery coating resulting in a high but false signal voltage

(rich exhaust indication). The ECM will reduce the amount of fuel delivered to the engine

causing a severe performance problem.

Check the Temperature Manifold Absolute Pressure (TMAP) sensor response and

accuracy.

Fuel System Checks

Check for rich or lean symptom that causes the condition.

Monitoring the HEGO sensor will help identify the problem.

Verify proper operation of the fuel pressure regulator.

Perform a cylinder compression test. Refer to Engine Service Manual.

Check the regulator fuel pressure.

Check the fuel pressure regulator, air-fuel mixer and throttle body for proper installation

and leakage.

Ignition System Checks

Check for proper ignition output voltage with a spark tester.

Verify that the spark plugs are the correct type and properly gapped.

Remove the plugs and inspect them for the following conditions:

o Wet plugs (oil fouling).

o Cracks.

o Wear.

o Improper gap.

o Burned electrodes.

o Blistered insulators.

o Heavy deposits.

Check the spark plug leads by connecting an ohmmeter to the ends of each lead in

question. If the meter reads over 15,000 ohms, replace the leads.

Additional Checks

Check for vacuum leaks. Vacuum leaks can cause poor engine performance.

Check that the ECM grounds are clean, tight, and in their proper locations.

Check that the battery cables and ground straps are clean and secure.

Erratic voltage may cause all sensor readings to be skewed resulting in poor engine

performance.

Engine Mechanical Check

Check the engine for:

Broken motor mounts.

Improper valve timing.

Low compression.

Improper valve clearance.

Worn rocker arms.

Broken or weak valve springs.

Worn camshaft lobes.

Loading...

Loading...