7

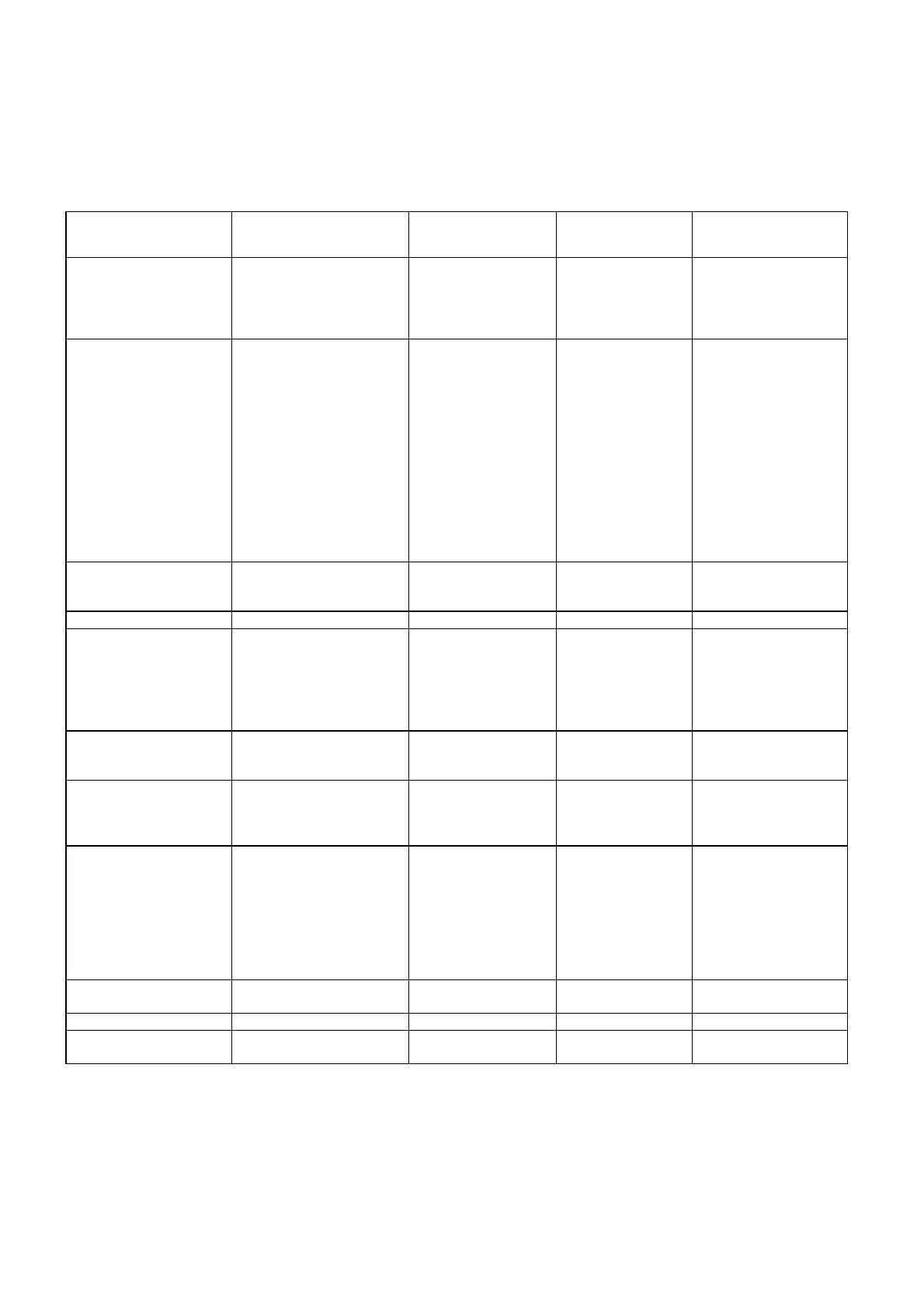

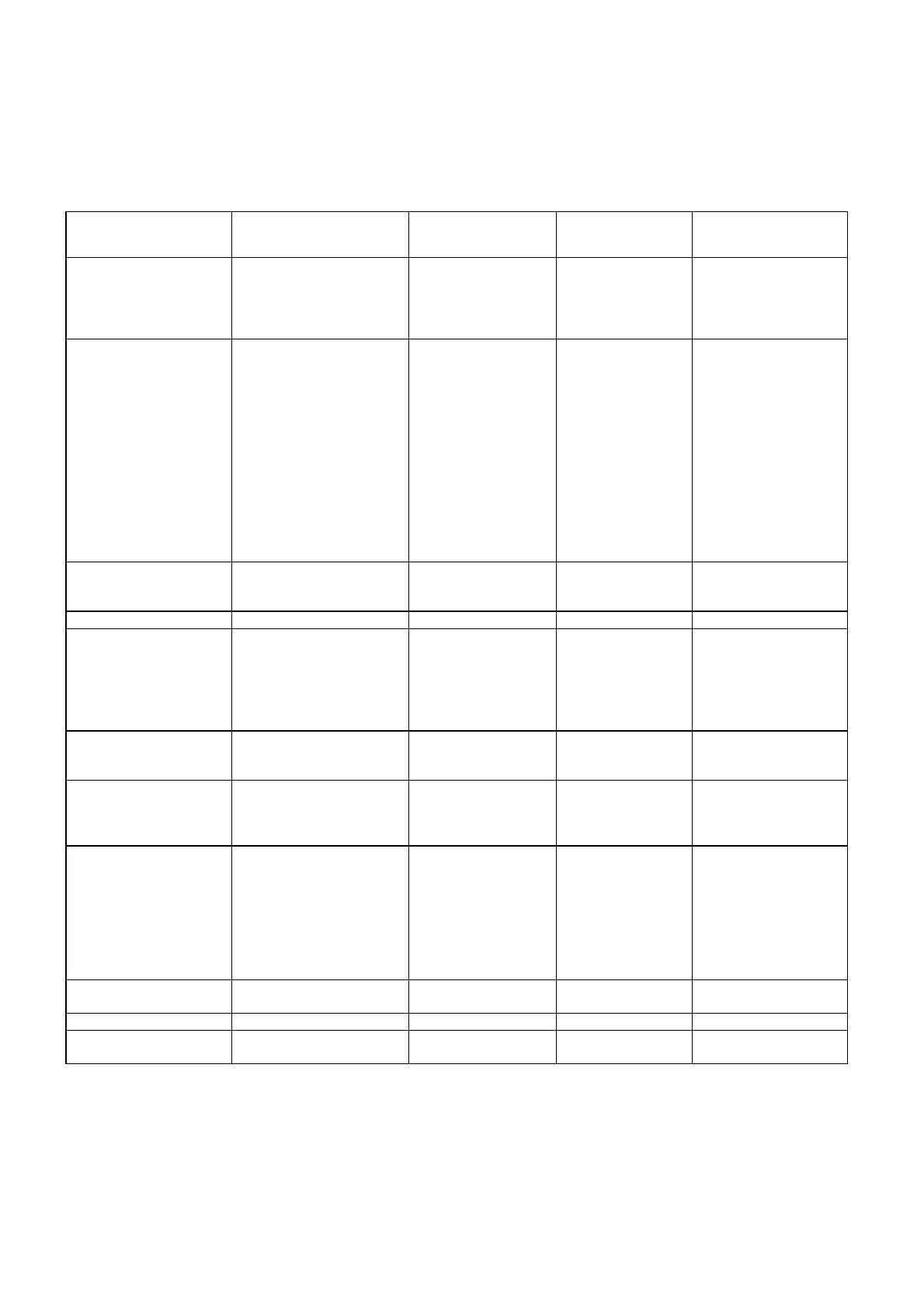

Cleaning Schedule

KOLBE –Mincer TW/SW 98/100

Important! Read and observe the operating manual!

Processes Cleaning products Methods Equipment Instructions

Coarse cleaning,

removal of product

residue, if necessary

after removing the

small parts

manual,

mechanical

spatula,

scraper

Start immediately

after the end of

production

Thorough cleaning,

alkaline

If necessary instead of

alkaline cleaning, acidic

cleaning

2-5 %, for example:

Henkel Hygiene –

• P3-topax 19

• P3-topax 66

Messrs. Goldschmidt –

• Somplex grease

dissolver

For aluminium parts, e.g.

Henkel Hygiene –

• 2-5% P3-topax 12

Messrs. Goldschmidt –

• Somplex F

foam for manual;

dwell time approx.

15 minutes

low pressure

foam unit,

brush, tank, hand

spray

Rinse water low pressure less low pressure

than 30 bar unit

temperature 50-60°C water hose

Check optical cleanliness

Thorough cleaning, For example: foam or manual; Low pressure If necessary, instead

acidic Henkel Hygiene - dwell time approx. foam unit, of alkaline cleaning.

• 3-6 % P3-topax 56

15 minutes hand spray, Follow manufacturer’s

Messrs. Goldschmidt –

• Somplex acidic foam

brush to remove

lime deposits

instructions; check

critical points and

problem areas.

Rinse

water low pressure less

than 30 bar

temperature 50-60ºC

low pressure

unit, water hose

Check optical cleanliness Follow manufacturer’s

instructions; check

critical points and

problem areas.

Disinfect As per product data sheet spray, foam, low pressure After completing all

0,5-2 %, for example: dwell time as per foam unit, the cleaning work in

Henkel Hygiene - product data sheet spray gun the room.

• P3-topax 99

• P3-topax 91

Messrs. Goldschmidt -

• TEGO 2000

• TEGO IMC

Final rinse rinking water low pressure low pressure

less than 30 bar unit, water hose

Dry

Care P3-care oil spray spray gun External surfaces

of the machine.

This cleaning schedule only applies for machines which are made predominantly of stainless steel. If other materials

are used, coordination with the relevant cleaning product manufacturer is required. The details given in the cleaning

schedule refer to single-shift operation, for multiple shift operation the cleaning intervals are to be adjusted accordingly.

Loading...

Loading...