8

Cleaning Instructions

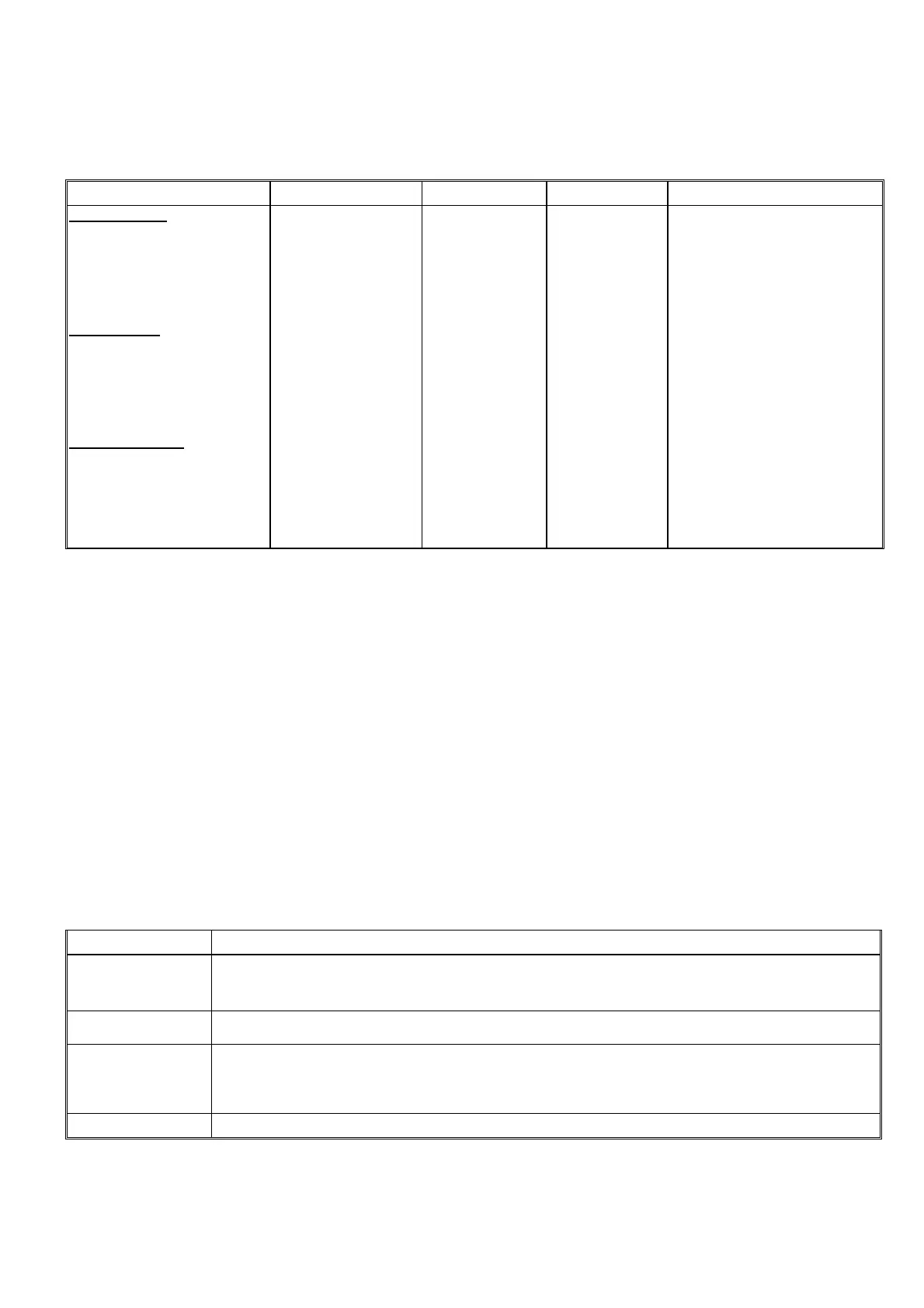

KOLBE – Mincer TW/SW 98/100

Machine zones which require special and careful cleaning

Cleaning zones Cleaning products Methods Equipment Instructions

Mincer casing:

- Mincer worm, cutting set and

removable mincer casing

-Securing screws of mincer

casing

see cleaning schedule manual,

mechanical

brush, paintbrush Remove parts and clean them in

a tank or dishwasher.

Clean the thread thoroughly with

the brush or paintbrush.

Mincer stand:

- External areas and mincer

bowl

- Undercarriage of mincer and

removable tray (if available)

see cleaning schedule manual,

mechanical

brush, paintbrush Clean external and internal

surfaces as well as the

undercarriage thoroughly with the

brush or paintbrush.

Inspection cover:

- Inspection cover, rear see cleaning schedule manual,

mechanical

brush, paintbrush Clean outer contours of

inspection cover thoroughly with

the brush or paintbrush.

9. Maintenance and Servicing

Important!

Disconnect the main power supply before completing

any maintenance and servicing work (remove the plug,

turn the main switch off).

- Follow safety instructions for maintenance and servicing

work

- Faults which are caused by inadequate or improper

maintenance may cause high repair costs and long

down times of the machine. Regular maintenance is

therefore essential.

- The reliability and the service life of the machine depend

on many factors, including the machine properly

maintained.

- The following table contains schedules, inspection and

maintenance instructions for the normal use of the

machine.

- As a result of the wide variety of operating conditions we

cannot state in advance how often a wear check,

maintenance and servicing work will be required. An

appropriate servicing schedule is to be drawn up on the

basis of your operating conditions.

- Our specialists will be pleased to help you with further

advice.

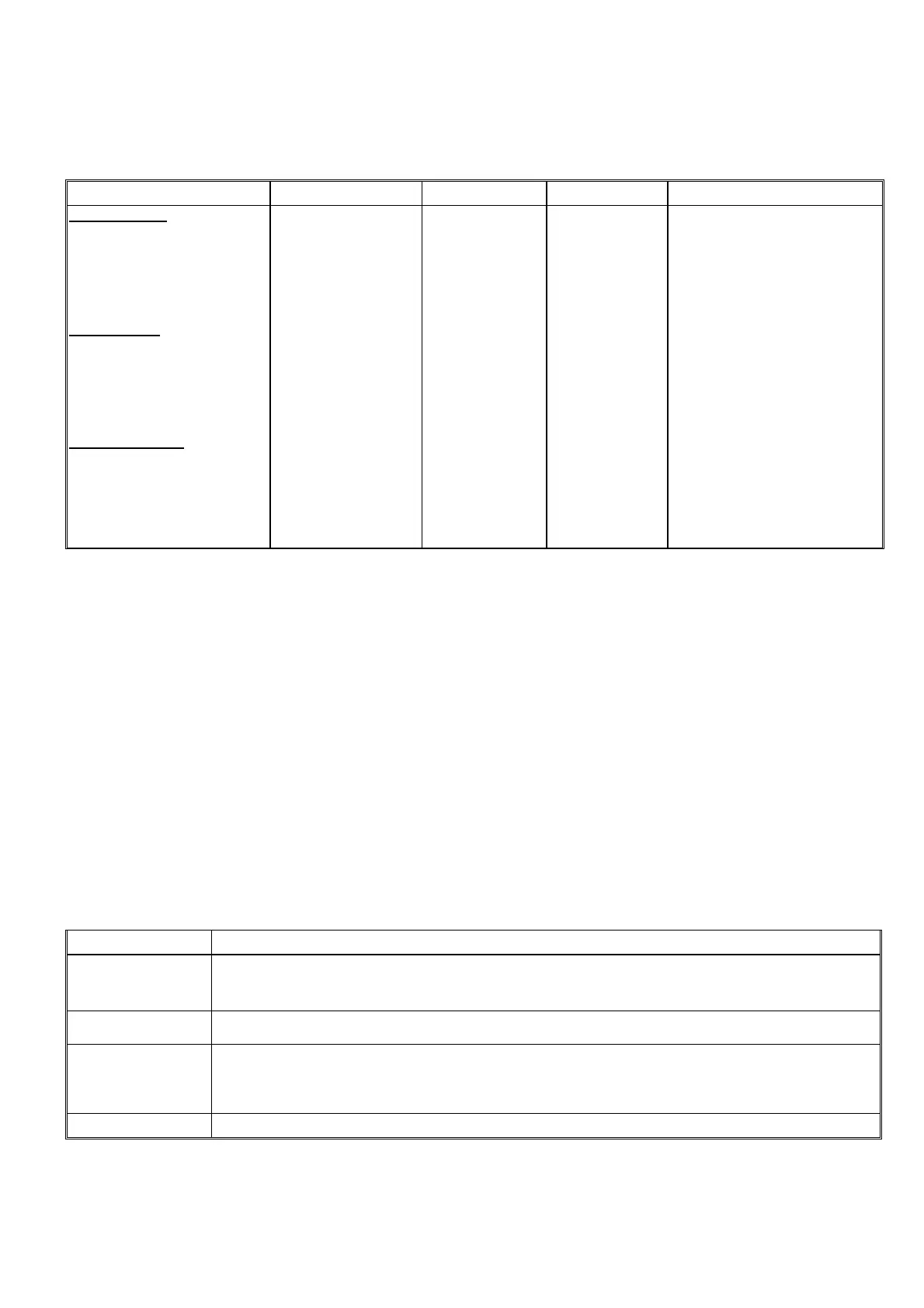

9.1

Maintenance and Servicing List

Inspection Intervals

Inspection Points and Maintenance Instructions

Every day - Check the level of wear on the moving knife (shape bladeness) and cutting set

Perform full cleaning according to the cleaning plan

Every month - Check the level of wear on the knife journal on the mincer worm and replace it if necessary

Every year - Check the level of wear of mincer worm and mincer housing and replace it if necessary

- Check the gear bearings and replace ball bearings if necessary

- Check the motor bearings and replace ball bearings if necessary

Every 2 - 3 years - Change the gearbox oil

Loading...

Loading...