2-53

PC210/240-ENG

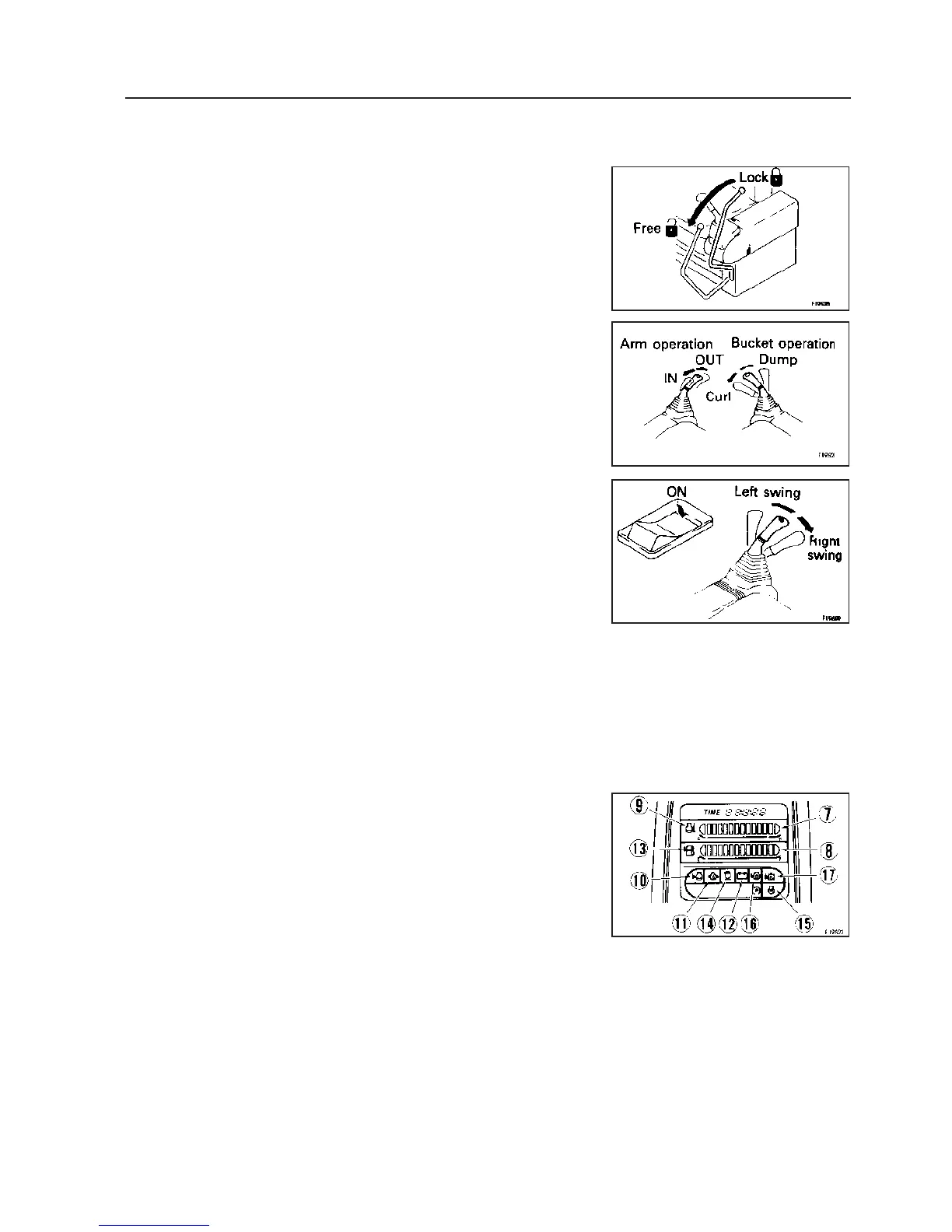

3. Set the safety lock lever c to the FREE position, and raise the

bucket from the ground.

4. Operate bucket control lever v and arm control lever b slowly to

move the bucket cylinder and arm cylinder to the end of the stroke.

5. Carry out bucket and arm operation for 5 minutes at full stroke, alter-

nating between bucket operation and arm operation at 30 second

intervals.

If the swing lock switch n is set to the ON (actuated) position and

swing control lever b is operated at full stroke, oil temperature rise

can be increased earlier.

NOTICE

When the work equipment is retracted, take care that it does not

interfere with the machine body or ground.

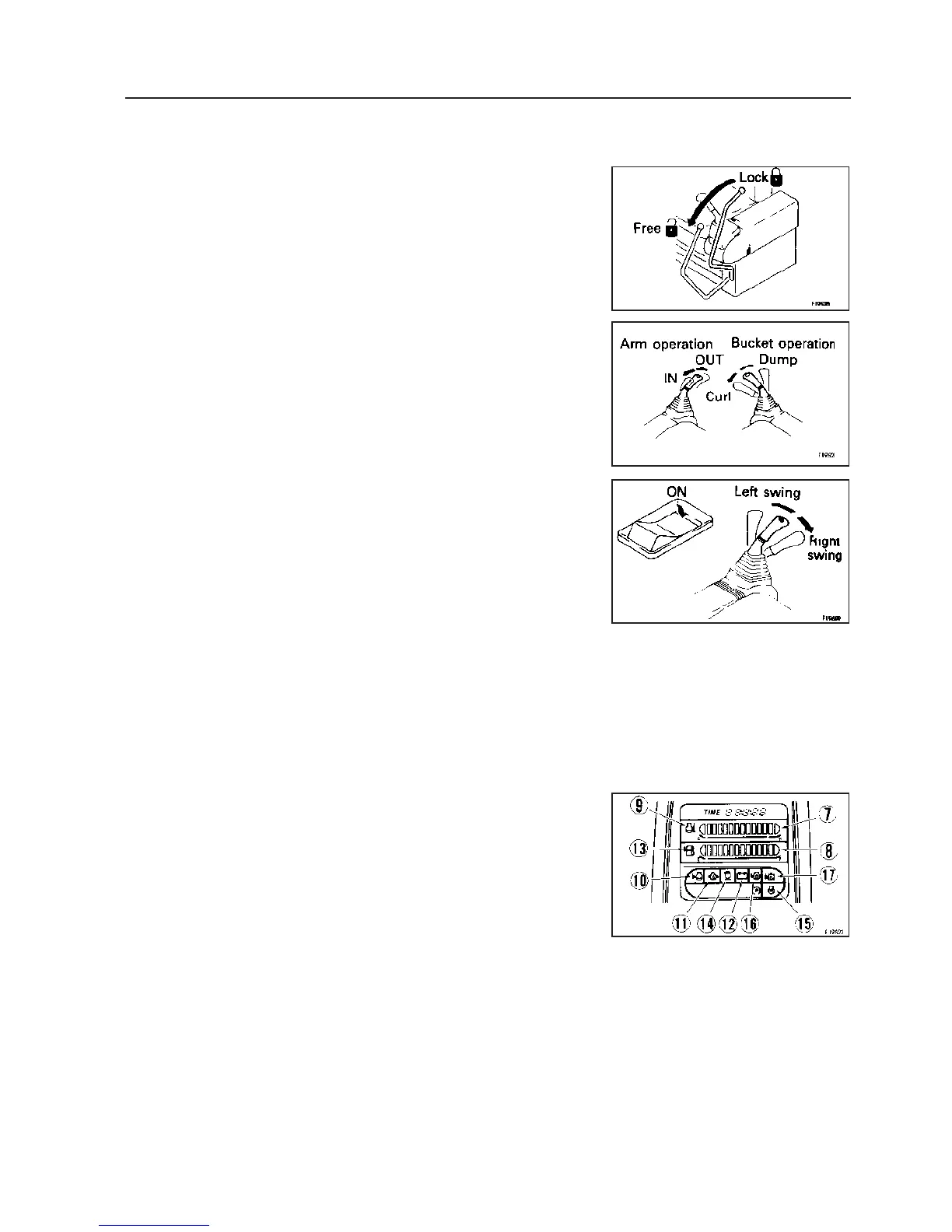

6. After carrying out the warming-up operation, check that each gauge

and monitor lamp is in the following condition.

• Engine water temperature gauge g: Inside green range

• Fuel gauge h: Inside green range

• Engine water temperature monitor i: OUT

• Radiator water level monitor j: OUT

• Engine oil pressure monitor k: OUT

• Charge level monitor l: OUT

• Fuel level monitor m: OUT

• Air cleaner clogging monitor n: OUT

• Engine pre-heating monitor o: OUT

• Engine oil level monitor p: OUT

• Hydraulic oil level monitor q: OUT

7. Check that there is no abnormal exhaust gas colour, noise, or vibra-

tion. If any abnormality is found, repair it.

12. OPERATION

Loading...

Loading...