Kortho Hot Quickcoder User Manual

7

2 GENERAL INTRODUCTION

The Hot Quickcoder (henceforth HQC) has been developed to apply small texts of one to three lines

(max. line length 25 mm) on a production line. The applications vary from loose products to a

continuous product (e.g. packaging film).

The text can be applied to a stationary or a moving product. The maximum permitted product speed

is 60 m/min. Approx. 250 impressions per minute can be produced.

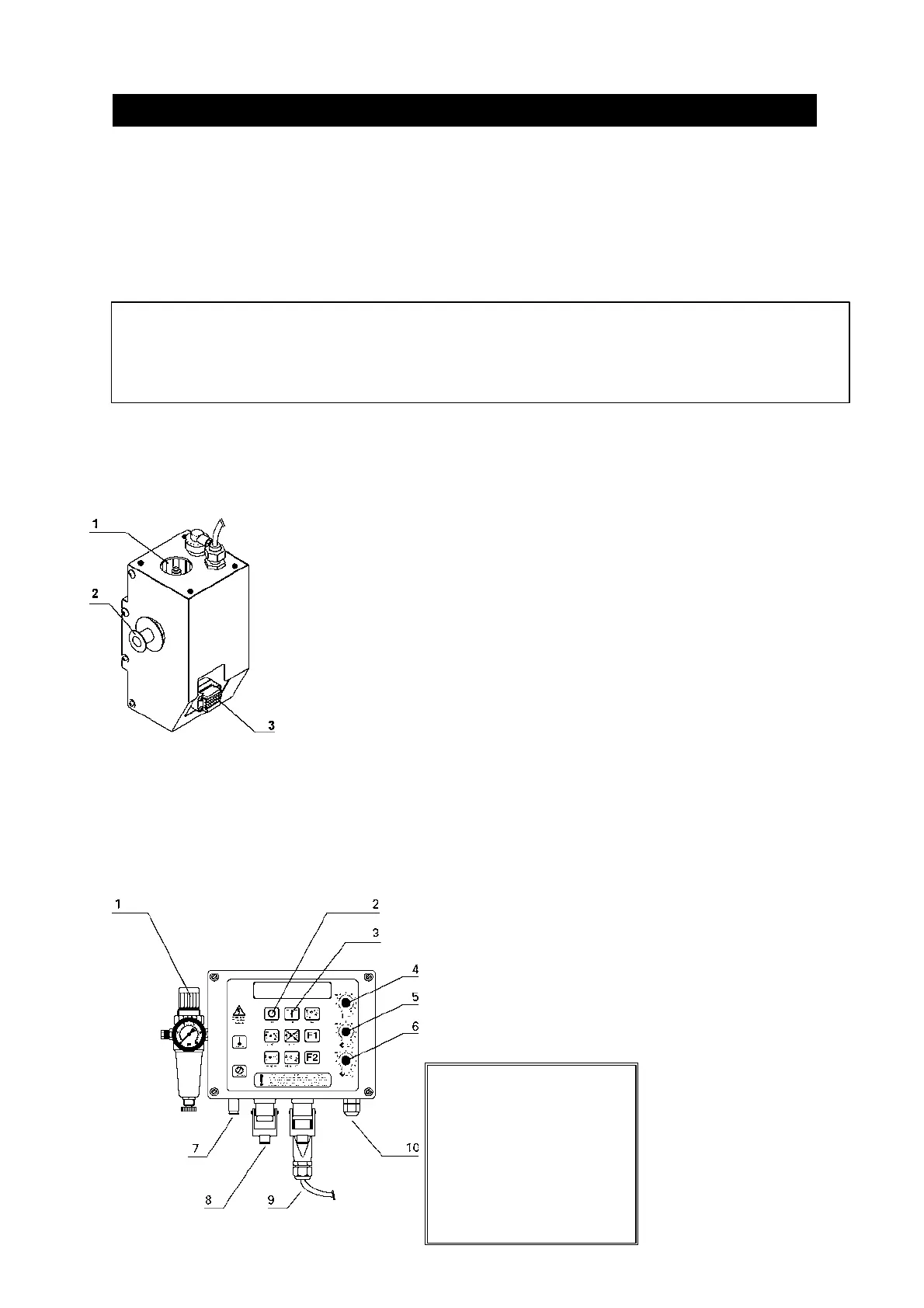

2.1 The Hot Quickcoder

Figure 1: The Hot Quickcoder

The code to be printed is applied to an exchangeable

text head via text characters or blocks. The text head

is inked with a Hotroll which only delivers the inked

(wax-based) at high temperature. The Hotroll is kept

at temperature in the heating ring of the HQC.

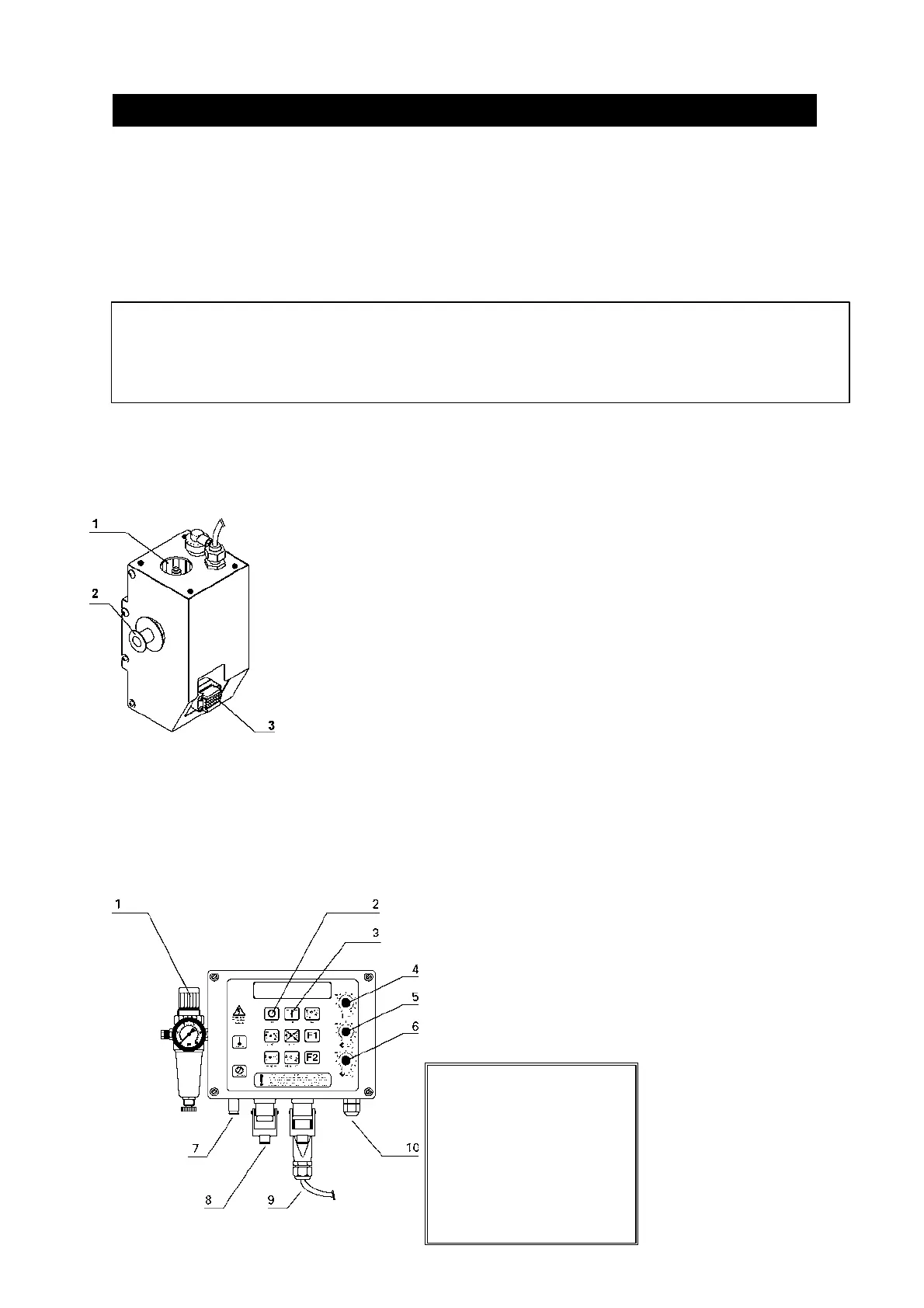

2.2 The Control box

A good print quality is achieved with a correct combination of stamping time, stamping pressure,

temperature of the text head and the setting of any counter-pressure plate.

Figure 2: The Control box

The stamping time

and temperature are

set with the buttons

on the Control box.

The stamping

pressure is set as

standard to 4 bar.

The impression can

be optimised using a

counter-pressure

plate, if there is one.

(In case film belts)

! WARNING:

After using the HQC, it cannot simply be deactivated. For the correct procedure read section 8

"Deactivating the Hot Quickcoder".

1 Preheating

2 Hotroll

3 Text head

1 Pressure setting

2 OFF button

3 ON button

4 Temperature setting

5 Pulse/time setting

6 Print/delay setting

7 HQC air connection

8 Mains power connection

9 Hot Quickcoder connection

10 Coupling nut

!!! NOTE !!!

The HQC air connection is

a rapid connection as

indicated in figure 2. Other

figures of the Control box

in this manual still show

the old connection.

Loading...

Loading...