7-24 BA 35203_04 * 3.0 * 35203_04_07_Wartung.fm

7 Maintenance

7.6 Lubrication work

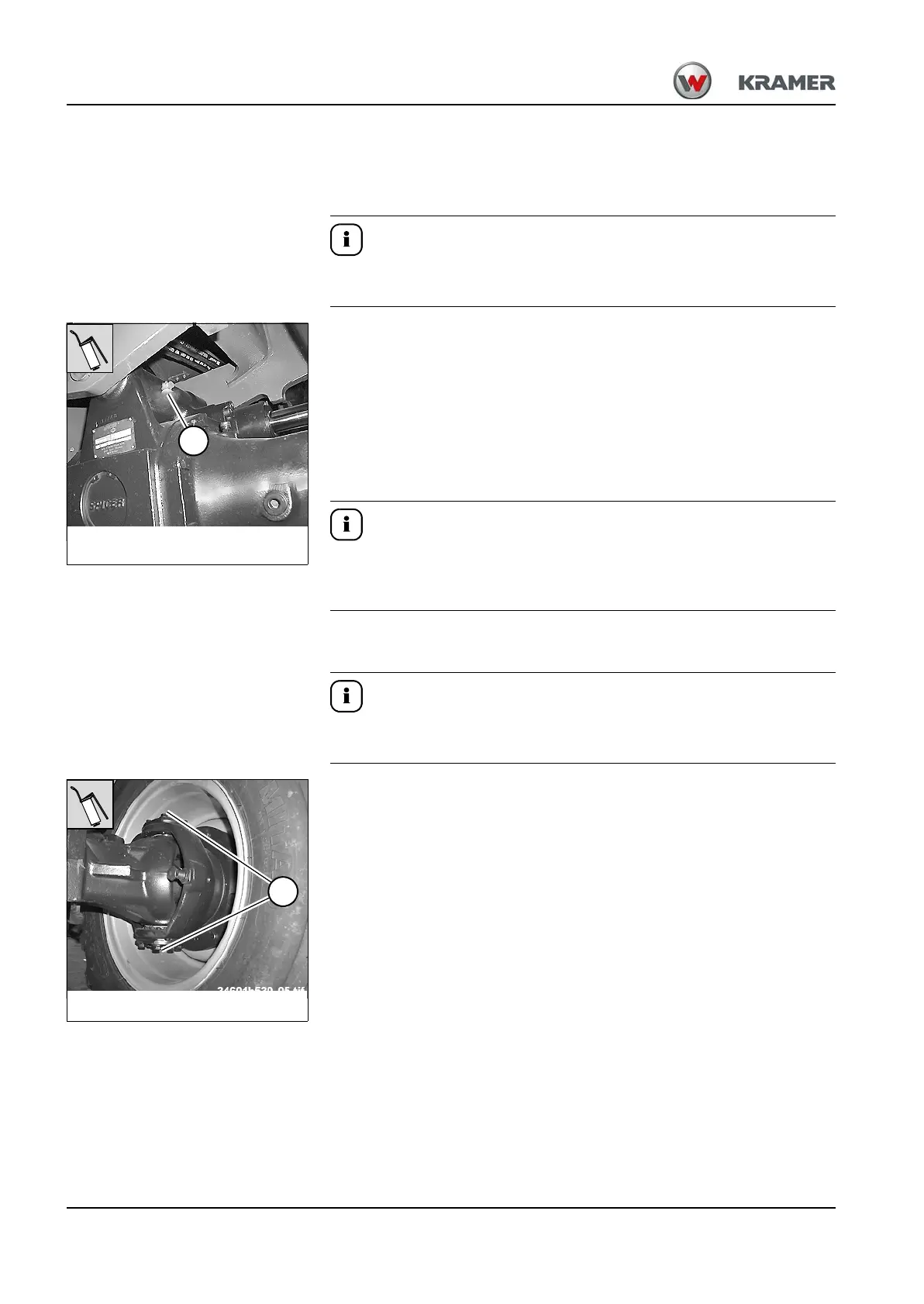

Lubricating the rear axle oscillation-type bearing

Maintenance intervals – see “Maintenance plan” on page 7-3.

Lubricant – see “Fluids and lubricants” on page 7-12.

1. Park the machine on level ground.

2. Apply the parking brake.

3. Secure the machine with a wheel chock.

4. Only raise the loader unit until all zerk fittings can be accessed without

any risk.

5. Stop the engine and remove the starting key.

6. Switch off the battery master switch (option).

7. Lubricate grease zerk A of the oscillation-type bearing.

A "remote lubrication" of the oscillating axle bearing is available. The zerk

fitting on the oscillating axle bearing is connected to a zerk fitting mounted

to the frame via a hose pipe.

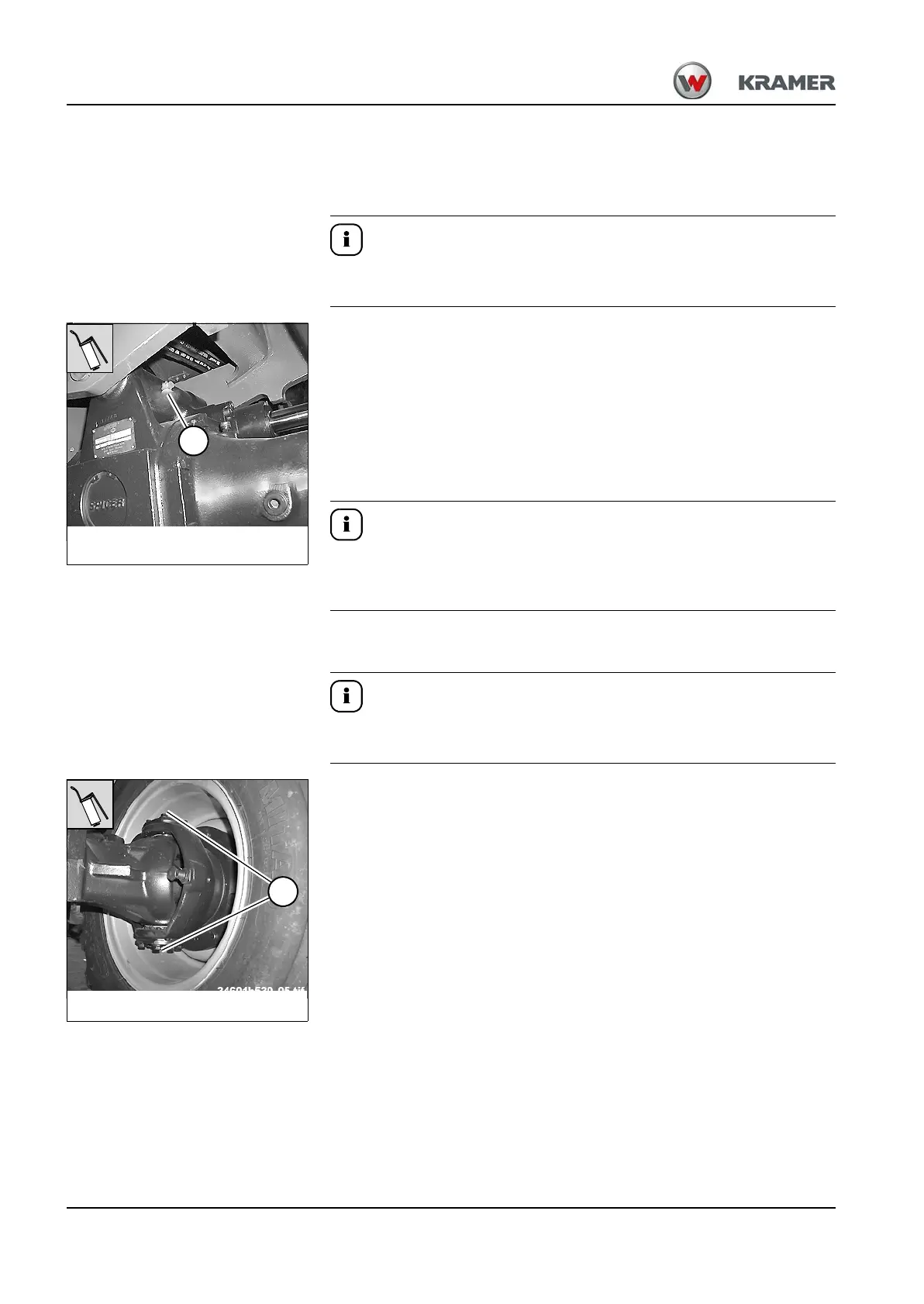

Lubricating the planetary drive bearing (front and rear axles)

Maintenance intervals – see “Maintenance plan” on page 7-3.

Lubricant – see “Fluids and lubricants” on page 7-12.

1. Park the machine on level ground.

2. Apply the parking brake.

3. Secure the machine with a wheel chock.

4. Only raise the loader unit until all zerk fittings can be accessed without

any risk.

5. Turn the steering wheel for better access.

6. Stop the engine and remove the starting key.

7. Switch off the battery master switch (option).

8. Lubricate zerk fittings B (2 x on each planetary drive bearing).

Loading...

Loading...