7

2

Drive Screws

a. Ensure you are using the correct screw size according to this chart:

Gauged Material

Thickness

Easy-Set

Stop Collar

Material

Thickness Stop

Screw Length

1/2 Range 1/2 1/2 1" (25 mm)

3/4 Range 3/4 3/4 1-1/4" (32 mm)

3/4 3/4 1-1/2" (38 mm)

1-1/2 Range 1½ 1½ 2-1/2" (64 mm)

For more information on screw selections, go to www.Kregtool.com/Screws or

simply scan the QR code on the side of your sample screw package.

Tip A 1" screw is recommended for most applications, but if your workpiece is

on the low end of the range, a 3/4" screw might be required to keep the screw tip

from protruding.

Note If your material thickness falls in the range, use the same setup

techniques as the 3/4" range with a 1-1/2" screw.

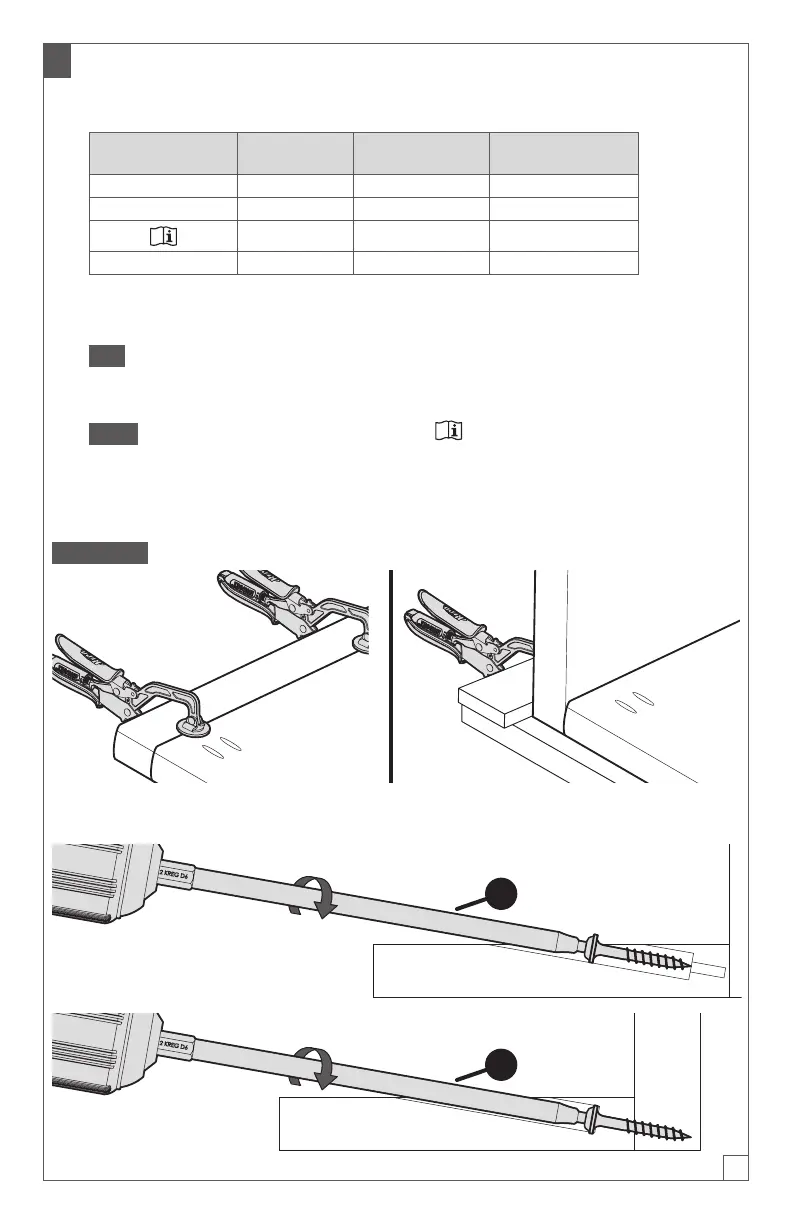

b. Clamp joints in place to ensure a better nished joint. These examples show face

joints and edge joints.

WARNING When drilling, always ensure the workpiece is clamped securely.

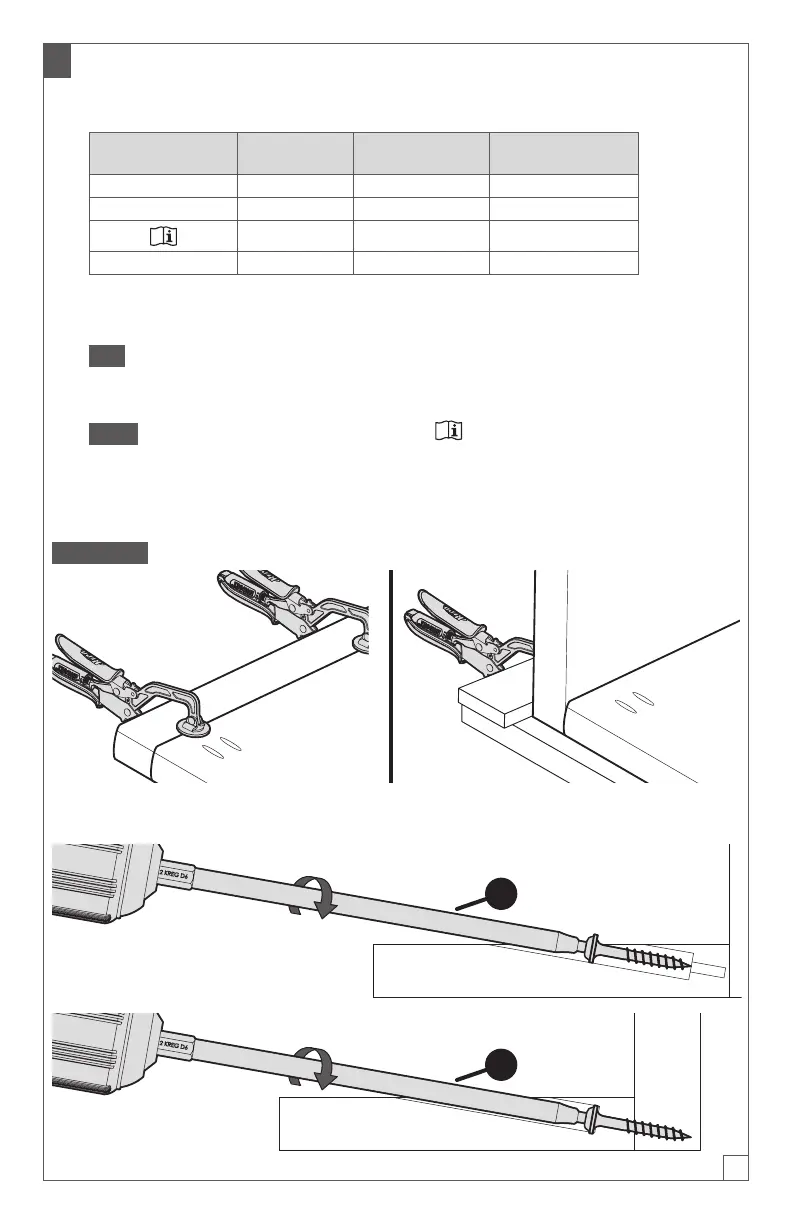

c. Place your screw on the driver tip (E), position the screw in the pocket hole, and

drive the screw until it is fully seated without overdriving.

E

E

Loading...

Loading...