4-

17

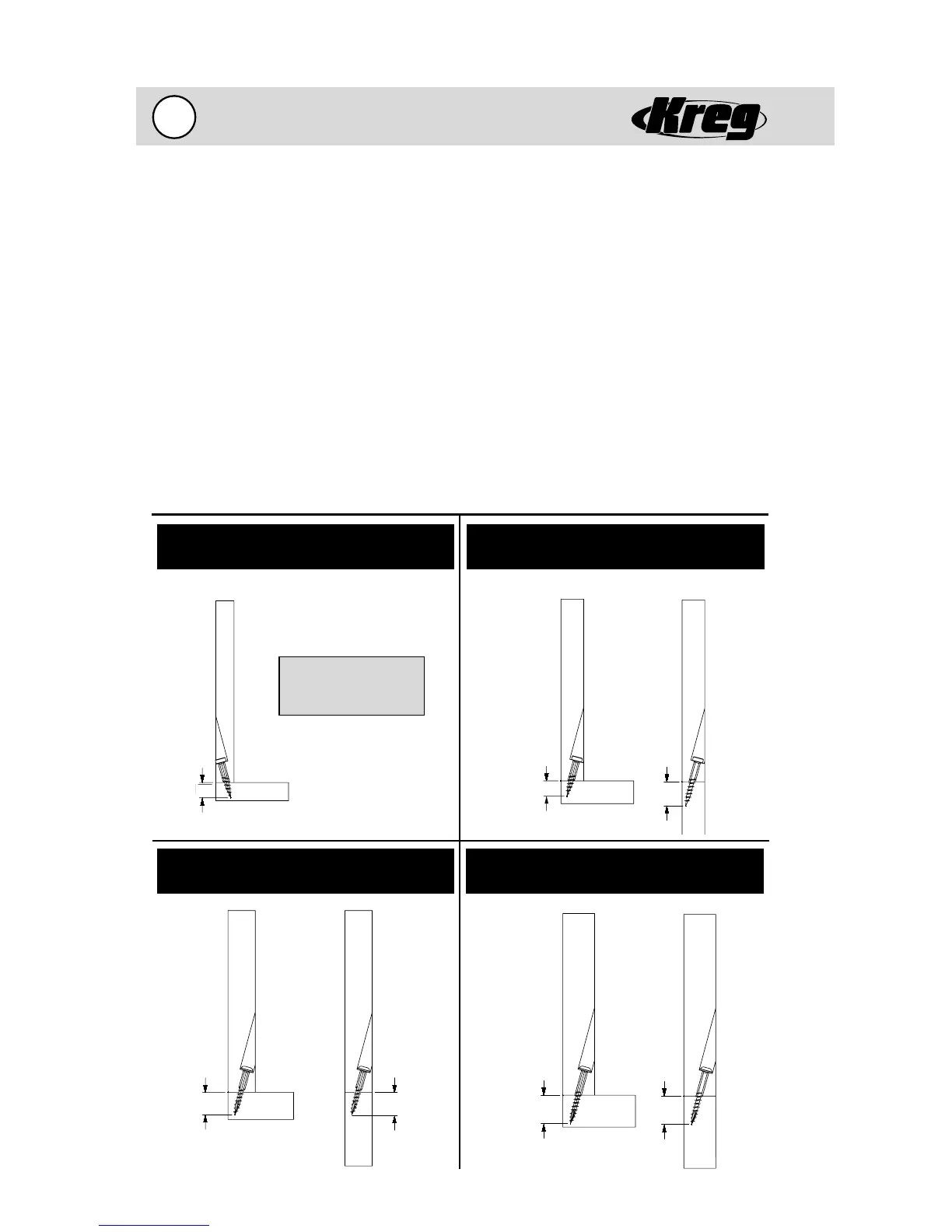

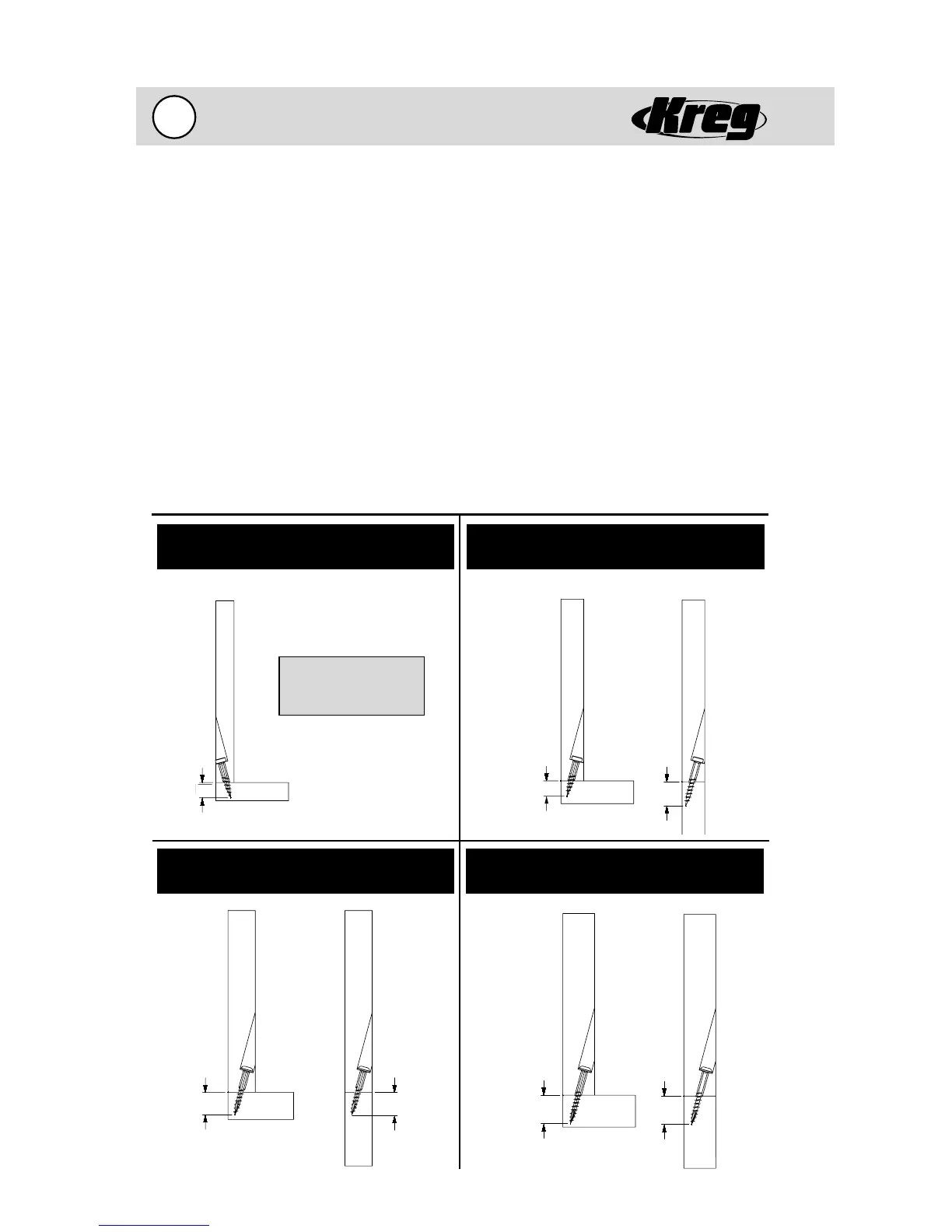

Selecting the Correct Screw for Your Application

Selecting the correct screw for your application is a function of three variables.

1. Jig setting - Set jig to the same setting as your wood thickness (ie. 3/4”

setting for 3/4” thick wood.

2. Drill bit depth collar setting - Set your drill bit to the standard setting

using the base of the jig or the chart at the bottom of page 18.

3. Screw length - Use the chart below to select the correct screw length.

The chart below helps to select the correct screw type when joining like thicknesses of

wood (ie. 3/4” to 3/4” material) in both a frame and right angle application. This chart

assumes that you are using the setting of the jig that corresponds to the material

thickness you are drilling, and that you are using the standard drill bit depth collar

settings posted at the bottom right of page 18. These are simply standard guidelines

for screw penetration... we always recommend that you test your desired joint in scrap

material before drilling and assembling final pocket holes.

Joining 5/8” to 5/8” material

1” or 1-1/4” recommended screw length

Joining 3/4” to 3/4” material

1-1/4” recommended screw length

Joining 7/8” to 7/8” material

1-1/2” recommended screw length

Joining 1/2” to 1/2” material

1” recommended screw length

5/8” Material

5/8” Material

7/8” Material

7/8” Material

3/4” Material

3/4” Material

Selecting the Correct Screw

1/2” Material

We do not recommend

frame joinery of

1/2” to 1/2” material.

Loading...

Loading...