Head Styles

The washer head (SML) screw is our most

popular head style as it provides the largest

amount of surface area to seat firmly in the

bottom of the pocket. Available in both fine

or coarse thread, this head style is highly

recommended if the material the pocket is

drilled into is soft such as plywood or pine.

The large washer head assures that the

screw is not overdriven in the bottom of

the pocket.

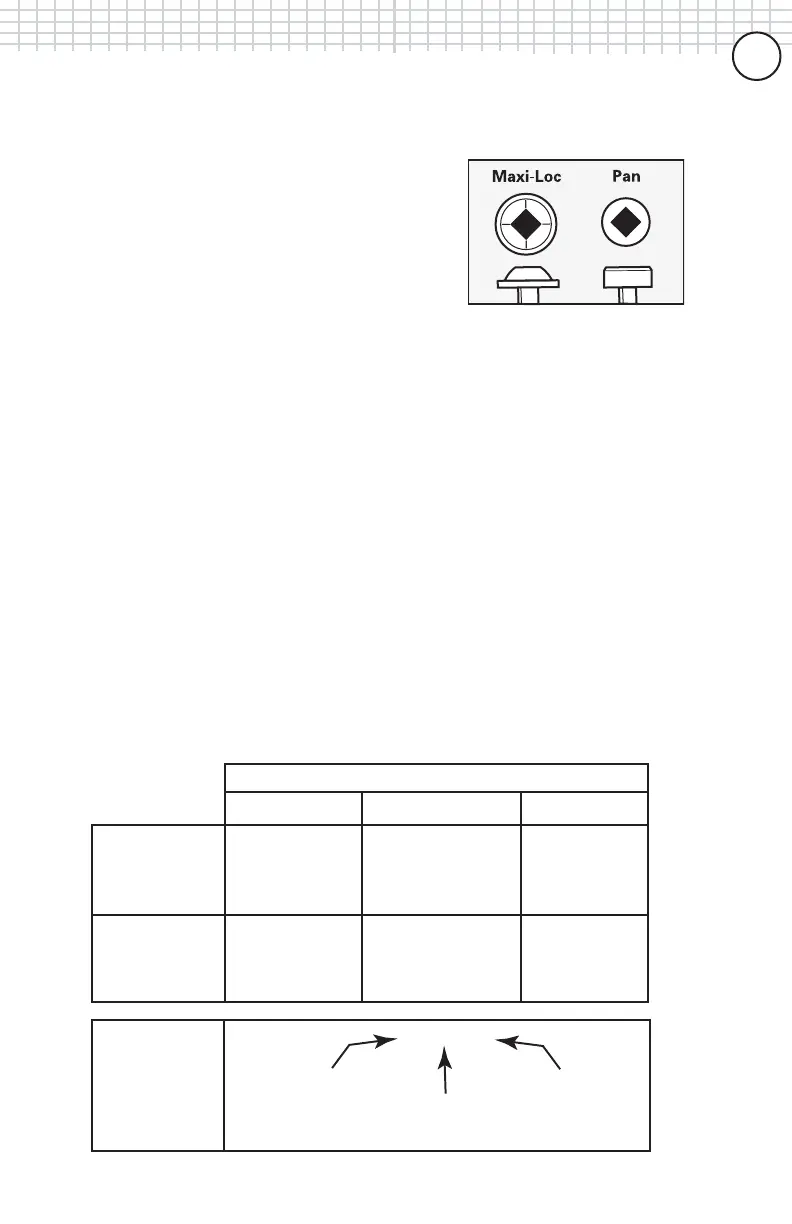

Screw Length

There are four thread lengths most commonly used in pocket hole joinery;

1", 1-1/4", 1-1/2" and 2-1/2". Choosing the correct screw length

depends on the setting of your jig and the depth at which you drill the pocket

hole. Many times you will be joining 3/4" material to 3/4" material, 1/2" material

to 1/2" or 1-1/2" material to 1-1/2" material. The chart below helps you select

the screw to use in these situations.

The second available head style is the pan head (SPS). The pan head is slightly

smaller in both head and shank diameter than the washer head screw and is a

good alternative to the washer head screw if both mating workpieces are made

of extremely hard woods. The pan head style is also of benefit in the 1" length as

it allows one to join 1/2" stock and easily seat the screw head below flush.

Hardwoods

(Oak, Maple,

Walnut, etc.)

Softwoods,

(playwood,

MDF, pine,

etc.)

Material Thicknesses Being Joined

1/2” to 1/2” 3/4” to 3/4” 1-1/2” to 1-1/2”

*SPS-F1

SPS-F1(W)

*SPS-C1

SML-C1

*SML-F125

SML-F125(W)

SML-F150

SPS-F125

SPS-F125(W)

SPS-F150

*SML-C125

SML-HL125

SML-C125(W)

SML-C150

SML-C150(W)

*SML-C250(W)

SML-C250

*SML-C250(W)

SML-C250

SML-F125

SML = WASHER HD.

SPS = PAN HD.

1 = 1”

125 = 1-1/4”

150 = 1-1/2”

250 = 2-1/2”

F = FINE

C = COARSE

HL = HI- LO

KEY

* - denotes

preferred

screw type

(W) - denotes

weather

resistant

coating

Figure

(23)

Figure

(24)

1616

1616

16

Loading...

Loading...