1/2

The K2000 Kreg Jig

®

is designed with standard settings that allow one to

easily join 1/2”, 3/4” and 1-1/2” thick material. These three material thick-

nesses account for approximately 90 percent of the materials commonly used

today in woodworking. If your material thickness falls between one of the

standard settings, for example 1-1/4" stock, simply use the setting closest to

your material thickness or build your own spacer block as shown on page 10.

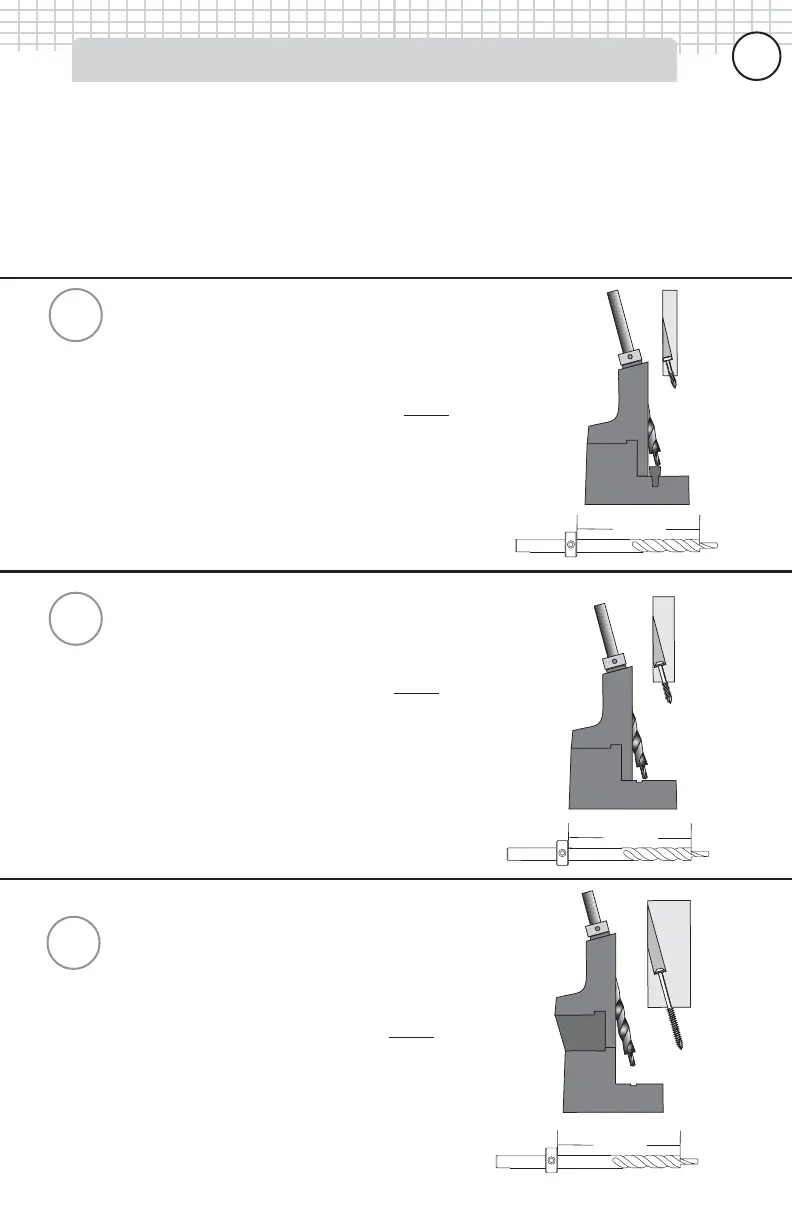

Using the K2000 Kreg Jig®

3-5/16”

4-1/4”

3/4

1.5

To join 1/2” thick material.

1. Attach upright to base of jig with short T-bolt provided.

2. Press step block into groove on the base of the jig.

3. Set depth collar to 3-5/16” from the

STEP

of

the drill bit.

4. Rest material on step block, adjust toggle pressure and

clamp into place.

5. Drill pocket hole. Use 1” screw to join 1/2” to

another 1/2” thick workpiece.

To join 3/4” thick material.

1. Attach upright to base of jig with short T-bolt provided.

2. Set depth collar to 3-1/2” from the

STEP

of the drill bit.

3. Rest material on base of jig, adjust toggle pressure and

clamp into place.

4. Drill pocket hole. Use 1-1/4” screw to join 3/4” to

another 3/4” thick workpiece.

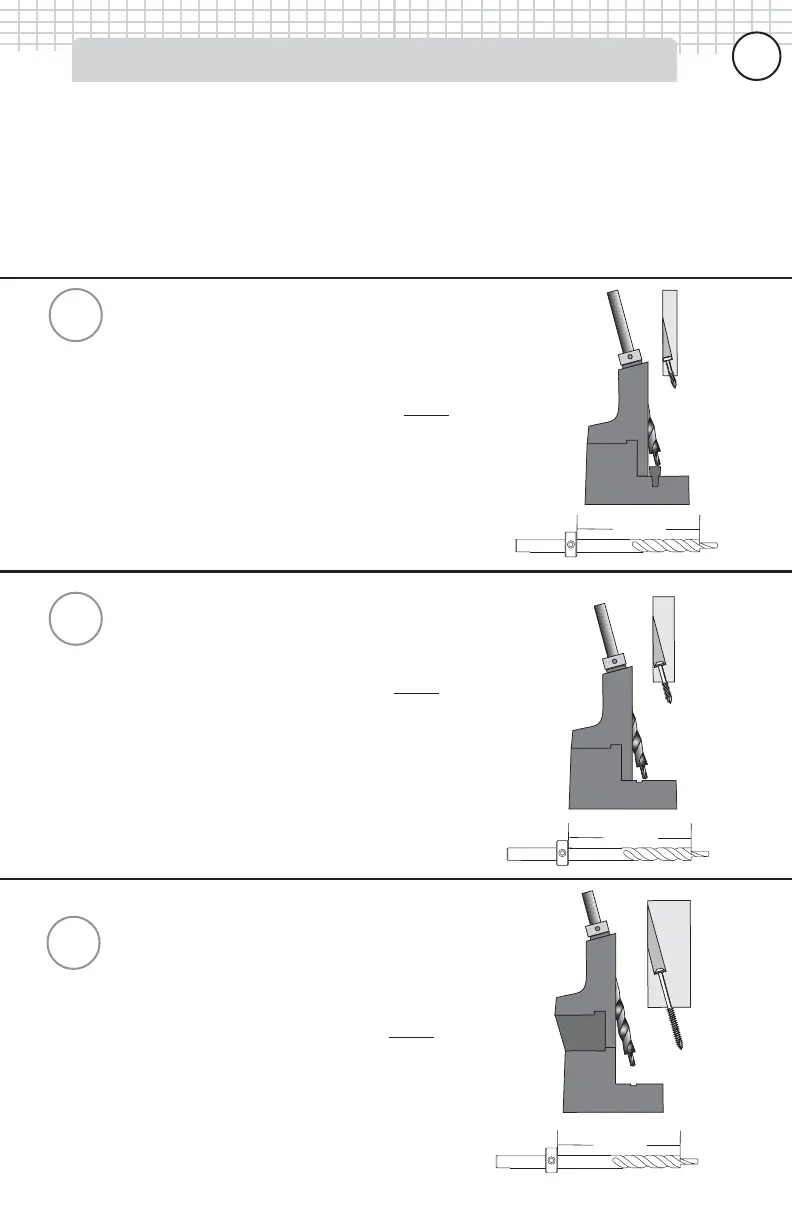

To join 1-1/2” thick material.

1. Attach riser block and upright to base of jig with

long T-bolt provided.

2. Set depth collar to 4-1/4” from the

STEP

of the drill bit.

3. Rest material on base of jig, adjust toggle pressure and

clamp into place.

4. Drill pocket hole. Use 2-1/2” screw to join 1-1/2” to

another 1-1/2” thick workpiece.

3-1/2”

Figure

(8)

Figure

(9)

Figure

(10)

88

88

8

Loading...

Loading...