Settings

261

Pos: 93.47 /BA/Ei nstellungen/Groß packenpresse/N adeleinstell ungen/Position Na deln – Preß kolben prüfe n @ 150\mod_ 13620573810 79_78.docx @ 134 3393 @ 2 @ 1

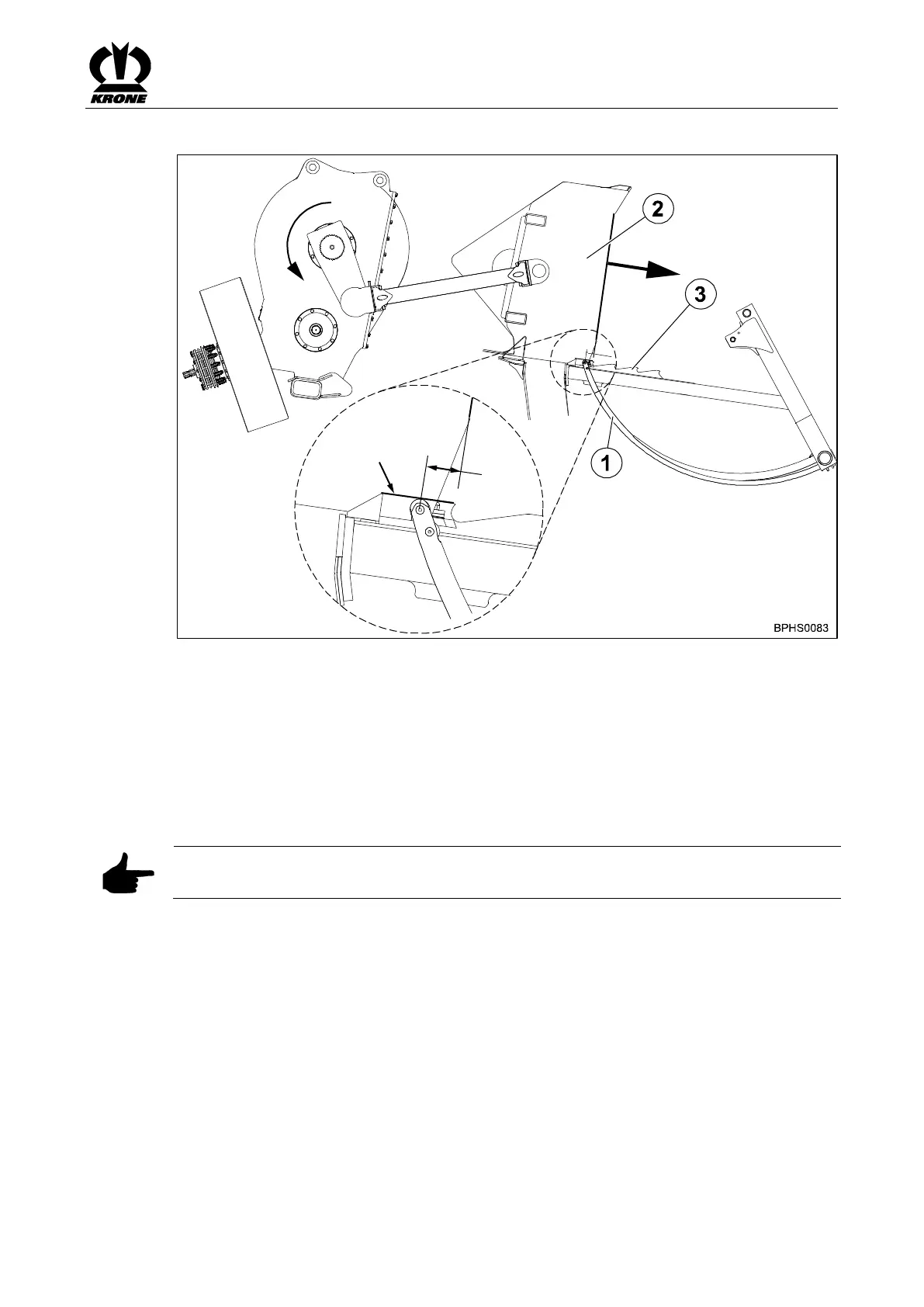

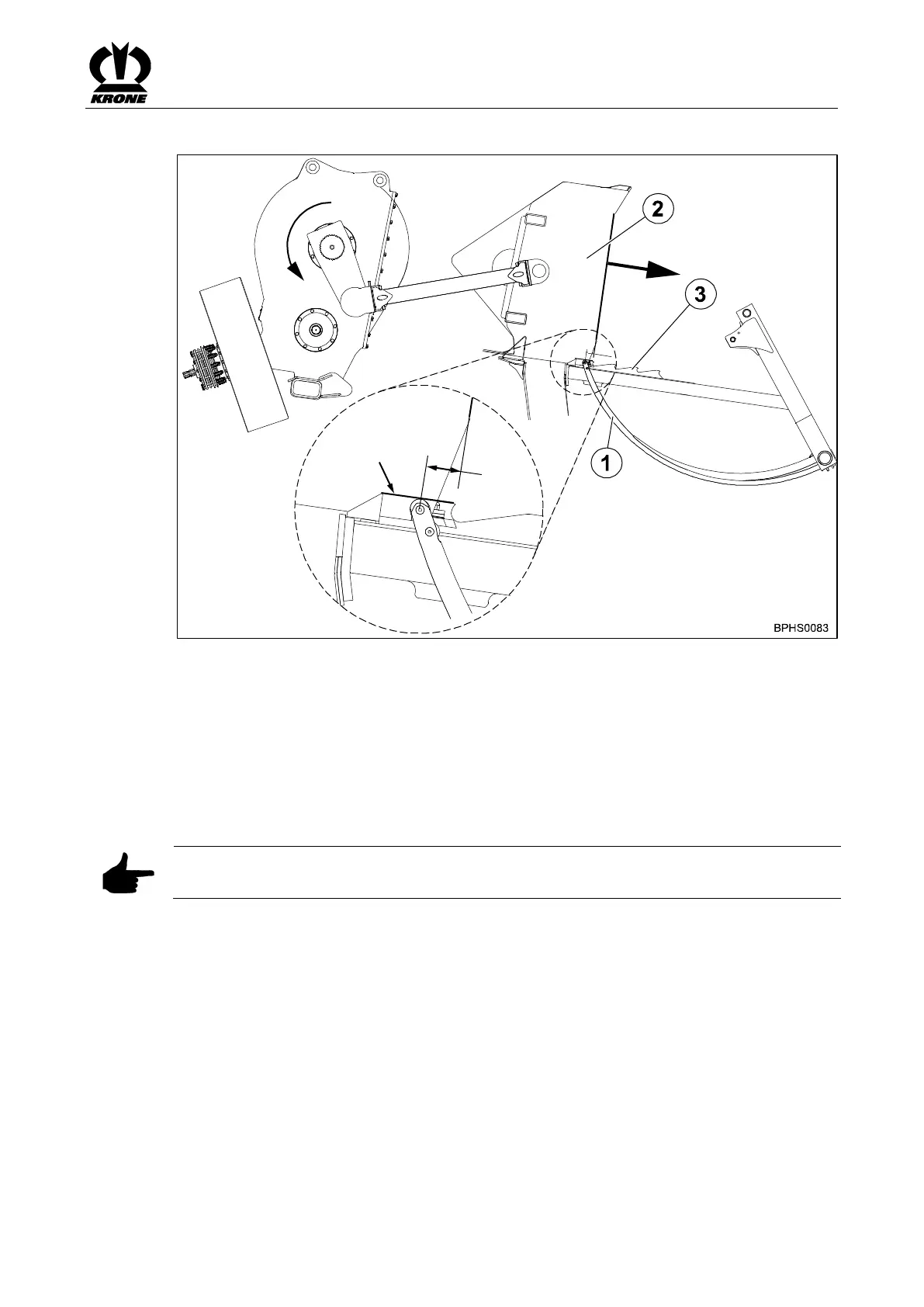

19.6 Checking / adjusting position of needles – baling ram

Fig.

Check:

• Completely release spring tension of the needle yoke brake

• Manually actuate the tying process while the machine is at a standstill

• Manually rotate flywheel mass until the needle points (1) have reached the upper edge (b)

of the fixed retainers (3) in the bale channel floor

• Block the needles in this position and apply the flywheel brake

• The dimension “a” (baling ram front edge to needle tip) must be 60 – 90 mm

If this is not the case:

Note

Set dimension "a" only in baling direction of the baling ram (2) (see arrow in fig.).

• Remove drive cardan shaft from the knotter gear

• Manually rotate flywheel mass (baling ram moves in baling direction) until dimension

a = 60 – 90 mm

• Attach drive cardan shaft to the knotter shaft and secure

• Manually actuate the tying process again while the machine is at a standstill

• Check position of needles – baling ram again

• Set spring tension of the needle yoke brake

Pos: 93.48 /La yout Module /---------------Seitenumbruch---------------- @ 0\mod_11961 75311226_0.doc x @ 4165 @ @ 1

Loading...

Loading...